- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

610

-

Dimension(L*W*H):

-

4200x2480x2950mm

-

Weight (T):

-

6.1 T

-

Positioning Accuracy (mm):

-

0.010

-

Repeatability (X/Y/Z) (mm):

-

0.008

-

Range of Spindle Speed(r.p.m):

-

0 - 10000 r.p.m

-

Spindle Motor Power(kW):

-

11/15

-

Max. Table Load(kg):

-

1000 kg

-

Feed Speed(mm/min):

-

1 - 20000 mm/min

-

Rapid Feed Speed(m/min):

-

200

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

SMTCL

-

Voltage:

-

220V/380V/customized

-

Brand:

-

SMTCL

-

Product name:

-

VMC 1100B

-

CNC or Not:

-

CNC

-

Table size:

-

1300x610mm

-

X /Y/Z Axis travel:

-

1100mm/610mm/650mm

-

X/Y/Z axis rapid speed:

-

45/45/30 m/min

-

Spindle speed:

-

20000 r/min

-

Control system:

-

GSK SIEMENS FANUC

-

Main motor power:

-

11/15KW

-

After-sales Service Provided:

-

Video Technical Support

Quick Details

-

Table Size (mm):

-

1300x610

-

Number of Axes:

-

3, 4, 5

-

Table Travel (X) (mm):

-

1100

-

Table Travel (Y) (mm):

-

610

-

Dimension(L*W*H):

-

4200x2480x2950mm

-

Weight (T):

-

6.1 T

-

Positioning Accuracy (mm):

-

0.010

-

Repeatability (X/Y/Z) (mm):

-

0.008

-

Range of Spindle Speed(r.p.m):

-

0 - 10000 r.p.m

-

Spindle Motor Power(kW):

-

11/15

-

Max. Table Load(kg):

-

1000 kg

-

Feed Speed(mm/min):

-

1 - 20000 mm/min

-

Rapid Feed Speed(m/min):

-

200

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

SMTCL

-

Voltage:

-

220V/380V/customized

-

Brand:

-

SMTCL

-

Product name:

-

VMC 1100B

-

CNC or Not:

-

CNC

-

Table size:

-

1300x610mm

-

X /Y/Z Axis travel:

-

1100mm/610mm/650mm

-

X/Y/Z axis rapid speed:

-

45/45/30 m/min

-

Spindle speed:

-

20000 r/min

-

Control system:

-

GSK SIEMENS FANUC

-

Main motor power:

-

11/15KW

-

After-sales Service Provided:

-

Video Technical Support

Product Description

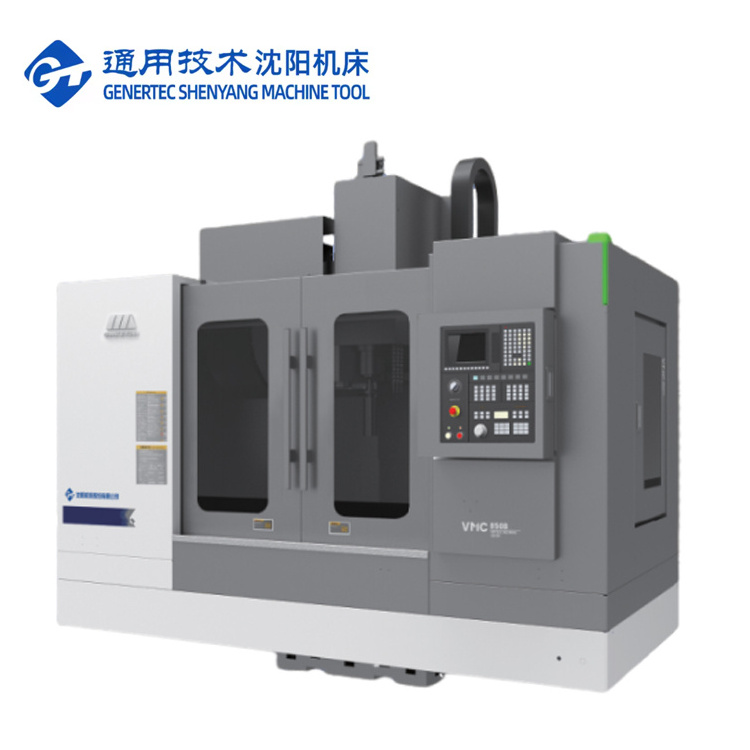

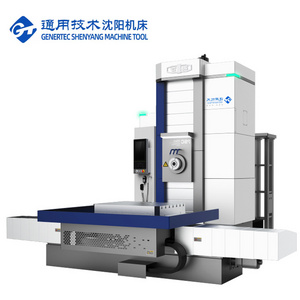

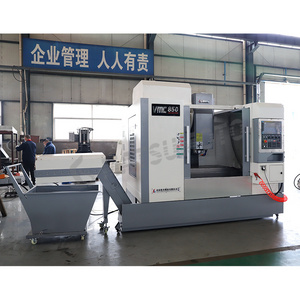

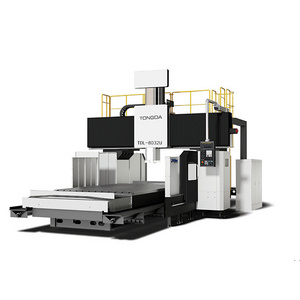

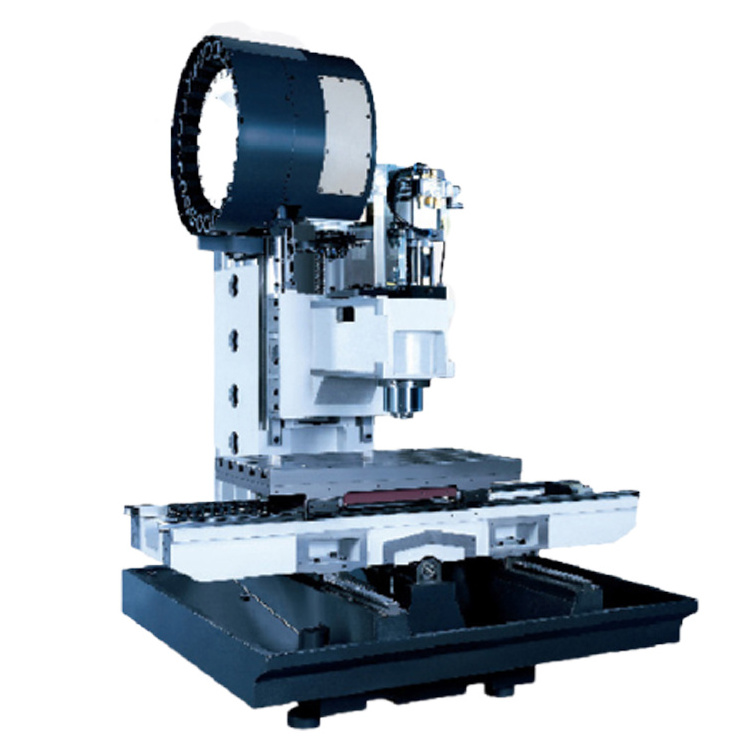

VMC 1100B

Typical Series

Vertical Machining Center

VMC-B

through the typical series product description is a combination of market demand and development of a product, it is not only complete specifications, from the table 800×420mm to 2200×800mm, X-axis travel from 700mm to 2100mm; From the spindle configuration, we also achieve a variety, from the standard belt connection, direct connection 8000 to the output of 380Nm large torque.

VMC-B

is a very cost-effective typical machine tool, ultra wide bed design to ensure the machine has the best support capacity and stability, and the bed adopts a large bevel structure, Y axis adopts split protection, making chip removal convenient and fast.

Product Features

1、Classical Structure Design

◆ Super wide beveled bed

◆ Split cover of Y-axis

◆ Multistage filtered chain plate chip conveyo

2、New Update and Improvemer

◆ Improved the thermal stability of lead screw

◆ Improved the seal class of cover

◆ Reduced the thermal deformation of headstock

3、High Configuration, Wide Applicability

◆ Large machining range

◆ Standard chain plate chip conveyor

◆ 11/15 kw main motor

Product Details

Motor:

Three-axis servo motor, which has smooth rotation characteristics, with the built-in encoder for high-speed and high-precision positioning control. Z-axis adopts no counterweight structure, which further improves the positioning accuracy and dynamic characteristics of the machine tool.

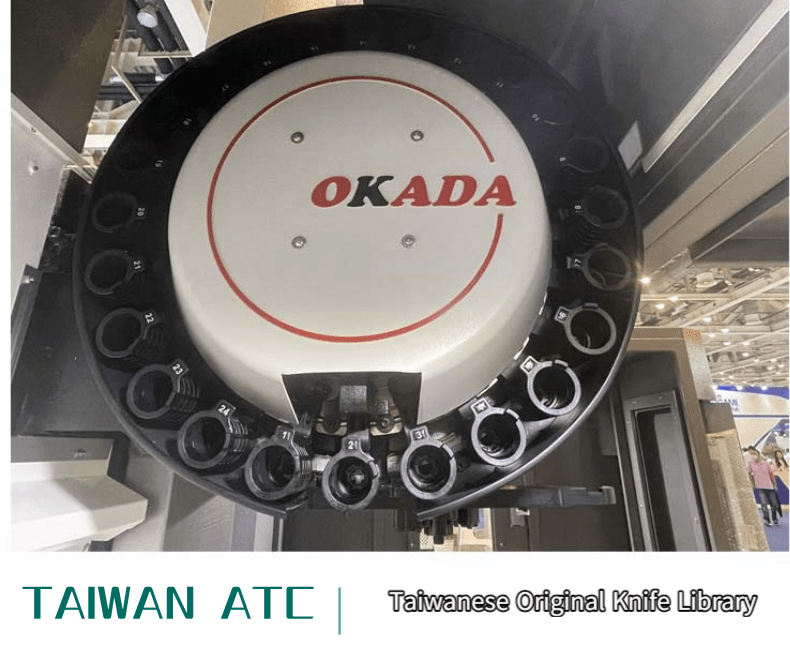

Tool Magazine:

Using a disc tool store, installed on the side of the column, to achieve high-speed noiseless operation, so that the tool change process is fast and accurate

Lead screw:

The three-axis servo motor is directly connected with the high-precision ball screw through the elastic coupling, reducing the intermediate link, realizing the gashless transmission, flexible feed, accurate positioning, and high transmission precision

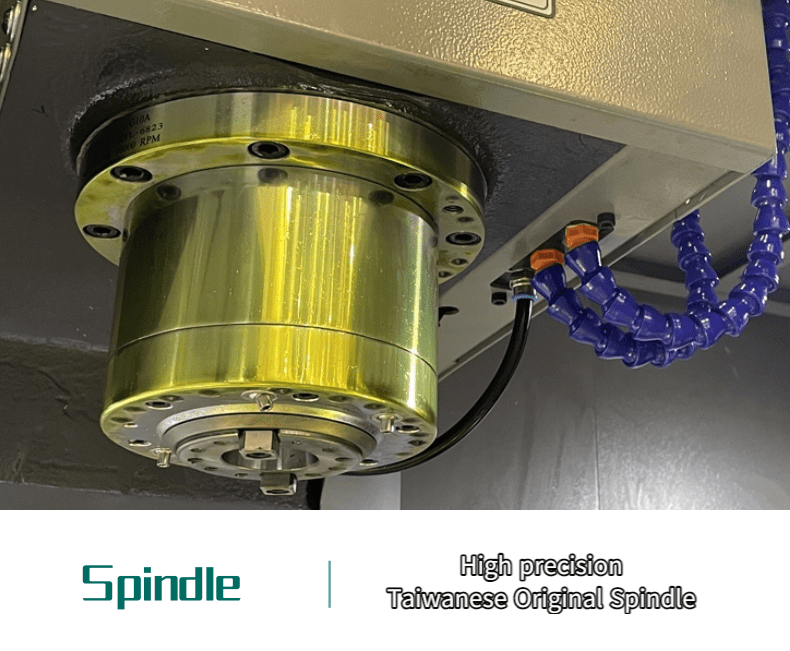

Main Axis:

Produced by professional manufacturers in Taiwan, P4 spindle special bearings are used, and the main transmission system is driven by synchronous belt to ensure the spindle rotation accuracy

Rail:

The three-axis guide pair adopts imported rolling linear guide, which has low static and static friction, high sensitivity, high positioning accuracy and good servo drive performance

Product Paramenters

|

Item

|

|

Unit

|

VMC 1100B

|

|

|

Capacity

|

X axis travel

|

mm

|

1100

|

|

|

|

Y axis travel

|

mm

|

610

|

|

|

|

Z axis travel

|

mm

|

650

|

|

|

|

Spindle nose to table surface

|

mm

|

150-800

|

|

|

Worktable

|

Table size (L×W)

|

mm

|

1300×610

|

|

|

|

Max load on the table

|

kg

|

1000

|

|

|

|

T-slot size

|

mm

|

18×5

|

|

|

Spindle

|

Spindle speed

|

r/min

|

10000

|

|

|

|

spindle shank 7:24

|

|

BT40

|

|

|

|

Spindle motor

|

kw

|

11/15

|

|

|

|

Maximum output torque

|

N.m

|

52.5

|

|

|

Feed rate

|

X/Y/Z rapid traverse

|

M/min

|

45/45/30

|

|

|

|

Feed rate

|

MM/min

|

1-20000

|

|

|

A.T.C

|

Tool storage capacity

|

pc

|

24

|

|

|

|

Maximum tool length

|

mm

|

300

|

|

|

|

Tool change time

|

sec

|

2.5

|

|

|

Accuracy

|

Positioning accuracy X/Y/Z

|

mm

|

0.010/0.008/0.010

|

|

|

|

Repeatability positioning X/Y/Z

|

mm

|

0.008/0.006/0.008

|

|

|

Others

|

Overall dimensions(L×WxH)

|

mm

|

4200×2480×2950

|

|

|

|

Net machine weight

|

kg

|

6100

|

|

|

|

Total power requirment

|

KVA

|

25

|

|

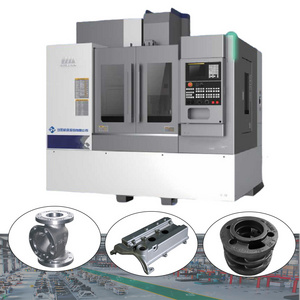

Industry application

Recommend Products

OUR Service

1. Assemble and debug before delivery

2. Respond within 24 hours and proceed to deal with the problem.

3. 1 year free repair service (no-human damage only).

4. Overall solution provided

2. Respond within 24 hours and proceed to deal with the problem.

3. 1 year free repair service (no-human damage only).

4. Overall solution provided

Why Choose Us

◆ Top quality sense, customers' requests come first

◆ High-tech manufacturer with research anddesign capacity

◆ Stable and mature supplying system

◆ Young active sales and engineers for instant services(24 hours online)

◆ Upgrading on mechanism according to ergonomics and easy maintenance

◆ Our structure design principle: easy maintenance & installation, low cost maintenance, not affect production

◆ 30 years + R & D history, the company was founded in 1993

◆ High-tech manufacturer with research anddesign capacity

◆ Stable and mature supplying system

◆ Young active sales and engineers for instant services(24 hours online)

◆ Upgrading on mechanism according to ergonomics and easy maintenance

◆ Our structure design principle: easy maintenance & installation, low cost maintenance, not affect production

About Us

Welcome to visit us!

Shanghai HD M&E Tech Co., Ltd is located in Shanghai, China. We specialize in CNC lathe, vertical machining center, horizontal machining center, gantry machining center, five-axis machining center, turn-milling center and various other CNC equipment. We have more than 200 kinds of machine tools. The quality and technology of products have reached the international advanced level.

SMTCL and SYMG

group

is our cooperating factory. It has over 80 years’ history of manufacturing machine tools. The first lathe, drilling machine and boring machine were all born here. They have been one of the leader of China's Machine Tool industry and the largest machine tool manufacture in China.

Machine tool products cover automobiles, aviation, new energy, construction machinery, ships, pump valves, bearings, 3C electronics, molds and other industries.

We take the mission of providing the machine tools with leading technology, high quality and good service to our customers all over the world!

Our Factory

Partners

Exhibition

Our Certifications

International Market

Packaging & Delivery

FAQ

Q1. Are you a trade company or manufacturing company?

We are a manufacturing company.

Q2. What's your main products of your company?

We specialized in all kinds of machines, such as CNC Lathe, CNC Milling Machine, Vertical Machining Center,Conventional Lathe, Drilling Machine, Radial Drilling Machine, and so on.

Q3. Can you provide customized machine or SPM (Special purpose machine)?

Yes, we provide Smart CNC solutions for our customer in order to increase efficiency.

Q4: What's your warranty terms?

We will supply a replacement for parts that prove to be defective for a period of 12 months,

starting on the machine's bill of lading date.

starting on the machine's bill of lading date.

Q5. What is the services?

Pr-sales: Customized solutions, planning and design;One-to-one service

After sales: 7 days 24 hours on line service, Remote guidance of installation, docking with customer software system

Pr-sales: Customized solutions, planning and design;One-to-one service

After sales: 7 days 24 hours on line service, Remote guidance of installation, docking with customer software system

Q6: Why choose your company?

Products from the development, design, manufacture, assembly of the entire production process are

carried out between plants with a complete production chain which is your most reliable guarantee.

carried out between plants with a complete production chain which is your most reliable guarantee.

Q7: Can your company send the technical personnel to our company and direct our workers overseas?

We can supply this kind of service. When the machines arrive the buyer's installation site, we can timely send mechanical and electrical engineers to install according to the buyer's schedule. All these can be quoted and list in the contract. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.

Q8: What's the Payment Terms?

T/T 30% initial payment when order, 70% balance payment before shipment. irrevocable letter ofcredit at sight

Hot Searches