- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

SMA to IPEX

-

Product Name:

-

RF Cable Assembly

-

Impedance:

-

50 Ohm / 75 Ohm

-

Gender:

-

Male / Female

-

Mounting Type:

-

PCB Mount / Panel Mount / Crimp Type

-

Mounting Feature:

-

Rear Bulkhead / Front Bulkhead / 4 Hole Flange

-

Orientation:

-

Straight / Right Angle

-

Function:

-

Waterproof / Dustproof / None

-

Cable Type:

-

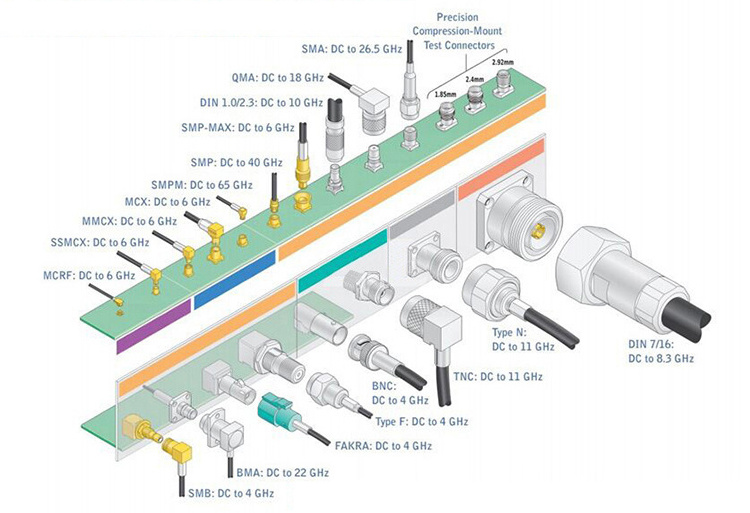

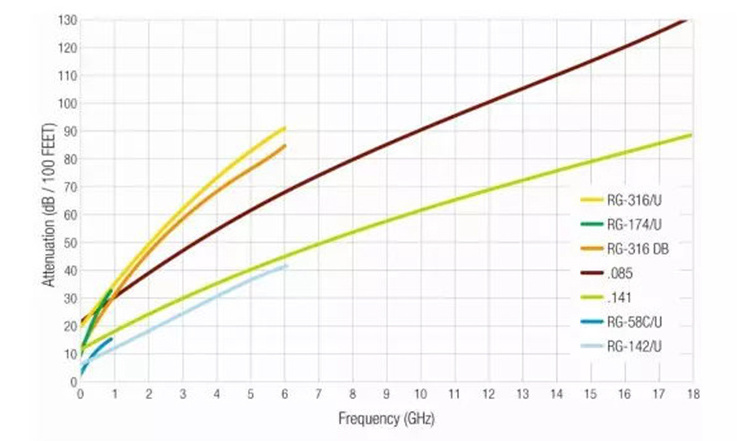

RG58/142/174/178/223/316/401,LMR195/200/400,1.13/1.37

-

Application2:

-

Aerospace Industries / Medical / Wireless Applications

Quick Details

-

Application:

-

RF

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DOSIN

-

Model Number:

-

SMA to IPEX

-

Product Name:

-

RF Cable Assembly

-

Impedance:

-

50 Ohm / 75 Ohm

-

Gender:

-

Male / Female

-

Mounting Type:

-

PCB Mount / Panel Mount / Crimp Type

-

Mounting Feature:

-

Rear Bulkhead / Front Bulkhead / 4 Hole Flange

-

Orientation:

-

Straight / Right Angle

-

Function:

-

Waterproof / Dustproof / None

-

Cable Type:

-

RG58/142/174/178/223/316/401,LMR195/200/400,1.13/1.37

-

Application2:

-

Aerospace Industries / Medical / Wireless Applications

FAQ Cases:

How to confirm RF cable assembly

B: I need a RF Cable Assembly

S:

Pls advise the connector and gender on both end?

B:

S

MA Female on one end and N Male on the other end

S:

How about the cable, what is the length and guage?

B

:

RG58 cable, 1M

S:

Ok, how many pcs will be needed?

B:

1000pcs

B: S MA Female on one end and N Male on the other end

S: How about the cable, what is the length and guage?

B : RG58 cable, 1M

S: Ok, how many pcs will be needed?

B: 1000pcs

RF Cable Assemblies

75 ohm cable assemblies can be made with the following 75 ohms connectors such as BNC , F , N, SMB , SMA , TNC and mini SMB .

Product Feature

• Quick connect/disconnect snap-on mating reduces installation time;

Stamping Workshop

Insert Metal Plate between the top and bottom mold, and then apply pressure to cut the plate. Ideal for mass production as high production capacity with only one die mold.

Die casting Workshop

Forcing the molten metal under high pressure into a mold cavity. In DOSIN, this workshop is main for die casting moulding to make Zinc Alloy or Aluminium Alloy parts.

Injection Moulding Workshop

Injection moulding requires to transfer the polymeric material in powder or granule form from a feed hopper to a heated barrel. And then the plastic melted and injected into a mould. This process is automated, so the production capacity is high.

Lathe Turning

Lathe is used to remove unwanted material from a cylindrical workpieces by machine tool. We used lathe to produce copper parts and insulators (like Teflon). No mould required for this process. The production capactity limited by products' structure and quantity of machine.

We have been owning a factory since established in 2005. The factory keeps developing as our business grows larger.

Normally our MOQ is 200pcs. Small order is also available.

3. What about the lead time for production?

3-5 working days for samples, 10-15 working days for bulk order.

4. How is your product quality?

5. What's the warranty?

One year, 12 months.