Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FULLWIN

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

depend on design

-

Power (kW):

-

86

-

Weight:

-

4000 KG

-

Name:

-

Extrusion Machine

-

Raw material:

-

PVC

-

Usage:

-

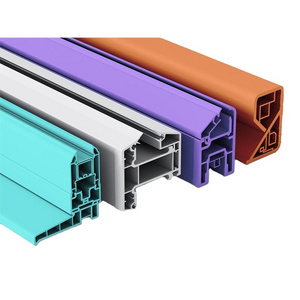

Profile

-

Color:

-

Customer Choice

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

-

Capacity:

-

200kg/h

-

Used for:

-

cable

-

Screw type:

-

Twin Screw

-

product size:

-

customized

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw diameter (mm):

-

51

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FULLWIN

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

depend on design

-

Power (kW):

-

86

-

Weight:

-

4000 KG

-

Name:

-

Extrusion Machine

-

Raw material:

-

PVC

-

Usage:

-

Profile

-

Color:

-

Customer Choice

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

-

Capacity:

-

200kg/h

-

Used for:

-

cable

-

Screw type:

-

Twin Screw

-

product size:

-

customized

Product Description

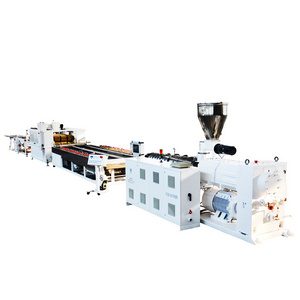

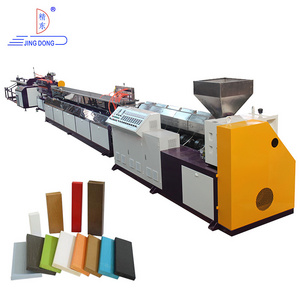

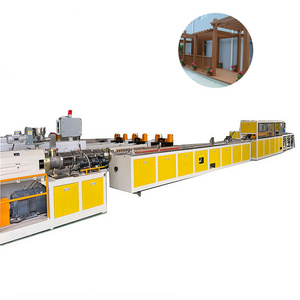

WPC Wood Plastic Composite Flooring Profile Making Machine

1.Process flow:

a.Get your ingredients ready and mix them.

b.The uniformly mixed materials are put into the hopper of the extruder through the automatic screw feeder.

c.The material put into the hopper of the extruder is melted and plasticized by the extruder and extruded into the vacuum setting device through the die.

d.The material extruded through the extruder die is sent to the vacuum setting device, cooled and shaped by circulating cooling water.

e.The cooled and shaped wood-plastic panels are pulled out by a tractor and sent to the cutting machine.

2.Practical application:

Wood-plastic floor panels can avoid the disadvantages of traditional wood decoration materials, and there will be no problems such as cracking and deformation during use. Moreover, the wood-plastic board is also flame-retardant, so it is very suitable for installation indoors and outdoors. Wood-plastic floor panels can not only make up for the disadvantages of traditional materials,but also prolong the service life and reduce the application cost of the panels.

|

NO.

|

Description

|

Qty

|

|

1

|

65/132 Double Screw Extruder with auto feeder

|

1 set

|

|

2

|

Die head and Extrusion mould

|

1 set

|

|

3

|

Vacuum calibrating platform

|

1 set

|

|

4

|

Standard Traction Machine

|

1 set

|

|

5

|

Standard Cutting Machine

|

1 set

|

|

6

|

Automatic Unloading Platform

|

1 set

|

Extruder machine

Length and diameter ratio:22:1

Auto screw loader

Screw and barrel material:38CrMoAIA

Auto screw loader

Screw and barrel material:38CrMoAIA

Die head

material: stainless steel

design as customer sample

Double screw extruder machine with co-extrusion and online embossing

Haul off and cutting machine

Final products

Contact us

About us

After sales service

- After all machines are delivered to customer's factory; Buyer is responsible for all preparation work, e.g. electricity supply,

water supply, labors and cranes, etc.

- Fullwin will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory.

- The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for each engineer.

- Engineer will give free training lessons to labors in buyer's factory.

- If buyer doesn't request installation and commissioning by Seller's engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by buyer.

water supply, labors and cranes, etc.

- Fullwin will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory.

- The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for each engineer.

- Engineer will give free training lessons to labors in buyer's factory.

- If buyer doesn't request installation and commissioning by Seller's engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by buyer.

FAQ

Q:Are you machinery factory or trading company?

A:We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

Q: How can we visit your company and machines?

A : Our factory is in Jiaozhou Town, Qingdao City, Shandong Province, China. About 1 hours from Qingdao International Ariport.

Q:What`s the payment method?

A:We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

Q: How can we visit your company and machines?

A : Our factory is in Jiaozhou Town, Qingdao City, Shandong Province, China. About 1 hours from Qingdao International Ariport.

Q:What`s the payment method?

A: T/T, L/C,Western Union,etc

Hot Searches