- Product Details

- {{item.text}}

Quick Details

-

Power:

-

7.5KW

-

Weight (KG):

-

500

-

Raw material:

-

Coconut Shell

-

Product name:

-

Hardwood Charcoal Carbonization Stove

-

Usage:

-

Charcoal Maker

-

Name:

-

Wood Sawdust Continuous Carbonization Furnace

-

Keywords:

-

Charcoal Cabonization Furnace

-

Final product:

-

Charcoal Pieces

-

Color:

-

Customer's Request

-

Advantage:

-

Continuous Working Environment Friendly

-

Feature:

-

High Carbonizing Efficiency

-

Function:

-

Carbonizaton

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

songbai

-

Voltage:

-

220V

-

Power:

-

7.5KW

-

Weight (KG):

-

500

-

Raw material:

-

Coconut Shell

-

Product name:

-

Hardwood Charcoal Carbonization Stove

-

Usage:

-

Charcoal Maker

-

Name:

-

Wood Sawdust Continuous Carbonization Furnace

-

Keywords:

-

Charcoal Cabonization Furnace

-

Final product:

-

Charcoal Pieces

-

Color:

-

Customer's Request

-

Advantage:

-

Continuous Working Environment Friendly

-

Feature:

-

High Carbonizing Efficiency

-

Function:

-

Carbonizaton

Wood Airflow Hardwood Continuous Coconut Shell Biochar Charcoal Carbonization Stove Furnace Retort Kiln Biochar Making Machine

Product Description

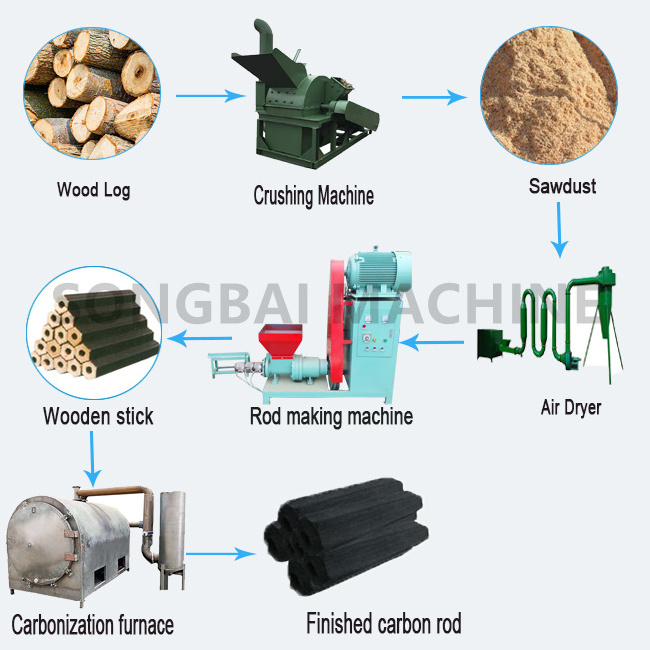

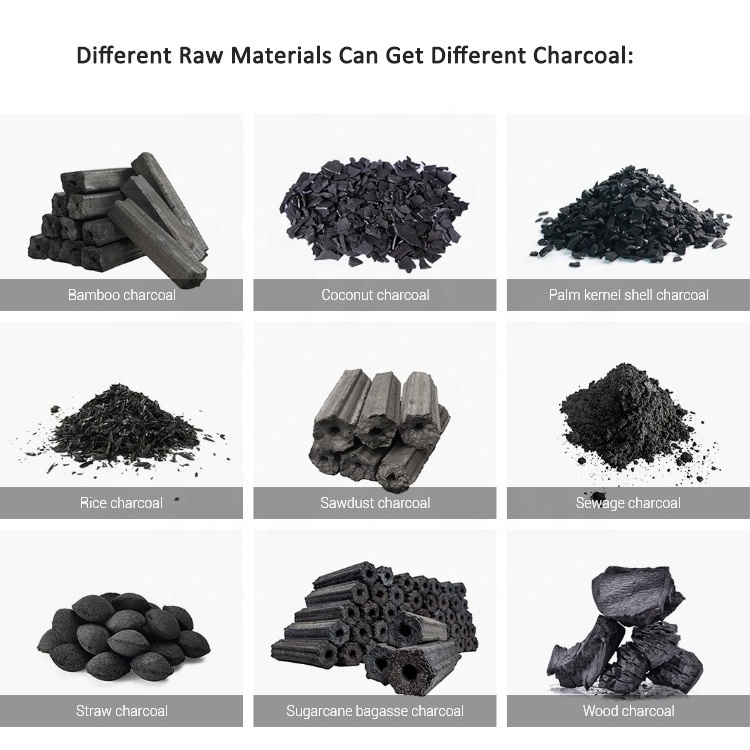

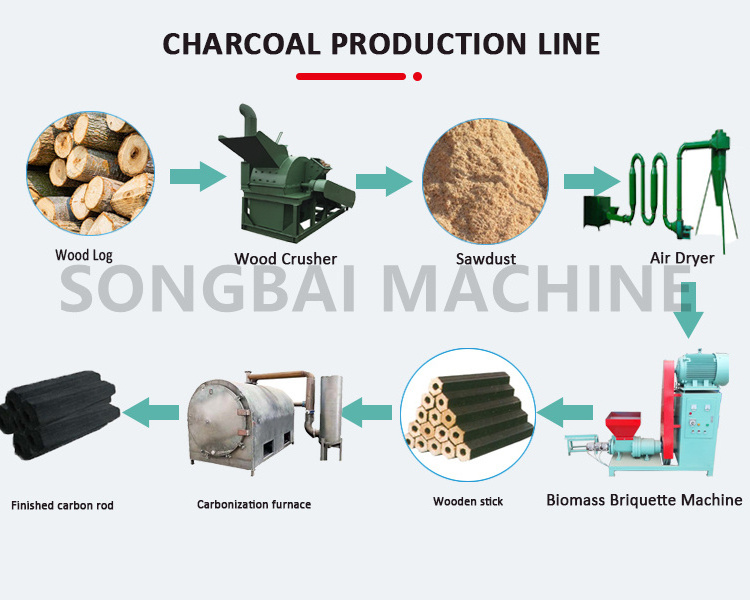

The Introduction Of Hardwood Coconut Shell Biochar Making Machine

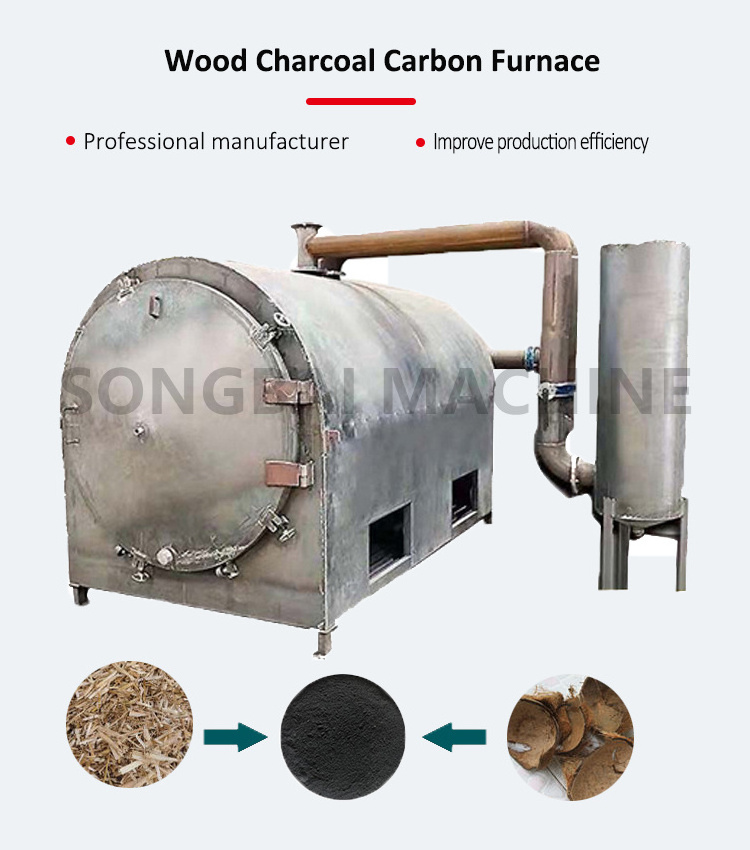

It adopts the advanced carbonized technology heat flow, carbonized rate increased significantly, The carbonized rate is 99%.And the operation is very convenient, good safety, high production efficiency, can save a lot of energy, good environmental protection performance. Shunt can also dry burning boiler flue gas and so on. Truly the charcoal, gas and oil range of equipment is currently the world's most advanced carbonization furnace.

|

Model

|

Inner size(m)

|

Dimension(m)

|

Weight(kg)

|

Carbonization cycle

|

Output

|

|

0815

|

0.8*1.5

|

1.8*1.1*1.3

|

400

|

8-10h

|

150-200kg

|

|

1215

|

1.2*1.5

|

1.9*1.5*1.8

|

650

|

10-12h

|

200-300kg

|

|

1515

|

1.5*1.5

|

1.9*1.8*2.3

|

1000

|

18-20h

|

400-500kg

|

|

1220

|

1.2 * 2

|

2.3*1.6*1.8

|

1200

|

18-24h

|

500-600kg

|

|

1330

|

1.3*3

|

3.3*1.8*2.3

|

2300

|

18-24h

|

700-800KG

|

|

1530

|

1.5*3

|

3.3*2*2.4

|

2800

|

18-24h

|

800-1000Kg

|

|

1545

|

1.5*4.5

|

4.7*1.9*2.3

|

3200

|

18-24h

|

1800-2000kg

|

|

2060

|

1.9 * 6

|

6.2*2.3*2.8

|

7000

|

18-24h

|

2800-3000 kg

|

Product Features

|

1.Carbonization furnace is the use of horizontal manufacturing process, carbonization furnace has a three-layer structure, and the middle of light insulation materials,It is possible to keep the temperature in the furnace at all times.

|

ZH-MC-420

|

ZH-MC- 500

|

ZH-MC-600

|

ZH-MC-800

|

ZH-MC-900

|

ZH-MC-1000

|

||||||

|

2.The door use packing seal, not into the air, Out of carbon than the conventional carbonization furnace is much higher.

|

380V/50HZ,3PH electricity, Customized according to client require

|

ZS-MC500

|

ZS-MC600

|

|

ZS-MC1000

|

|

||||||

|

3.The reason is called green carbonization furnace because the stick in the carbonization process will produce a lot of light yellow combustible gas. These gases through the carbonization furnace with there own pipes can make combustible gas diversion to the charring furnace combustion zone to the second fire heating. More environmentally friendly and saving fuel.

|

11KW

|

18.5KW

|

22KW

|

37KW

|

55KW

|

75KW

|

||||||

|

4.Carbonization furnace excess gas can be used to dry the sawdust or to burn the boiler.

|

15HP

|

25HP

|

32HP

|

4102 diesel engine

|

4105 diesel engine|

|

4105 diesel engine

|

||||||

|

5.Carbonization furnace to end charcoal cooling time is shorter, we use the inter layer of the gap between the unit water cooling carbonization furnace natural cooling, more efficient

|

300-1000kg/h

|

800-1500kg/h

|

1000-2000kg/h

|

1500-2500kg/h

|

2000-3000kg/h

|

3000-4000kg/h

|

||||||

Machine Details

It adopts the advanced carbonized technology heat flow, carbonized rate increased significantly, The carbonized rate is 99%.And the operation is very convenient, good safety, high production efficiency, can save a lot of energy, good environmental protection performance. Shunt can also dry burning boiler flue gas and so on. Truly the charcoal, gas and oil range of equipment is currently the world's most advanced carbonization furnace.

Product Application

Factory Real Shot

Packing & Delivery

Carbonization furnace packing and shipping

Packed in standard wooden case

Shipping by sea

Hot Searches