- Product Details

- {{item.text}}

Quick Details

-

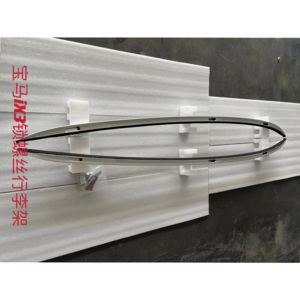

Name:

-

Die Casting Parts

-

Material:

-

Aluminum alloy:ADC12, ADC10, A360, A380, A356, 6061, 6063

-

Process:

-

Die Casting + Machining

-

Service:

-

OEM ODM Customised

-

Standard:

-

GB ASTM AISI DIN BS

-

Casting Tolerance:

-

CT4-7

-

Heat treatment:

-

T5-T6

-

Certification:

-

ISO9001:2015

-

MOQ:

-

1 Pcs

-

Quality Control:

-

Professional Inspection

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

SPT

-

Model Number:

-

milling machining aluminum extrusion manufactures

-

Name:

-

Die Casting Parts

-

Material:

-

Aluminum alloy:ADC12, ADC10, A360, A380, A356, 6061, 6063

-

Process:

-

Die Casting + Machining

-

Service:

-

OEM ODM Customised

-

Standard:

-

GB ASTM AISI DIN BS

-

Casting Tolerance:

-

CT4-7

-

Heat treatment:

-

T5-T6

-

Certification:

-

ISO9001:2015

-

MOQ:

-

1 Pcs

-

Quality Control:

-

Professional Inspection

SPECIFICATION

|

Manufacturing Method

|

Die Casting Services

|

|

|

|

|||

|

Material Standard

|

GB, ANSI, BS, DIN, JIS, ASTM, ASME, AISI, etc Aluminum alloy: ISO3522-84, ASTMB85-96, JISH5302:2000, EN1706:1998 Aluminum alloy:

ADC12, ADC10, A360, A380, A356, 6061, 6063 2.Magnesium alloy: ISO/DIS16220-1999, ASTMB93/B93M-98, EN1754-1997 Magnesium alloy: AZ91D, AM60B, 3.Zinc alloy: ISO301-1981,ASTMB327-98, JISH2021:1999, EN12844:1998 Zinc alloy: ZA3#,ZA5#,ZA8# |

|

|

|

|||

|

Tolerance

|

±0.02mm

|

|

|

|

|||

|

General Casting Tolerance

|

ISO 8062 , Customized

|

|

|

|

|||

|

Design Software

|

UG, Pro-E, Inventor

|

|

|

|

|||

|

Mould Manufacturing

|

Yes

|

|

|

|

|||

|

Casting Stimulation

|

UG, Pro-E, Inventor

|

|

|

|

|||

|

Quality Standard

|

ISO9001

|

|

|

|

|||

|

Ultimate machining tolerance

|

0.005mm

|

|

|

|

|||

|

Machining Roughness

|

Ra0.8-Ra3.2 according to customer requirement

|

|

|

|

|||

|

Heat Treatment

|

Normalization , annealing, quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching.

|

|

|

|

|||

|

Surface Treatment

|

Shot, sand blast, polishing, Surface passivation, Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat

coating, Finish Painting,Anodization,etc |

|

|

|

|||

Q1. Are you a factory or trade company?

A: We are a factory with over 20 years in casting,forging ,fabrication and machining. We service customers in various fields such as mining, agriculture, car parts ,etc.

Q2. Where is your factory?

A: Our factory locates in Dandong City,Liaoning Province, where close to Dalian port within 1 hr drive.

Q3. How to quote?

A: Received the sample or drawing, then we will make the quotation.

Q4. How about the MOQ?

A: Depend on the weight and material, if it is our daily melting material, there is no MOQ.

Q5. Payment terms

A: Mold costs: 50% deposit,, balance after sample approval

Mass production: 50% deposit, balance upon B/L available.

A: We are a factory with over 20 years in casting,forging ,fabrication and machining. We service customers in various fields such as mining, agriculture, car parts ,etc.

Q2. Where is your factory?

A: Our factory locates in Dandong City,Liaoning Province, where close to Dalian port within 1 hr drive.

Q3. How to quote?

A: Received the sample or drawing, then we will make the quotation.

Q4. How about the MOQ?

A: Depend on the weight and material, if it is our daily melting material, there is no MOQ.

Q5. Payment terms

A: Mold costs: 50% deposit,, balance after sample approval

Mass production: 50% deposit, balance upon B/L available.

Q6.Delivery time

A: Normally 25-40 days;

A: Standard or customized will both be available.

Q7. How about the packing?

A: Standard or customized will both be available.We will consider the transfer at warehouse and long time anti rust during on the sea.

Q8. How can I get more information?

A:If you need more information, you can send email to davidlee@sharpentech.cn, if you need any instant answer, please call 0086-133-04054120,thanks.

A: Normally 25-40 days;

A: Standard or customized will both be available.

Q7. How about the packing?

A: Standard or customized will both be available.We will consider the transfer at warehouse and long time anti rust during on the sea.

Q8. How can I get more information?

A:If you need more information, you can send email to davidlee@sharpentech.cn, if you need any instant answer, please call 0086-133-04054120,thanks.

Hot Searches