1. Under the same working conditions, the decomposition rate of ozone with the same quality catalyst is higher and more stablethan that of the same kind of products .

2. Ozone removal process without the need to provide any additional chemicals .

3. High efficient catalytic decomposition of ozone at room temperature to produce oxygen to meet the requirements of safety and economy .

4. The material is simple and convenient to use, has long service life, and the purification efficiency of other catalysts is more than 1.2-2 times under the same quality.

5. Use Less, perform better, and be more economical with the same volume.

6. For the first time ozone elimination and efficient utilization of resources .

7. Composite multi-catalyst system, high ozone utilization rate, high mineralization rate .

8. The invention solves the problem of ozone secondary pollution caused by photolysis and plasma technology, improves the oxidation degree and purification efficiency, and upgrades the traditional technology.

- Product Details

- {{item.text}}

Quick Details

-

MF:

-

O3

-

EINECS No.:

-

0

-

Place of Origin:

-

SHAANXI

-

Brand Name:

-

AMBOHR

-

Model Number:

-

AOD-FW

-

Product name:

-

AOD-FW

-

Packing density:

-

1.6-8.0kg/m3(1.5-3.0mm)

-

Product packaging:

-

Barreled, 20kg/barrel

-

specific surface area:

-

≥500m2/g

-

efficiency:

-

≥80-95%

-

Recommend airspeed:

-

10000-50000h-1

-

Air Resistance:

-

≤800pa

Quick Details

-

CAS No.:

-

0

-

Purity:

-

≥90-99%

-

Other Names:

-

Supported manganese-based composite metal oxide

-

MF:

-

O3

-

EINECS No.:

-

0

-

Place of Origin:

-

SHAANXI

-

Brand Name:

-

AMBOHR

-

Model Number:

-

AOD-FW

-

Product name:

-

AOD-FW

-

Packing density:

-

1.6-8.0kg/m3(1.5-3.0mm)

-

Product packaging:

-

Barreled, 20kg/barrel

-

specific surface area:

-

≥500m2/g

-

efficiency:

-

≥80-95%

-

Recommend airspeed:

-

10000-50000h-1

-

Air Resistance:

-

≤800pa

Test Drive This Product

Still not sure? We offer free product samples for many of our products.

No strings attached. We believe in our products and we

think you will too, once you give them a try.

Get A

FREE

Sample >>>

Product Description

Product features

Details Images

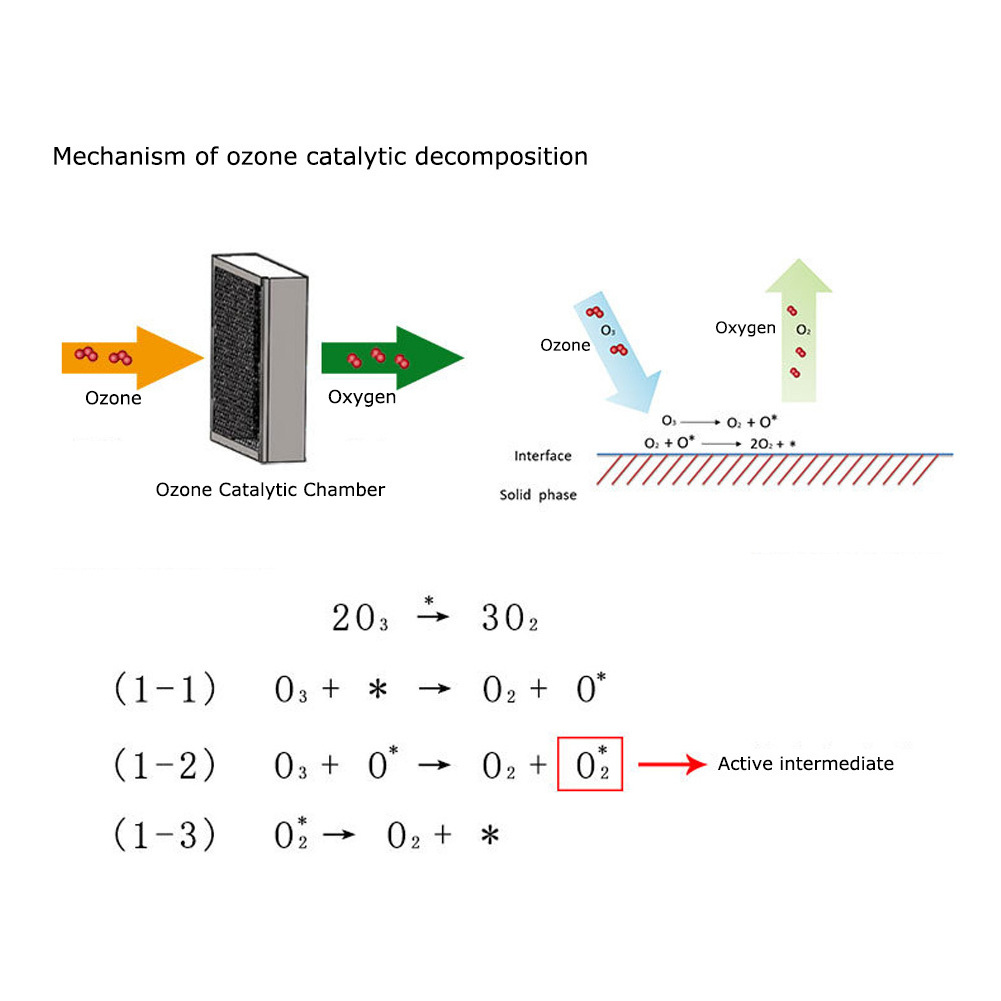

Product principle

Under the action of power system, ozone is decomposed into non-toxic oxygen after entering the nano-active sites on the inner and outer surfaces of ozone decomposed materials with high specific surface area at room temperature through ozone catalytic decomposition material bed or decomposition network, purification process zero energy consumption (excluding the power consumption of fans),zero chemicals. For example, in the condition of high humidity, it is generally recommended that the ozone gas be heated up to 50-100 °C after gas liquid separation unit, in order to restrain the accumulation of water on the catalyst and improve the stability of the catalyst.

Method of use

Ozone and exhaust gas into the catalyst surface at the same time, gas pipeline not short flow air leakage, all the gas through the catalytic network, the number of 2-4 layers.

Related Products

AOD Series product presentation notes

1.It can catalyze the decomposition of high concentration ozone into oxygen at room temperature/low

temperature. Proper heating is helpful to raise the rate of catalytic reaction. (40 ~ 90 °C) the effect is better. High

concentration and high humidity ozone tail gas needs gas-liquid separation device and preheating, low concentration of ozone at room temperature, without heating.

2.Mainly used for high concentration ozone pollution purification (O3≥500 ppm) , different from activated carbon supported catalyst, OC-KLM-01 ozone oxidation catalyst, is specifically used for the treatment of high concentration low flow ozone tail gas, it will not cause the decomposition process to produce a large amount of heat resulting in the combustion of the catalyst pulverization.

3.High activity, wide airspeed range.

4.the exhaust gas does not contain high concentrations of halogen-containing organic compounds, when high concentrations of ozone and halogen-containing organic compounds into the ozone catalyst, in the process of catalytic decomposition of ozone, some halogenated organic compounds will be catalytically oxidized to form a large number of intermediate products and acidic substances, which will accumulate on the catalyst for a long time and easily lead to the decline of catalyst activity.

5.the exhaust gas does not contain high concentrations of sulfur compounds (especially H2S, in the process of catalytic decomposition of ozone, a large number of intermediate products, especially sulfur solid, will accumulate on the catalyst for a long time, easy to cause the catalyst pore plugging failure.

6.The catalyst can be removed and placed in an oven at 100-150 °C if it is found that the activity of the catalyst decreases due to the accumulation of water over a long period of time after the catalyst has expired for a certain period of time (for example,about one year) , drying for several hours (if lack of conditions can be taken out in the strong sun exposure) , can be re-loaded into the purifier for use.

7.The deactivation of catalyst is reversible and irreversible, and the accumulation of water and other detachable substances is basically reversible, which can be regenerated by heating. The irreversible deactivation of the catalyst is due to the valence shift of the catalyst and the chemical bonding and reaction of other compounds with the active components of the catalyst.

temperature. Proper heating is helpful to raise the rate of catalytic reaction. (40 ~ 90 °C) the effect is better. High

concentration and high humidity ozone tail gas needs gas-liquid separation device and preheating, low concentration of ozone at room temperature, without heating.

2.Mainly used for high concentration ozone pollution purification (O3≥500 ppm) , different from activated carbon supported catalyst, OC-KLM-01 ozone oxidation catalyst, is specifically used for the treatment of high concentration low flow ozone tail gas, it will not cause the decomposition process to produce a large amount of heat resulting in the combustion of the catalyst pulverization.

3.High activity, wide airspeed range.

4.the exhaust gas does not contain high concentrations of halogen-containing organic compounds, when high concentrations of ozone and halogen-containing organic compounds into the ozone catalyst, in the process of catalytic decomposition of ozone, some halogenated organic compounds will be catalytically oxidized to form a large number of intermediate products and acidic substances, which will accumulate on the catalyst for a long time and easily lead to the decline of catalyst activity.

5.the exhaust gas does not contain high concentrations of sulfur compounds (especially H2S, in the process of catalytic decomposition of ozone, a large number of intermediate products, especially sulfur solid, will accumulate on the catalyst for a long time, easy to cause the catalyst pore plugging failure.

6.The catalyst can be removed and placed in an oven at 100-150 °C if it is found that the activity of the catalyst decreases due to the accumulation of water over a long period of time after the catalyst has expired for a certain period of time (for example,about one year) , drying for several hours (if lack of conditions can be taken out in the strong sun exposure) , can be re-loaded into the purifier for use.

7.The deactivation of catalyst is reversible and irreversible, and the accumulation of water and other detachable substances is basically reversible, which can be regenerated by heating. The irreversible deactivation of the catalyst is due to the valence shift of the catalyst and the chemical bonding and reaction of other compounds with the active components of the catalyst.

Advisory guidelines

Before consulting dosage, please provide the following specific parameters:

Composition

: Main components of exhaust gas

Concentration : Concentration of waste gas to be treated

Air volume : Fan air volume

Temperature : Gas temperature

Humidity : Gas humidity

Concentration : Concentration of waste gas to be treated

Air volume : Fan air volume

Temperature : Gas temperature

Humidity : Gas humidity

Product Application

Use scenario

1. Industrial VOCs, Odors, Lampblack and other pollutants purification process of ozone by-products of equipment and engineering; UV photolysis, plasma, high-voltage static electricity, ozone generator and other equipment

2. Plastic recycling, spraying, printing, electronic manufacturing, paint and other industries waste gas purification and garbage in the loading station and other odorous places

3. The efficient elimination and utilization of ozone in many fields such as the place where the VOCs Waste Gas with low concentration is produced

4. The ozonation catalyst is designed and developed for the purification of high concentration ozone pollution (especially O3≥500 ppm) , and is also safe and effective for the purification of low concentration ozone (O3 < 500 ppm) , fast catalytic decomposition of ozone to non-toxic oxygen.

5. ozone generator generated residual ozone (high, medium and low concentrations of 4 ozone) in all occasions

2. Plastic recycling, spraying, printing, electronic manufacturing, paint and other industries waste gas purification and garbage in the loading station and other odorous places

3. The efficient elimination and utilization of ozone in many fields such as the place where the VOCs Waste Gas with low concentration is produced

4. The ozonation catalyst is designed and developed for the purification of high concentration ozone pollution (especially O3≥500 ppm) , and is also safe and effective for the purification of low concentration ozone (O3 < 500 ppm) , fast catalytic decomposition of ozone to non-toxic oxygen.

5. ozone generator generated residual ozone (high, medium and low concentrations of 4 ozone) in all occasions

6. Treatment of ozone tail gas from L Ozonation of wastewater

7. high efficient elimination and utilization of ozone in many fields, such as sterilization and disinfection of medical instruments, ozone pollution purification after odor elimination in public places

7. high efficient elimination and utilization of ozone in many fields, such as sterilization and disinfection of medical instruments, ozone pollution purification after odor elimination in public places

Product Catalog

Our Advantages

A

fter Sales Services

•

One year warranty and lifetime maintenance.

M

ultilingual Staff

•

We support Global partners with our experienced and qualified, multilingual staff.

B

ear Responsibility

•

100% accountability / 0 excuses.

O

nline 24*7

•

Online 24*7 service to solve your problems

H

igh Quality

•

Our products have passed SAA, UL, CE, RoHS and other certifications...

R

equests & Rest

•

You make requests, and we do the rest.

About Us

YOU MAKE REQUESTS, WE DO THE REST.

About Us

We support a network of national and global partners with our experience and our qualified, multilingual staff. Partnership and

long-term cooperation are very important to us..

We are very attentive to the needs of our customers and can thus constantly expand our product range. Customer service and a

growing product range with an attractive price / performance ratio can be offered.

Let us know, we look forward to working with you.

Q1: What's your warranty ?

A1: The warranty is 1 year. We deliver new and faultless products. Also, we are responsible to repair and replace the defective ones in the warranty period, meanwhile we provide life-long free technical support and maintenance.

Q2: How to proceed an order?

A2: 1. let us know your requirements or application.

2. We quote according to your requirements or our suggestions.

3. You confirm the samples and place deposit for formal order.

4. We arrange the production.

Q3: What's the standard of package?

A3: Inner box and out carton are made as per international standard. We also can make special design according to your needs.

And if necessary, goods will be packed by pallet to avoid any damage.

Q4: Could you do OEM/ODM?

A4: Sure,OEM/ODM is acceptable, and please supply with the brand letter of Authorization.

Q5: What is the payment terms?

A5: T/T, Western Union and L/C is acceptable. Moreover, you can place order on Alibaba though Trade Assurance.

Q6: What' your advantages?

A6: 1. We can provide the most comprehensive products.

2. We have the professional engineer team which can provide free consultation and design services. The customize will be according

to your drawings or samples.

3. Your inquire will be replied within 6 hours any time.

4. Our Freight forwarders are faster, safer, and more convenient, and we can make sure the delivery on time.

Sales Promotion

Hot Searches