- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v-10kv

-

Power:

-

85000w

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

25000

-

Product name:

-

Sawdust dryer

-

Vaporization(t/h):

-

0.565-3.432

-

Early moisture(%):

-

35-50%

-

Final moisture(%):

-

12-15%(adjusting)

-

Temperature range(℃):

-

270±30℃

-

Application material:

-

Sawdust Biomass,wood chips

-

Feature:

-

Continuous Drying Machine

-

Color:

-

Customers Request

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support

Quick Details

-

Type:

-

Rotary Drying Equipment

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jiutian

-

Voltage:

-

220v-10kv

-

Power:

-

85000w

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

25000

-

Product name:

-

Sawdust dryer

-

Vaporization(t/h):

-

0.565-3.432

-

Early moisture(%):

-

35-50%

-

Final moisture(%):

-

12-15%(adjusting)

-

Temperature range(℃):

-

270±30℃

-

Application material:

-

Sawdust Biomass,wood chips

-

Feature:

-

Continuous Drying Machine

-

Color:

-

Customers Request

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support

Introduction

Wood chips dryer is special equipment designed and manufactured for the drying of wood chips, sawdust, wood flour, bamboo chips, and other materials. It has the characteristics of large drying output, significant energy-saving effect, and low maintenance.

Wood chips dryer is an important part of biomass fuel production equipment. By drying wood chips, they can be further pelletized to produce combustible biomass fuel. Sawdust dryer plays a vital role in the recycling of biomass fuel and is of great significance to promote economic development and environmental protection.

Our professional wood chips rotary dryer has played an important role in various drying industries, wood chips rotary dryer is used for drying materials with humidity or granularity in the industries of mineral dressing, building material, metallurgy, and chemical. wood chips rotary dryer can be used for drying many kinds of materials and with the convenient and reliable operation; therefore, it has been widely used.

Wood chips dryer is an important part of biomass fuel production equipment. By drying wood chips, they can be further pelletized to produce combustible biomass fuel. Sawdust dryer plays a vital role in the recycling of biomass fuel and is of great significance to promote economic development and environmental protection.

Our professional wood chips rotary dryer has played an important role in various drying industries, wood chips rotary dryer is used for drying materials with humidity or granularity in the industries of mineral dressing, building material, metallurgy, and chemical. wood chips rotary dryer can be used for drying many kinds of materials and with the convenient and reliable operation; therefore, it has been widely used.

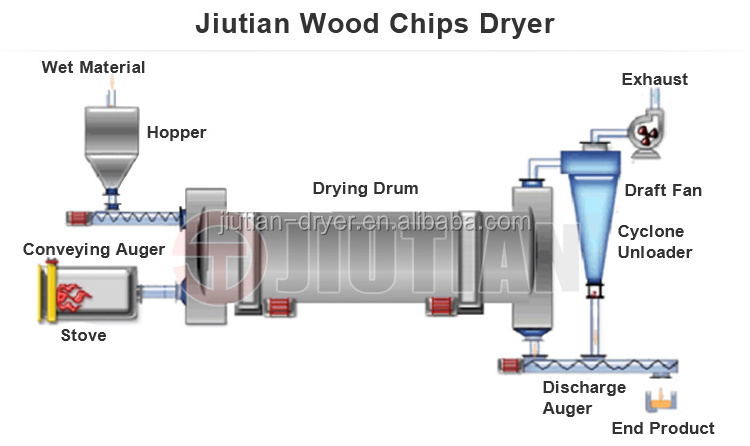

1. The material enters the inner layer of the rotary drum from the feeding device to achieve downstream drying. The material is continuously picked up and scattered under the inner layer of the copy plate to achieve heat exchange in a spiral manner. The material moves to the other end of the inner layer to enter In the middle layer, countercurrent drying is carried out. The material is continuously raised in the middle layer, showing a two-step forward and one-step travel mode. The material in the middle layer not only fully absorbs the heat emitted by the inner drum, but also absorbs the heat of the middle drum, and at the same time extends After the drying time, the material reaches the best dry state here.

2.The material travels to the other end of the middle layer and falls into the outer layer. The material travels in the outer drum in a rectangular multi-loop manner. The material that achieves the drying effect quickly travels out of the drum under the action of hot air, and the wet material that does not achieve the drying effect is caused by its own weight. Can not move fast, the material is fully dried in this rectangular copy board, thus achieving the purpose of drying.

2.The material travels to the other end of the middle layer and falls into the outer layer. The material travels in the outer drum in a rectangular multi-loop manner. The material that achieves the drying effect quickly travels out of the drum under the action of hot air, and the wet material that does not achieve the drying effect is caused by its own weight. Can not move fast, the material is fully dried in this rectangular copy board, thus achieving the purpose of drying.

1. PLC smart control & high automaticity. The performance of the rotary dryer and moisture content of dry materials is

automatically controlled in stable states.

2. High heat efficiency. The design of multiple circumferential flight combinations and flow rate adjustment devices ensures the control of the drying period and temperature distribution. The effect of insulation is as high as 70% and raises heat efficiency by 20%.

3. Four-wheel drive, more steady and stable.

4. Save 50% space compared with traditional dryers and reduce 50% civil investment.

5. Convenient variable frequency control systems. The customer could change the material flow rate and product moisture based on their needs.

6. Environmental and safe. Modular configuration of dust collection and purification systems

7. More choice for novel air furnaces with high efficiency, convenient manipulation, and energy control, which could reduce 30% energy cost and 20% electric cost.

automatically controlled in stable states.

2. High heat efficiency. The design of multiple circumferential flight combinations and flow rate adjustment devices ensures the control of the drying period and temperature distribution. The effect of insulation is as high as 70% and raises heat efficiency by 20%.

3. Four-wheel drive, more steady and stable.

4. Save 50% space compared with traditional dryers and reduce 50% civil investment.

5. Convenient variable frequency control systems. The customer could change the material flow rate and product moisture based on their needs.

6. Environmental and safe. Modular configuration of dust collection and purification systems

7. More choice for novel air furnaces with high efficiency, convenient manipulation, and energy control, which could reduce 30% energy cost and 20% electric cost.

|

Model

|

Input

(t/h)

|

Initial Moisture

(%)

|

Final Moisture

(%)

|

Drying Temperature

(℃)

|

Power

(kw)

|

Area

(m²)

|

||||||

|

JTSG

1409

|

1.53

|

40±5

|

15% (Adjustable)

|

280±30℃

|

34

|

5m×15m

|

||||||

|

JTSG

1615

|

2.89

|

|

|

|

45

|

6m×22m

|

||||||

|

JTSG

2008/3

|

5.2

|

|

|

|

78

|

8m×16m

|

||||||

|

JTSG

2010/3

|

6.63

|

|

|

|

90

|

8m×18m

|

||||||

|

JTSG

2210/3

|

7.24

|

|

|

|

105

|

8m×20m

|

||||||

|

JTSG

2510/3

|

8.91

|

|

|

|

125

|

10m×20m

|

||||||

|

JTSG

2512/3

|

10.5

|

|

|

|

140

|

10m*24m

|

||||||

|

JTSG

2912/3

|

12.14

|

|

|

|

155

|

10m*24m

|

||||||

|

Note: The price above is just for reference, please feel free to contact us if you want to know more about different models or production lines. We can offer free customized proposals.

|

|

|

|

|

|

|

||||||

Hot Searches