4.

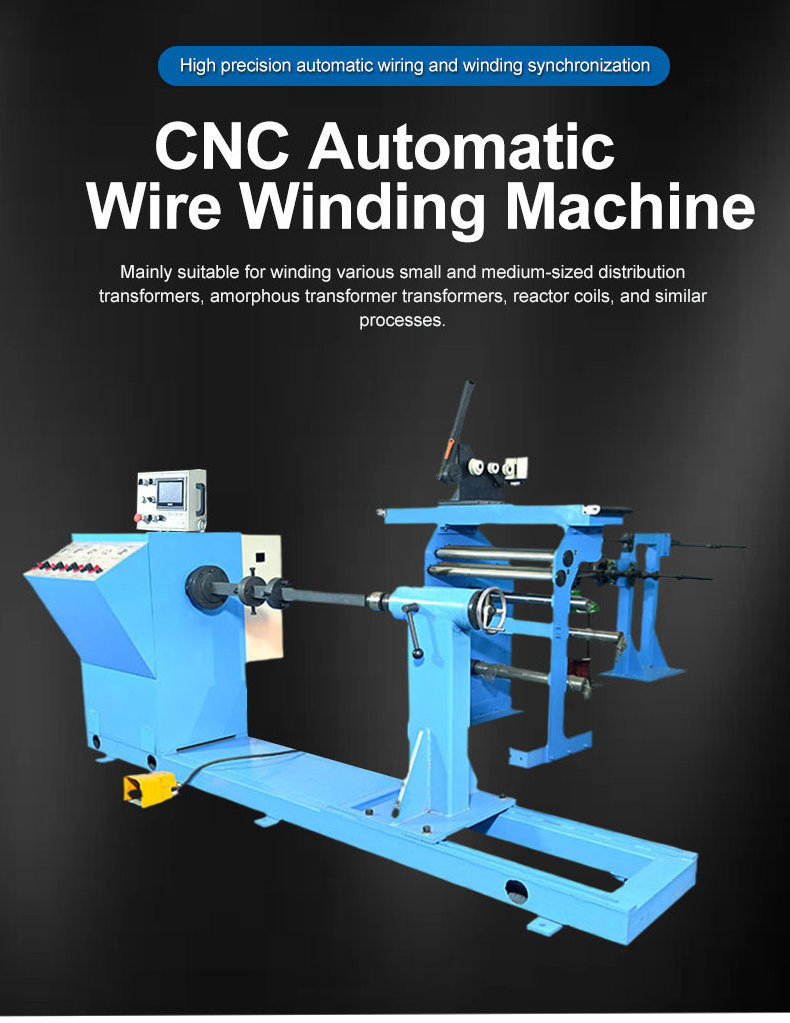

Before winding, different wire gauges can be used

Before winding, the automatic wire spacing can be conveniently set according to different wire specifications. During the winding process, possible errors can be adjusted through wire diameter compensation and manual adjustment to ensure the tightness of the coil.

5.

Desktop control box

The desktop control box is located on the upper part of the winding main chassis, which is convenient to use, simple, and has a clear interface

The desktop control box is located on the upper part of the winding main chassis, which is convenient to use, simple, and has a clear interface