- Product Details

- {{item.text}}

Quick Details

-

Jaw stroke of pneumatic chuck:

-

3.7 mm of pneumatic chuck

-

Max. static clamping force of chuck:

-

2856 kgf of pneumatic chuck

-

Max. static holding of chuck:

-

1836 kgf of pneumatic chuck

-

Permission pressure of pneumatic chuck:

-

0.4-0.8 Mpa of pneumatic chuck

-

Limit speed of pneumatic chuck:

-

4000 r/min of pneumatic chucks

-

Clamping range of pneumatic chuck:

-

10-140 of pneumatic chucks

-

Holding range of pneumatic chuck:

-

25-140 of pneumatic chuck

-

Net weight of pneumatic chuck:

-

12 kg of pneumatic chuck

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Name of lathe chuck:

-

Automatic metal lathe machine 4 jaw chuck

-

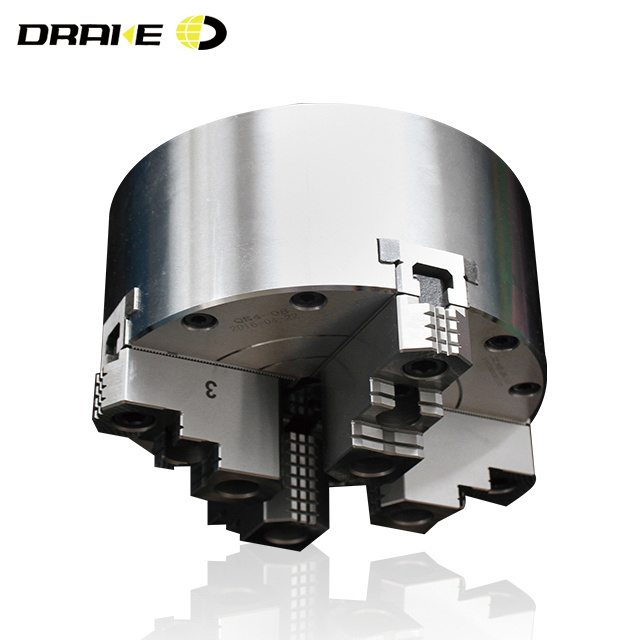

Structure of Chuck:

-

Built-in Cylinder of pneumatic chuck

-

Jaw stroke of pneumatic chuck:

-

3.7 mm of pneumatic chuck

-

Max. static clamping force of chuck:

-

2856 kgf of pneumatic chuck

-

Max. static holding of chuck:

-

1836 kgf of pneumatic chuck

-

Permission pressure of pneumatic chuck:

-

0.4-0.8 Mpa of pneumatic chuck

-

Limit speed of pneumatic chuck:

-

4000 r/min of pneumatic chucks

-

Clamping range of pneumatic chuck:

-

10-140 of pneumatic chucks

-

Holding range of pneumatic chuck:

-

25-140 of pneumatic chuck

-

Net weight of pneumatic chuck:

-

12 kg of pneumatic chuck

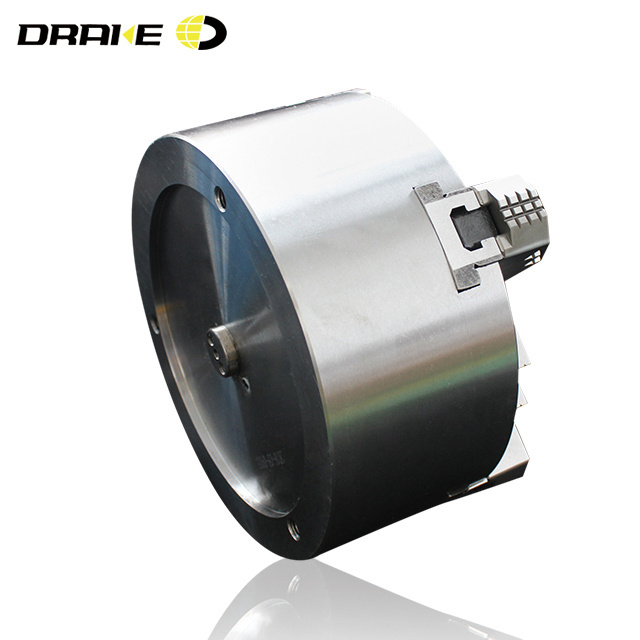

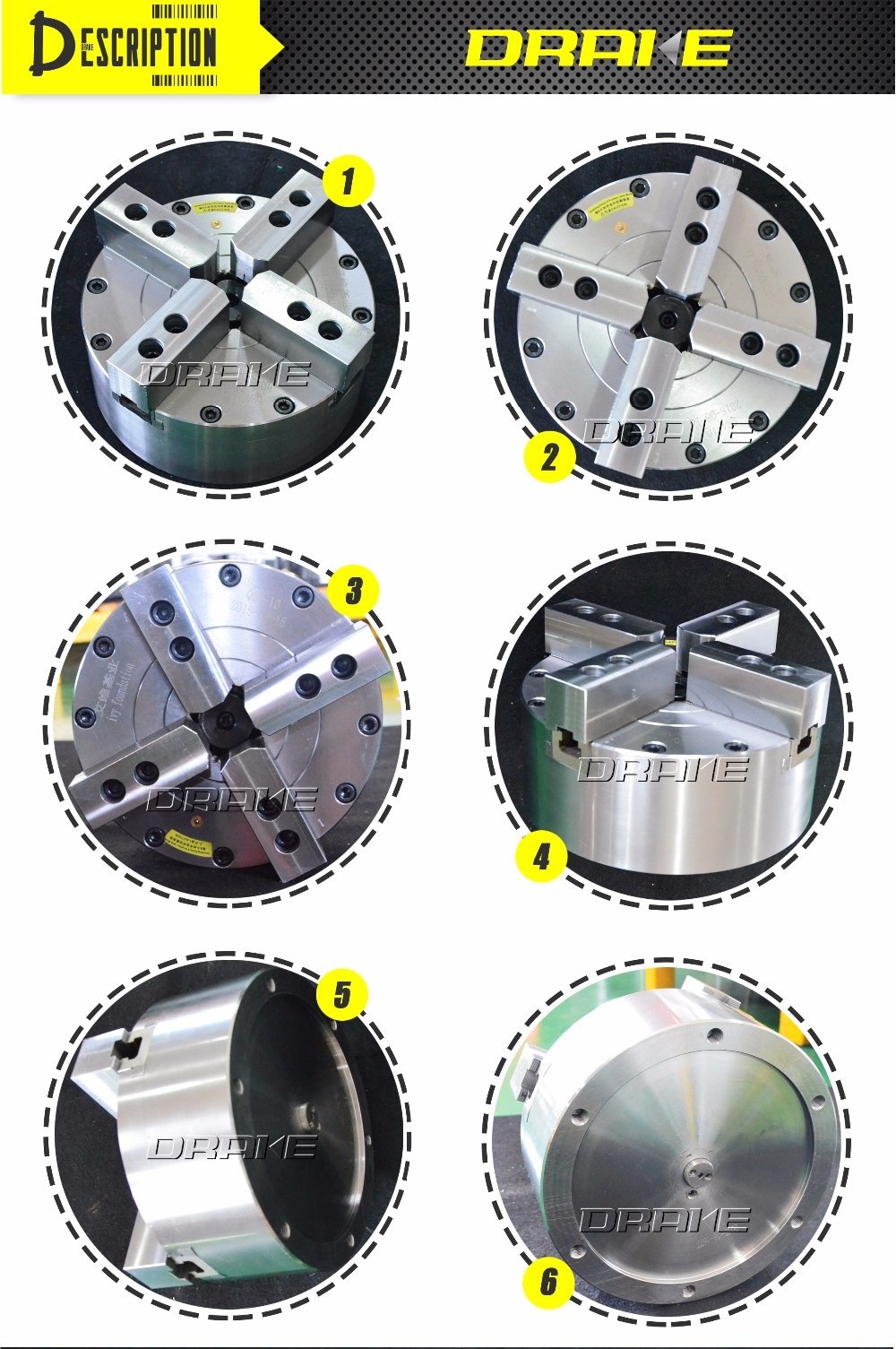

Automatic metal lathe machine 4 jaw chuck

Technical features:

1. The chuck is a built-in cylinder with large clamping force, good sealing, high

precision, safety and reliability, nice economical and pracitical applicability

and long serve life.

2. The chuck can be used for precessing square parts and other special-shaped parts.

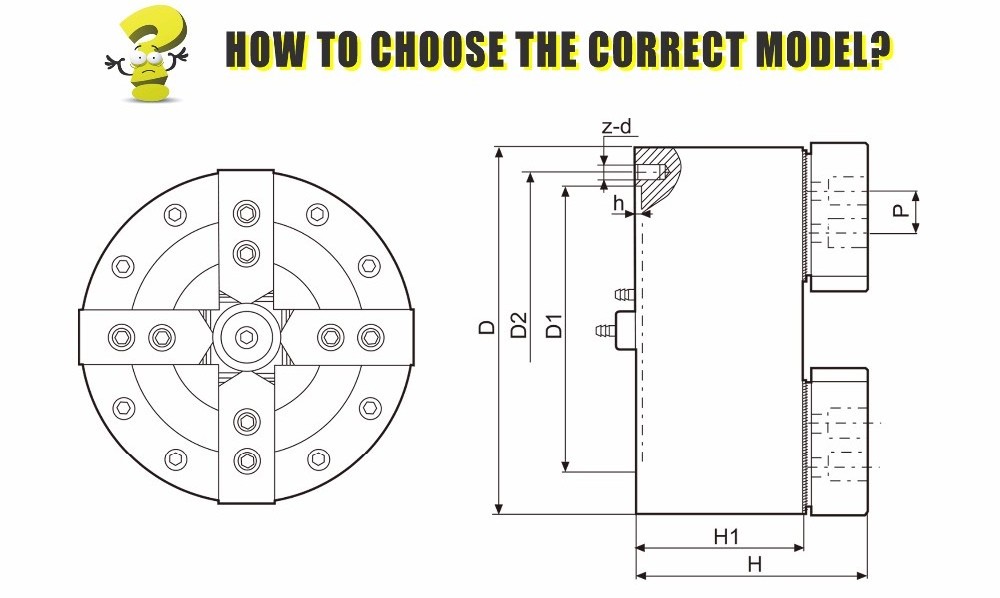

There are three questions to answer to aid the correct choice of power chuck:

1. Type and model of CNC lathe.

2. Length of workpiece?

3. Outer diameter of workpiece?

4. Processing requirement?

Size Parameters

| Model/Spec. | D | D1 | D2 | H | H1 | h | P | z-d |

| QS4-05" | 135 | 95 | 108 | 118 | 85 | 4 | 18 | 3-M8 |

| QS4-06" | 180 | 130 | 142 | 130 | 93 | 4 | 20 | 3-M8 |

| QS4-08" | 208 | 165 | 180 | 136 | 100 | 5 | 25 | 3-M10 |

| QS4-10" | 252 | 206 | 226 | 143 | 102 | 5 | 30 | 3-M10 |

| QS4-12" | 322 | 270 | 290 | 160 | 115 | 6 | 30 | 6-M12 |

| QS4-15" | 400 | 340 | 368 | 168 | 118 | 6 | 43 |

6-M16 |

It is recommended to grease chucks at least twice a day in order to maximize longevity

Performance Parameters

|

Model/Spec. |

Jaw Stroke (Diameter) (mm) |

Maximum static clamping force(kgf) |

Maximum static holding force(kgf) |

Permissible pressure(mm) |

Limit speed (r/min) |

Clamping range |

Holding range |

Net weight (Kg) |

| QS4-05" | 3.7 | 2856 | 1836 | 0.4-0.8 | 4000 | 10-140 | 25-140 | 12 |

| QS4-06" | 4.2 | 4896 | 2652 | 0.4-0.8 | 3600 | 15-180 | 30-180 | 14 |

| QS4-08" | 5 | 7140 | 4284 | 0.4-0.8 | 3300 | 20-220 | 40-240 | 24 |

| QS4-10" | 6.5 | 9282 | 6120 | 0.4-0.8 | 3000 | 30-260 | 50-280 | 37 |

| QS4-12" | 8.5 | 14076 | 9486 | 0.4-0.8 | 2500 | 40-350 | 60-360 | 72 |

| QS4-15" | 12 | 19788 | 15096 | 0.4-0.8 | 2000 | 60-420 | 80-440 | 122 |

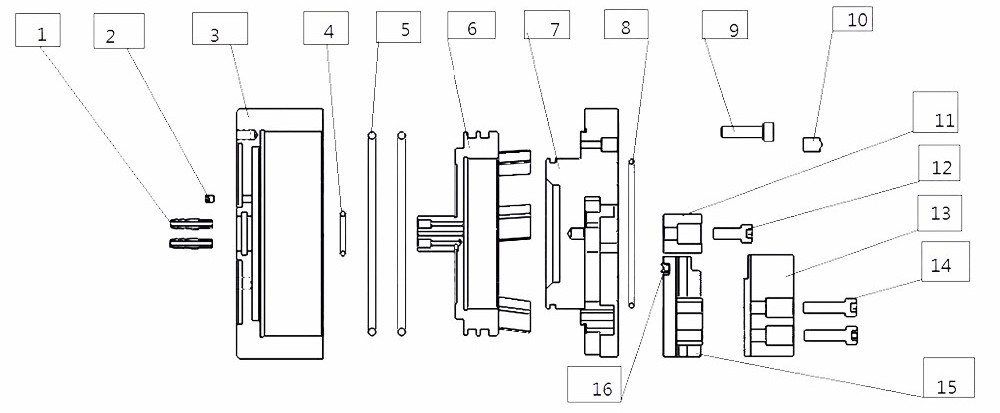

| No. | Name | No. | Name |

| 1 | Hose fitting M6 | 9 |

Hex.socket head bolt |

| 2 |

Hex.socket head bolt |

10 |

Grease nipple |

| 3 |

Body |

11 |

Center fixed cap |

| 4 |

O-type sealing ring |

12 |

Center fixed cap connection screw |

| 5 |

Cylinder O-type sealing ring |

13 |

Soft jaw |

| 6 |

Plunger |

14 |

Chuck jaw connection screw |

| 7 |

Cover plate |

15 |

Master jaw |

| 8 |

Cover plate O-type sealing ring |

16 |

Y-type sealing ring |

The matching products including:

1. soft jaws.

2. Oil-water separator, manual solenoid valve.

3. A ir hose, manual-switch, Hex. socket head bolt, axle sleeve.

4.

Pneumatic controller

Automatic metal lathe machine 4 jaw chuck Automatic metal lathe machine 4 jaw chuck Automatic metal lathe machine 4 jaw chuck Automatic metal lathe machine 4 jaw chuck