- Product Details

- {{item.text}}

Quick Details

-

Structure:

-

Chain/Belt/Roller Conveyor

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

BOTTLING

-

Voltage:

-

Customized, Customized

-

Weight (KG):

-

100 kg

-

Name:

-

Conveyor

-

Materials of belt:

-

PVC/POM.AC/SUS304/Plastic steel

-

Width:

-

63.5mm-304.8mm

-

Height:

-

Adjustable

-

Power of motor:

-

0.37/0.55/0.75KW

-

Max conveying length:

-

12m(pom)/15m (SUS304)

-

Max speed:

-

80m/min

-

Operating temperature range:

-

-40℃ to 90℃

-

Usage:

-

Material Transmission

Quick Details

-

Power:

-

0.37KW

-

Warranty:

-

1 Year

-

Width or Diameter:

-

63.5mm-304.8mm

-

Structure:

-

Chain/Belt/Roller Conveyor

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

BOTTLING

-

Voltage:

-

Customized, Customized

-

Weight (KG):

-

100 kg

-

Name:

-

Conveyor

-

Materials of belt:

-

PVC/POM.AC/SUS304/Plastic steel

-

Width:

-

63.5mm-304.8mm

-

Height:

-

Adjustable

-

Power of motor:

-

0.37/0.55/0.75KW

-

Max conveying length:

-

12m(pom)/15m (SUS304)

-

Max speed:

-

80m/min

-

Operating temperature range:

-

-40℃ to 90℃

-

Usage:

-

Material Transmission

Products Description

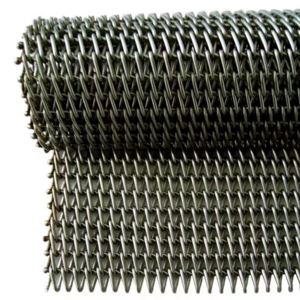

Straight

plastic steel chain conveyor:

This kind of bottle Linear plastic steel chain plate conveyor is used in the beverage production lines to other transferring lines. It is used to convey PET bottles, glass bottles, pop-top cans and other containers like tetra pack etc,. The length and width as well as material of this conveyor can be made according to clients' requirements. It is widely used for automatic transmission, distribution and packaging in food, tin cans, drugs, beverage, cosmetics, cleaning products, paper products, spices, dairy and tobacco.

90° / 180°

curved

chain conveyor:

Curved conveying can change the direction. We will carry out professional design according to the customer's actual workshop size, and rationally arrange the position of curved conveyor to save the space occupied by the production line.

Straight

SUS304

chain belt conveyor:

The stainless steel chain plate conveys water-proof, anti-rust, and runs smoothly. High temperature resistance, corrosion resistance, heavy load and long life. It is mainly used for conveying machinery in bottling lines, packaging lines, washing lines, drying lines, and spraying lines. It is a high-demand conveyor belt product.

|

Chain plate Parameter:

|

|

|

|

Max speed:

|

80m/min V-lubricant, 50m/min V-dry

|

|

|

Spindle:

|

Stainless steel

|

|

|

Operating temperature range:

|

-40℃ to 90℃

|

|

|

Packing:

|

10ft=3.048m/box 1metel=26pcs

|

|

|

Chain plate material

|

Pom.AC/Stainless steel

|

|

|

Max conveying length:

|

12m(pom)/15m (SUS304)

|

|

|

Max loading tension:

|

Liner plastic steel chain plate:1100N

Liner SUS304 chain plate:2250N Turn plastic steel chain plate:2100N Turn SUS304 chain plate:2250N |

|

|

Characters:

|

low friction

|

|

|

Back curved radius:

|

50mm /150mm (US304)

|

|

|

Motor parameter:

|

|

|

|

|

|

|

|

|||||||

|

Power

|

HP

|

Volt

|

hertz

|

ampere

|

EFF

|

r/min

|

cosφ

|

|||||||

|

0.37KW

|

0.5

|

380V/220V

|

50HZ

|

1.12A/1.96A

|

67%

|

1400

|

0.75

|

|||||||

|

0.75KW

|

1

|

380V/220V

|

50HZ

|

2.03A/3.52A

|

73%

|

1400

|

0.76

|

|||||||

|

0.55KW

|

0.75

|

380V/220V

|

50HZ

|

1.64A/2.85A

|

70%

|

1400

|

0.75

|

|||||||

Straight

PVC Belt Conveyor

:

Belt conveyor also known as belt conveyor line, belt assembly line. The continuous or intermittent movement of conveyor belt is used to transport heavy and light goods, which can not only transport various bulk materials, but also various cartons, packaging bags and other small single weight goods. It is suitable for food, electronics, chemistry, printing and other industries.

Characteristics:

Because of its smooth transportation, there is no relative movement between the material and the conveyor belt, which can avoid the damage to the conveying materials. Compared with other conveyors, the noise is smaller, and it is suitable for quiet working environment. Because of its simple structure, easy maintenance, low energy consumption and low cost, it can not only be used for the transportation of ordinary materials, but also meet the transportation of materials with special requirements such as oil resistance, corrosion resistance and anti-static. The special food grade conveyor belt can meet the requirements of food, pharmaceutical and daily chemical industries.

Parameter:

Main frame material:SUS201

Material of base plate:Galvanized material

Maximum temperature of tolerance:79℃

Maximum conveying speed: 20m/min

Max conveying length: 10m

Max loading tension: 490N

Characters: low friction

PVC Belt thickness:2mm

Packaging information: Wrapping film packaging

|

Power

|

HP

|

Volt

|

Hertz

|

Ampere

|

EFF

|

r/min

|

cosφ

|

|

0.37KW

|

0.5

|

380V/220V

|

50HZ

|

1.12A/1.96A

|

67%

|

1400

|

0.75

|

Air conveyor:

This conveyor is used for connecting with bottle blow molding machine and

filling machine to feed the plastic bottles automatically

or you can manually hang the bottles on the air conveyor, the air blower will blow the bottles to the filling machine.

Mechanical part:

Body material: SUS304 for air tunnel, legs , side guide fixing, blower holder

Neck holding stripes: stainless steel or nylon

Body side guides: Aluminium alloy based nylon stick

Characters:

1, Air block passage-bottle neck protection

2, Air filter blower to make sure clean air blowing

3, Easy bottle neck-width change

4, Bottle neck-body protection material application

Roller conveyor:

The roller conveyor also named gravity conveyor, gravity roller conveyor, usually adopts the steel conveyor rollers to installed within a certain frame to transfer work piece on the surface.

Roller conveyors are a series of rollers supported within a frame where objects can be moved either manually, by gravity, or by power.

There is a wide range of ways roller conveyors can be used and modified for different uses including transporting boxes, cardboard boxes, crates, pallets, plastic totes, polybags, slave boards, and trays.

A roller conveyor system can be configured to work with a range of ancillary equipment including bends, gates, and turntables.

Roller conveyors are normally used in environments such as warehouses or manufacturing facilities due to the nature of transporting goods.

Using a roller conveyor can add versatility to the type of transfers, diverters, and stops that can be used as part of a conveyor system or automation system. You can get roller conveyors in stainless steel.

Features:

1. Economic and practical, cost-effective;

2. Reliable operation, low noise and safety;

3. Large load capability;

4. Lightweight design, fast installation;

|

Power type

|

Manual, non power / Powered

|

|

Roller material

|

SUS304

|

|

Roller diameter

|

32mm

|

|

Thickness

|

1.2mm

|

|

Roller length

|

320mm

|

|

Roller separation distance

|

40mm

|

|

Loading capacity

|

100kg/m

|

|

Application

|

Low height and heavy duty field

|

Flexible telescopic

expandable

roller conveyor

:

1. It occupies a small area and can scale freely. The ratio of the longest to the shortest unit is 3 times.

2. The direction is easy to change, and the conveying direction can be changed flexibly, up to 180 degrees at the maximum.

3. The conveying carrier is diverse, the conveying carrier can be a drum or a roller.

4. The caster device is easy to move, the lifting device can flexibly adjust the unit or the overall height, and it can also be adjusted to an inclined surface.

5. Equipped with electric roller or micro motor drive, it can be more convenient and labor-saving.

Application: It is widely used in the transportation of finished product packaging boxes and turnover boxes in various industries.

Application advantages: low cost, simple structure, convenient maintenance, reliable operation, strong conveying capacity.

The telescopic roller conveyor adopts self-developed aluminum alloy material as the frame, with strong load-bearing capacity (300KG/M), and imported casters. The equipment is beautiful and durable. It can also be made according to customer requirements.

company profile

ZhangJiaGang City BOTTLING MACHINERY Co.,Ltd. is located in Zhangjiagang city which is core of beverage machinery producer collection in China. Integrated the industry advantages and its own development in R&D, production, sales, after sales service,

BOTTLING MACHINERY is ready to serve more and more customers with our full range products and best service.BOTTLING MACHINERY is very critical in the choice of raw materials and spare parts. Korea 304 /316 stainless steel plate, ABB, SEW motors, Siemens, Mitsubishi, OMRON electrical control components, FESTO CAMOZZ the control valve, as well as international precision machining center for the fine quality of the machine foundation.

We are the supplier who can design and manufacture for all kinds beverage production plant (pure drinking water, mineral water,carbonated drinks, juice, tea and beer, etc.)

BOTTLING MACHINERY is ready to serve more and more customers with our full range products and best service.BOTTLING MACHINERY is very critical in the choice of raw materials and spare parts. Korea 304 /316 stainless steel plate, ABB, SEW motors, Siemens, Mitsubishi, OMRON electrical control components, FESTO CAMOZZ the control valve, as well as international precision machining center for the fine quality of the machine foundation.

We are the supplier who can design and manufacture for all kinds beverage production plant (pure drinking water, mineral water,carbonated drinks, juice, tea and beer, etc.)

Customer's service:

1. ZhangJiaGang City BOTTLING MACHINERY Co.,Ltd. can provide turn-key project for you, we can design the beverage factory plan according to your idea.

2. BOTTLING MACHINERY company have professional design team, our engineers can draw bottle samples and flow chart of workshop for you .

3. BOTTLING MACHINERY company can give you the best quotation for all kinds of beverage production, as long as you tell us which kind of drink you want to produce, what is your capacity(how many bottles one hour) what is you bottle material, pet or glass bottle or can, etc.

After service:

1. We send our engineers to your factory to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the goods shipping to you:

a. Machines layout drawing.

b. Electricity diagram.

c. Machine certificate.

d. General manual book/maintenance book.

3. After one year guarantee, the seller provides payable spare parts and technician's VISITING maintenance service.

1. ZhangJiaGang City BOTTLING MACHINERY Co.,Ltd. can provide turn-key project for you, we can design the beverage factory plan according to your idea.

2. BOTTLING MACHINERY company have professional design team, our engineers can draw bottle samples and flow chart of workshop for you .

3. BOTTLING MACHINERY company can give you the best quotation for all kinds of beverage production, as long as you tell us which kind of drink you want to produce, what is your capacity(how many bottles one hour) what is you bottle material, pet or glass bottle or can, etc.

After service:

1. We send our engineers to your factory to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the goods shipping to you:

a. Machines layout drawing.

b. Electricity diagram.

c. Machine certificate.

d. General manual book/maintenance book.

3. After one year guarantee, the seller provides payable spare parts and technician's VISITING maintenance service.

Packing&Delivery of BOTTLING

1. Our machines are packed by wooden case.

2. The delivery date of this machine is within 10-25 days after payment.

FAQ

Q:Are you a manufacturer or trade company?

A:We are a manufacturer in beverage bottling machine field more than 10 years, located at Leyu town, ZhangJiaGang, 2 hours from Shanghai, We will pick you up from Shanghai

Pudong Airport

to visit our factory.

Q:Do you have any certification?

A:SGS,ISO,CE etc

Q:What about the delivery time?

A:Usually 20-30 Working days for most kinds of machines

Q:What about the machine’s capacity?

A:1000 - 20000 bottles

per hour

based on 500ml bottle.

Q:The after-sale service

A:12 months warranty.

We can solve basic questions by telephone, email, whatsapp, wechat and video call.

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

Operating manuals will be sent with machines or by email.

We also have overseas service center

Q:If our bottle size changes, can we just do some adjustment on machine according to our new bottle?

A:Yes. Maybe you just need some spare little parts to change.

Q: If I want to purchase the machine, what information do I need to tell you?

A:a. What kind beverage you want to produce?

b. bottle volume? 250ml, 330ml, 500ml, 750ml, etc.?

c. Producing capacity requirement? How many bottles per hour?

d.Raw water analysis report .

e.Voltage and altitude.

Q:What kinds of product you supply?

A: Drink water/juice/carbonated drink filling line for bottle or can.

5 gallon/20L bottle water filling line.

Water treatment system.

Bottle blowing molding machine.

After packing system(label machine, PE film shrink packing machine, carton machine)

Sachet water packing line

Contact us

MS YOLANDA

5 years’ experience in foreign trade sales

Major in International business at

Yantai University

Whatsapp/Wechat: +8615190564896

Email:

yolanda@zjgbottlingmachinery.com

MR PHIL LANE

8 years’ experience in foreign trade sale

Major

Architecture, skilled CAD drawing, physical structure

China College English Test-6

Whatsapp/Wechat: +8615737466736

EMail: admin@zjgbottlingmachinery.com

EMail: admin@zjgbottlingmachinery.com

MR

ANDY

6 years in foreign trade sales

Major in mechanical engineering at university

Proficiency in photoshop drawing

Whatsapp/Wechat: +8613306249269

Email: sales1@zjgbottlingmachinery.com

Email: sales1@zjgbottlingmachinery.com

Hot Searches