FAQ.

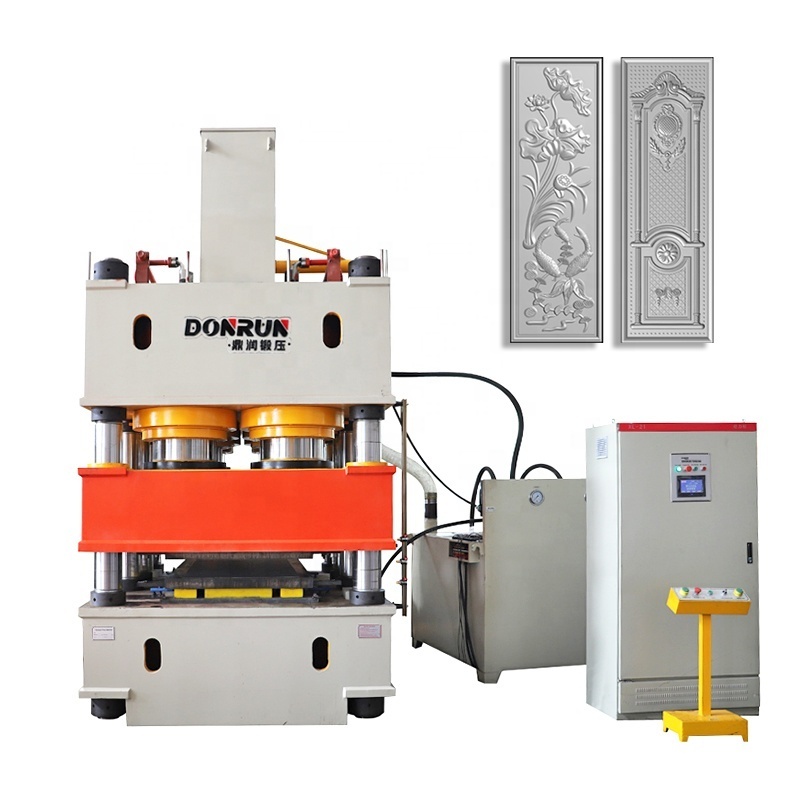

1.What's the price and specification of hydraulic press machine?

Re: Dingrun always provide high quality machine, as we know,oversea market is more important and difficult than domestic market because of communication time costing after sales.So always,our machines has enough quality standard to make sure the machine can work more than the real warranty period. In this way ,we will save a lot and think advance for the clients. Please let me know the utensil diameter and height, the pictures and drawing will be better, so that we can check and recommend suitable machine for you.

2. How about your machine quality?We are worry about the quality.

Re: Dingrun is a mature brand in China. through our several years research in technology , our design including strcture and detailed sercurity and precision has enhanced greatly, and can match all the CE standard or mor strict standard.Our machines distribute worldwide to about 20 countries where there are metal plate industry.And where there are our machines, there are good reputation and terminal user satisfaction.

3. May I send samples to test? Do you have a test fee or not?

Re: Yes, if you could send us samples, it will be better. For testing, we have to customize the moulds according to your products,

so the moulds cost will be on your account, of course the moulds belong to you

.