- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

220V/ 380V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OEM

-

Dimension(L*W*H):

-

3000*710*1700mm

-

Weight:

-

500 KG

-

Packing speed:

-

5000-15000bags/hr

-

Filling range:

-

10-300ml(customized)

-

Size:

-

3000*710*1700mm

-

Power:

-

5kw

-

Applicable bottle diameter:

-

Adjustable

-

Applicable bottle high:

-

Adjustable

-

Packaging:

-

Wooden case

-

Degree of automatic:

-

Automatic

Quick Details

-

Machinery Capacity:

-

8000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice, Other

-

Filling Accuracy:

-

99%

-

Voltage:

-

220V/ 380V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OEM

-

Dimension(L*W*H):

-

3000*710*1700mm

-

Weight:

-

500 KG

-

Packing speed:

-

5000-15000bags/hr

-

Filling range:

-

10-300ml(customized)

-

Size:

-

3000*710*1700mm

-

Power:

-

5kw

-

Applicable bottle diameter:

-

Adjustable

-

Applicable bottle high:

-

Adjustable

-

Packaging:

-

Wooden case

-

Degree of automatic:

-

Automatic

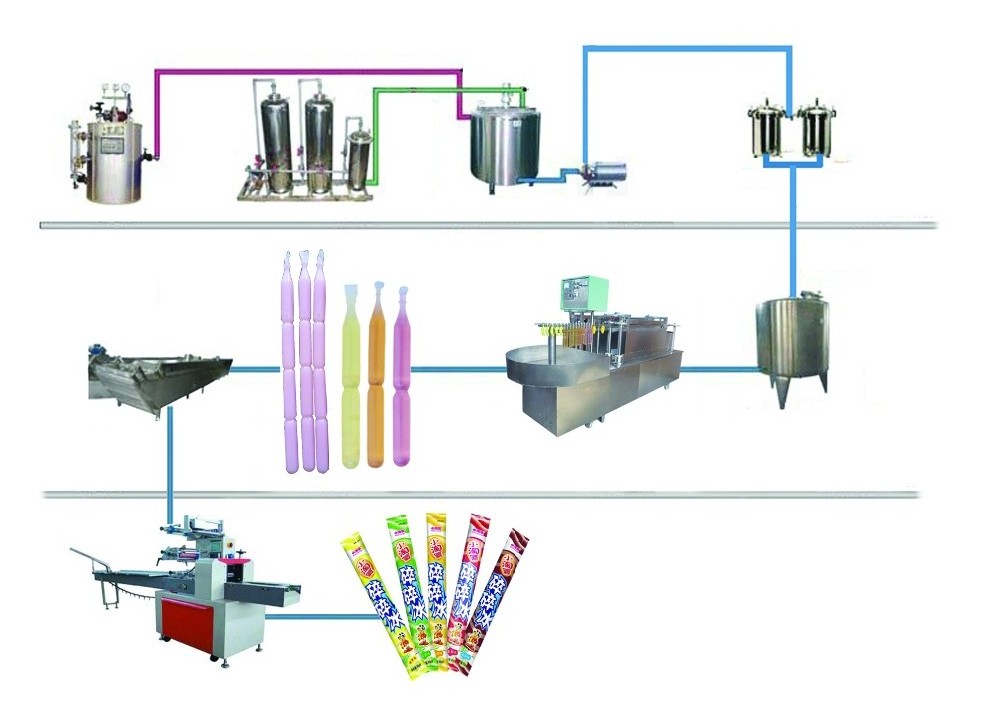

Product Description

It can be equipped with multiple filling heads, and the commonly used models are single-head machine, double-head machine and four-head machine. Automatic detection, no bottle without filling, injection filling, metering without adjustment, less overflow rate, no air bubbles. 316 stainless steel magnetic gear pump, long life, in line with food hygiene requirements. The continuously variable transmission system is adopted to adjust the production speed. This machine automatically completes filling, sealing and blanking at one time.

An ice pop filling machine is a mechanized system designed to fill ice pop molds or sleeves with liquid or pureed ingredients to create frozen treats. The machine typically consists of a conveyor belt or rotary system that moves the molds or sleeves along a production line. The process starts with the empty molds or sleeves being loaded onto the machine. The liquid or pureed ingredients are prepared separately and stored in a reservoir or hopper connected to the machine. When the machine is activated, the liquid or puree is dispensed into each mold or sleeve through individual nozzles or a continuous flow system. The volume of filling can be adjusted according to the desired size of the ice pop. Once filled, the molds or sleeves are moved to the next station on the conveyor belt or rotary system, where they are sealed using a heat sealing or mechanical sealing mechanism. After sealing, the ice pops are transferred to a freezing chamber or conveyor, where they are rapidly frozen to create a solid, ready-to-eat frozen treat. Ice pop filling machines are commonly used in commercial ice pop production facilities to automate the process and increase efficiency. They can handle high volumes of production, ensuring consistent filling and sealing of ice pops at a faster rate compared to manual filling methods.

Application

Specification

|

Filling Capacity

|

5000-15000pcs/hr

|

|

Filling Range

|

10-300ml(Customized)

|

|

Power

|

5kw

|

|

Voltage

|

220v,380v/50hz

|

|

Weight

|

500kgs

|

|

Machinery size

|

3000x710x1700mm

|

Packing & Delivery

wooden case

Hot Searches