- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

6100 mm

-

Backgauge Travel (mm):

-

10 - 800 mm

-

Throat Depth (mm):

-

120 mm

-

Brand Name:

-

CNCColgar

-

Power (kW):

-

15 kW

-

Weight (KG):

-

6000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220/230/380/400V, 220V/380V/400V

-

Dimension(L*W*H):

-

6800x2200x2500 mm

-

Year:

-

2024

-

Marketing Type:

-

New Product 2024

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Customized

-

Shearing thickness:

-

12mm

-

Rated Power:

-

22kw

-

Shearing width:

-

6000mm

-

Operating system:

-

E21S

-

Shearing angle:

-

0.5-3.0

-

Weight:

-

25T

-

Certification:

-

CE

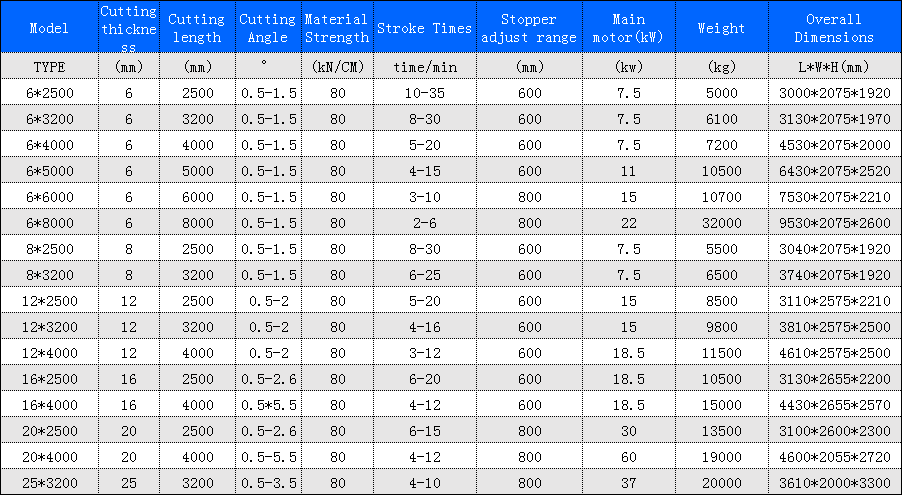

Quick Details

-

Max. Cutting Width (mm):

-

6000

-

Max. Cutting Thickness (mm):

-

4 mm

-

Shearing Angle:

-

0.5-1.5

-

Blade Length (mm):

-

6100 mm

-

Backgauge Travel (mm):

-

10 - 800 mm

-

Throat Depth (mm):

-

120 mm

-

Brand Name:

-

CNCColgar

-

Power (kW):

-

15 kW

-

Weight (KG):

-

6000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220/230/380/400V, 220V/380V/400V

-

Dimension(L*W*H):

-

6800x2200x2500 mm

-

Year:

-

2024

-

Marketing Type:

-

New Product 2024

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Customized

-

Shearing thickness:

-

12mm

-

Rated Power:

-

22kw

-

Shearing width:

-

6000mm

-

Operating system:

-

E21S

-

Shearing angle:

-

0.5-3.0

-

Weight:

-

25T

-

Certification:

-

CE

Products Description

|

Hydraulic Guillotine Shearing Machine Features:

|

|

|

|

|

||||

1, The machine is fitted with CNC controller special for shearing machines.

2, The position of rear stopper is displayed in real-time manner.

3, Multi-step programming function is available and the rear stopper is able for automatic operation and continuous positioning, to achieve an automatic adjustment for position of rear stopper.

4, It is provided with a counting function for shearing, to display the shearing numbers in a real-time manner, able for power-failure memory of position of rear stopper, procedures, and parameters.

5, Back gauge with precision ball screw and linear guide, to ensure the positioning precision, so that brings the higher accuracy of processing.

Details Images

Optional Systems

DAC360 System

E200PS System

E21S Dual Servo System

Lead time

15 days to 40 days

Payment Method

30% T/T in advance, the balance paid before shipping

irrevocable L/C at sight

irrevocable L/C at sight

FAQ&Contact us

Q:How to choose a shearing machine?

A:Please tell us the following information in detail:

- Material of plate:

-Max thickness:

-Max plate width:

-If possible: you can specify the model;

Q:Where is your factory? How can I get there?

A:You can fly to NanJing LuKou airport directly, we will pick you up in the airport. All our customers, both inland and abroad, warmly welcome to visit us!

Q:How do you ensure quality in the factory?

A:Quality culture.:We always attach great importance to quality control from the beginning to the end. Our factory has obtained ISO, CE certification.

Q:How can I pay?

A:You can pay by T/T, Western Union, MoneyGram, Paypal; 30% deposit; pay off the 70% balance before shipment.

Q: How long to produce?

A: Delivery time:15-35 days.

Hot Searches