- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Place of Origin:

-

China

-

Brand Name:

-

HENTO

-

Dimension(L*W*H):

-

1800*80*1800mm

-

Weight:

-

400 KG

-

Certification:

-

CE

-

Product name:

-

Wrapping Machines Luggage Airport

-

Function:

-

Packing Luggage

-

Turntable speed:

-

1-15 laps / minute

-

Bearing capacity:

-

110KG

-

Machine weight:

-

400KG

Quick Details

-

Packaging Type:

-

Film, Luggage

-

Packaging Material:

-

Film

-

Driven Type:

-

Electric

-

Voltage:

-

220V

-

Place of Origin:

-

China

-

Brand Name:

-

HENTO

-

Dimension(L*W*H):

-

1800*80*1800mm

-

Weight:

-

400 KG

-

Certification:

-

CE

-

Product name:

-

Wrapping Machines Luggage Airport

-

Function:

-

Packing Luggage

-

Turntable speed:

-

1-15 laps / minute

-

Bearing capacity:

-

110KG

-

Machine weight:

-

400KG

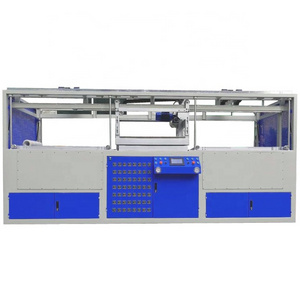

High Speed Suitcase Luggage Making Machine Wrapping Machines Luggage Airport

1, Overall appearance and introduction

This equipment is a pre stretched film wrapping machine specifically designed for packaging small luggage items. It uses wrapping film to wrap and secure cargo pallets. This product is suitable for packaging manual, simple, and lightweight materials. It is widely used in non mass continuous packaging places such as shopping malls, airports, stations, offices, postal services, logistics companies, etc., replacing manual wrapping, saving costs and improving production efficiency, It can also prevent damage to the goods during transportation, and play a dustproof, moisture-proof, and cleaning role.

This product has a simple design, compact structure, beautiful appearance, and advanced technology. It has passed the European Safety CE certification and adopts strict machine operation safety protection measures. At the same time, in order to facilitate the use of this device by non professionals, measures have been taken to reduce the complexity of the operation panel, making the operation of the device simple, easy to understand, and convenient.

Characteristic:

1.Small size, flexible mobility, suitable for any location, replacing manual winding. Especially the packaging advantages of small products are more obvious. Especially suitable for various types of luggage

packaging.

2. The control system is controlled by a dedicated PLC system to drive the frequency converter motor and control the mechanical transmission mechanism to achieve stepless speed regulation. The system is stable and reliable, and the equipment is easy to use and maintain.

3. It can automatically detect the height of the outer packaging material, the number of device packaging circles, etc. Different packaging modes can be preset to meet the different packaging requirements of different types of packaging materials.

4. Film pulling mechanism: Pre pulling type (with a film pre stretching ratio of up to 1:3) saves materials and produces good packaging effects.

*Additional Remarks

In case of the machine upgrade, the structure may be a little different, please take the actual machine as the standard.

|

Model |

HT-XL200 |

|

Power Supply |

AC220V 50HZ/60HZ |

|

Machine dimensions |

1650*650*1500 |

|

Rotary table motor |

0.37KW motor |

|

Lifting motor |

0.20KW motor |

|

Packaging film stretching motor |

0.20KW motor |

|

Maximum packaging size |

500*600*1000MM |

|

Maximum packaging weight |

50 /100/200kg(customized) |

|

rotary speed |

0~20R/min |

|

Maximum drum diameter of the film |

250mm |

|

Inner drum diameter |

75mm |

|

Film cylinder height |

500mm |

|

Machine weight |

260 -400 KG |

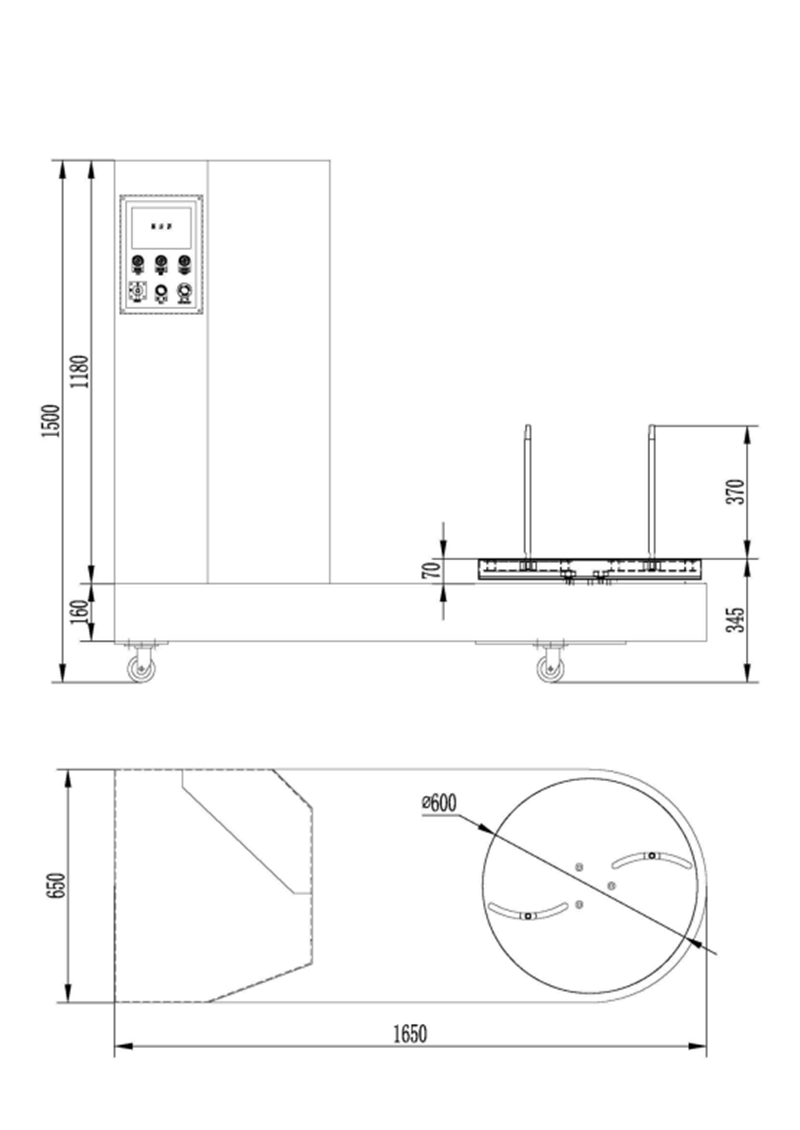

Outline drawing:

If you need further information, please contact us freely, we will do our best to cooperate with you.