Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS-mach

-

Voltage:

-

380V/220V 3P

-

Dimension(L*W*H):

-

18M*2.6M*2.8M

-

Power (kW):

-

250

-

Weight:

-

8500 KG

-

Name:

-

Plastic Sheet Extrusion Machine

-

Model:

-

GS1400mm

-

Adaption Material:

-

PLA & PET & PP

-

Sheet Thickness:

-

0.4mm-1.6mm+-2%

-

Control:

-

PLC+Touch Screen

-

Installation Capacity:

-

232kw

-

Description:

-

pet sheet extrusion line

-

After-sales Service Provided:

-

Field Installation maintenance and repair service

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

44:1

-

Screw Speed (rpm):

-

500 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS-mach

-

Voltage:

-

380V/220V 3P

-

Dimension(L*W*H):

-

18M*2.6M*2.8M

-

Power (kW):

-

250

-

Weight:

-

8500 KG

-

Name:

-

Plastic Sheet Extrusion Machine

-

Model:

-

GS1400mm

-

Adaption Material:

-

PLA & PET & PP

-

Sheet Thickness:

-

0.4mm-1.6mm+-2%

-

Control:

-

PLC+Touch Screen

-

Installation Capacity:

-

232kw

-

Description:

-

pet sheet extrusion line

-

After-sales Service Provided:

-

Field Installation maintenance and repair service

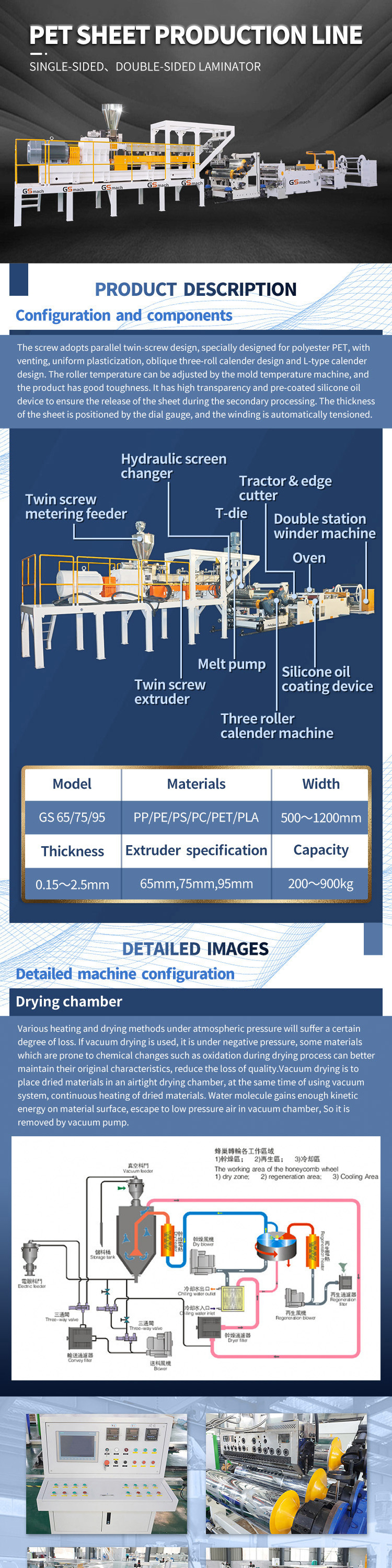

PET/PLA/PP/PE/PVC/PC Sheet extrusion line

Overall View

PET/PLA/PP/PE/PVC/PC Sheet extrusion line

In PET/PLA/PP/PE/PVC/PC sheet/film production, we prefer straightforward and efficient operations. The traditional pre-drying procedure has been

completely removed from the entire process. Whatever the combination, 100% PET/PLA/PP/PE/PVC/PC pellets or flakes or virgin, or a mixture of them,

our systems can easily handle it.

Advantages

1- The production of high quality PET flakes using 100% bottle flakes.

In PET/PLA/PP/PE/PVC/PC sheet/film production, we prefer straightforward and efficient operations. The traditional pre-drying procedure has been

completely removed from the entire process. Whatever the combination, 100% PET/PLA/PP/PE/PVC/PC pellets or flakes or virgin, or a mixture of them,

our systems can easily handle it.

Advantages

2- The GSmach system is characterised by a decontamination/dehumidification process (about one hour's time) that completely

extracts the volatile components still present in the bottle flakes, resulting in a flake quality superior to any non-dry

co-transfer system.

3- Production of perfect, non-fragile flakes that do not face any drop in IV (Intrinsic Viscosity) during production, with no

restrictions on thickness. Tested with a sheet thickness of 1.5 mm.

4- Possibility to reduce the thickness of thermoformed articles.

5- There is no limit to the amount of recycled material generated during the thermoforming process. The zero drop in viscosity

makes it possible to reprocess the thermoformed backbone of the PET sheet produced on the sheet extruder line, creating an endless

production process starting from the first sheet produced on the machine.

6- Effective energy saving technology with very low energy consumption.

Details Images

|

Technical Specifications of sheet Extruder:

|

|

|

|

|

||||

|

Type

|

materials

|

Width

|

Output(kg/h)

|

Thickness

(mm)

|

||||

|

GS65

|

PP/PE/PS/PC/PET/PLA/PVC

|

500-1200mm

|

200-400

|

0.15-2.5

|

||||

|

GS75

|

PP/PE/PS/PC/PET/PLA/PVC

|

500-1200mm

|

400-600

|

0.15-2.5

|

||||

|

GS95

|

PP/PE/PS/PC/PET/PLA/PVC

|

500-1200mm

|

600-900

|

0.15-2.5

|

||||

Flow Chart Description

Feeder → transit bin → loss-in-weight feeding → twin-screw mixing → filter → gear pump → distributor → T-die → three-roll calendar

→ cooling stack and trimming → thickness tester → corona treatment → silicon/antistatic coating and drier → protective film

coating → traction → automatic winder with accumulator

Feeder → transit bin → loss-in-weight feeding → twin-screw mixing → filter → gear pump → distributor → T-die → three-roll calendar

→ cooling stack and trimming → thickness tester → corona treatment → silicon/antistatic coating and drier → protective film

coating → traction → automatic winder with accumulator

Application

PP/PE/PS/PC/PET/PLA/PVC Film Sheet

Hot Searches