- Product Details

- {{item.text}}

Quick Details

-

keyword:

-

oil centrifuge

-

name:

-

waste oil purification centrifuge separator

-

Capacity:

-

1500(water flow)

-

Drum diameter:

-

270mm

-

Pump pressure:

-

≥0.2MPa

-

Vibration speed:

-

≤4.5 mm/s

-

Moisture in the material:

-

less than 1%-2%

-

Separation temperature:

-

95~98°C(waste oil water separation)

-

materials:

-

304/ 316L stainless steel

-

discharge way:

-

manual discharging for oil water separator

Quick Details

-

Brand Name:

-

FIVEMEN

-

Model Number:

-

KYDR203CD-23

-

Place of Origin:

-

Jiangsu, China

-

keyword:

-

oil centrifuge

-

name:

-

waste oil purification centrifuge separator

-

Capacity:

-

1500(water flow)

-

Drum diameter:

-

270mm

-

Pump pressure:

-

≥0.2MPa

-

Vibration speed:

-

≤4.5 mm/s

-

Moisture in the material:

-

less than 1%-2%

-

Separation temperature:

-

95~98°C(waste oil water separation)

-

materials:

-

304/ 316L stainless steel

-

discharge way:

-

manual discharging for oil water separator

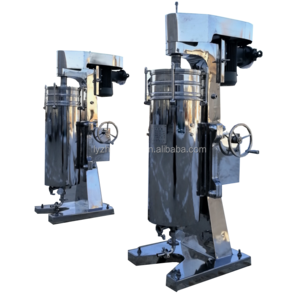

Lab centrifuge separator small oil centrifuge for fuel water separator

More than twenty years of successful industry experience

The best materials and strict control system

Equipment quality gaurantee

original design for customized service

| Product Description |

Introduction:

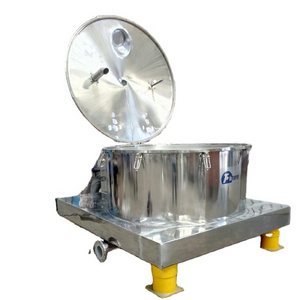

SYDR 302 is mainly used for the separating test of incompatible liquid-solid or liquid –liquid –solid materials, featuring compact size, It is ideal for use in universities and scientific research institutes.

This model is manual slag discharge separator with high separation efficiency and less material loss. It also has the

advantages of convenient installation and simple operation. It is the first choice for materials with less mechanical impurities.

This machine has undergone accurate dynamic balance verification, with minimal vibration, can run for a long time, and is safe and reliable to use. The interface is simple, saving a certain amount of space for users.

Main Feature:

1.This model is smallest oil water separator, which is manual slagging type,

high separation efficiency,

2.Can be automatic controlled according to requirements which greatly reduce the lab orintensity

of the operating.

3.This machine by the accurate calibration balancing,little vibration,can be long running and operated safety and reliable.

4, Application for lab and trial production

Application:

solid liquid separation---bacteria, juice, Chemical or pharmaceutical products ect

Liquid liquid solid separation---- olive oil, avocado oil, other vegatble oil, animal oil , waste oil ect

Moled and Parameters:

|

Capacity |

L/h |

10-100L/H |

|

Separation factor |

|

8500 |

|

Drum speed |

r/min |

9500 |

|

Slag discharge way |

|

Manual way |

|

Drum slag cavity volume |

L |

0.6 |

|

start method |

|

Friction to start |

|

Each discharge quantity |

L |

0.6 |

|

Liquid output pressure |

MPa |

≥0.05 |

|

Liquid intput pressure |

MPa |

0-0.2 |

|

Power |

kW |

1.1 |

|

Net Weight |

kg |

95 |

|

Specification |

L×W×H(mm×mm×mm) |

500×330×610 |

|

Packing size |

L×W×H(mm×mm×mm) |

800×500×700 |

|

Gross Weight |

kg |

115 |

|

No. |

Model |

Capacity (l/h) |

Drum diameter (mm) |

Drum speed |

Motor Power (KW) |

Discharge way |

Separator factor |

Weight(kg) |

Size(mm*mm*mm) |

|

1 |

KYDR203CD-23 |

1500 |

230 |

6930 |

2.2 |

Manual |

6170 |

245 |

850*625*985 |

|

2 |

KYDH204SD-23 |

2000 |

270 |

7200 |

4 |

Automatic |

6950 |

550 |

865*645*1100 |

|

3 |

KYDH206SD-23 |

3000 |

315 |

6500 |

5.5 |

Automatic |

7000 |

650 |

900*600*1150 |

|

4 |

KYDH207SD-23 |

4000 |

385 |

6500 |

7.5 |

Automatic |

7500 |

750 |

1100*1050*1250 |

|

5 |

KYDH209SD-23 |

5000 |

430 |

6000 |

11 |

Automatic |

8050 |

900 |

1200*950*1400 |

|

6 |

KYDH211SD-23 |

10000 |

500 |

5500 |

18.5 |

automatic |

8000 |

1200 |

1250*1000*1550 |

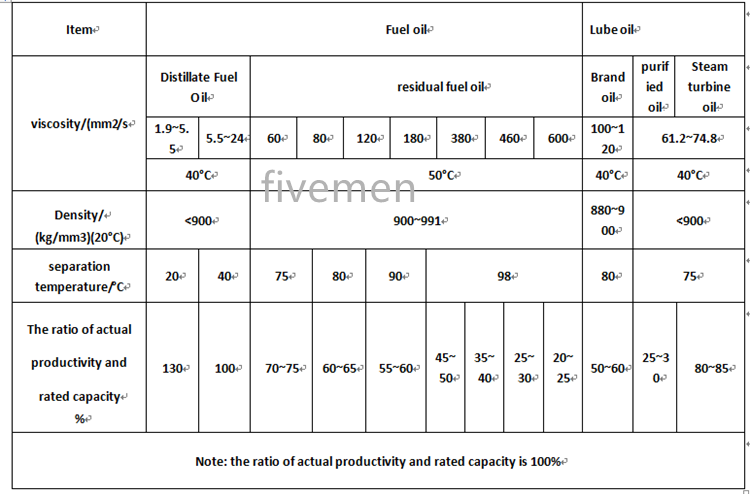

Speration conditions and actual productioivity of mineral oil:

STRUCTURE

Main parts 1. Access device 2.drum 3.paring disc device 4.drive system 5.stainless steel cover 6.engine base 7.Motor

(1).Machine starts the friction to start off, about six to ten minutes. The machine runs smoothly, low noise and vibration, the installation path is very easy to operate.

(2)The main strengthen parts of Roller body and Roller cover use 2Cr13, and the other parts of contacted materials such as Disc all use 316L

(3)The Stainless steel cover use SUS304

(4)The base use casting steel, coating does the same way as ship bottom.

|

Packing & Shipping |

The parts are bolted to the wooden cases. with layers of plastic and standard wooden cases

for packaging, it provide safe and convenient shippings.