- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Model Number:

-

HDPE Q 5502BN

-

Melt index:

-

0.35g/10min

-

Density:

-

0.955 G/cm3

-

Product name:

-

Virgin HDPE Resin Granules

-

Processing Methods:

-

Blow molding

-

Type:

-

Vrigin

-

Package:

-

25kg/bag

-

Keywords:

-

Virgin High Density Polyethylene

Quick Details

-

color:

-

Transparent white

-

Shape:

-

Granules, Granuels

-

Feature:

-

High stiffness, Good moldability, Good processability, Ethylene-hexene copolymer, Stress crack resistance

-

Place of Origin:

-

China

-

Model Number:

-

HDPE Q 5502BN

-

Melt index:

-

0.35g/10min

-

Density:

-

0.955 G/cm3

-

Product name:

-

Virgin HDPE Resin Granules

-

Processing Methods:

-

Blow molding

-

Type:

-

Vrigin

-

Package:

-

25kg/bag

-

Keywords:

-

Virgin High Density Polyethylene

Products Description

HDPE High Density Polyethylene, also known as Low Pressure Polyethylene, is a thermoplastic resin with high crystallinity and non polarity. The appearance of HDPE in its original state is milky white, with a certain degree of translucency in its thin cross-section. PE has excellent resistance to most living and industrial chemicals.

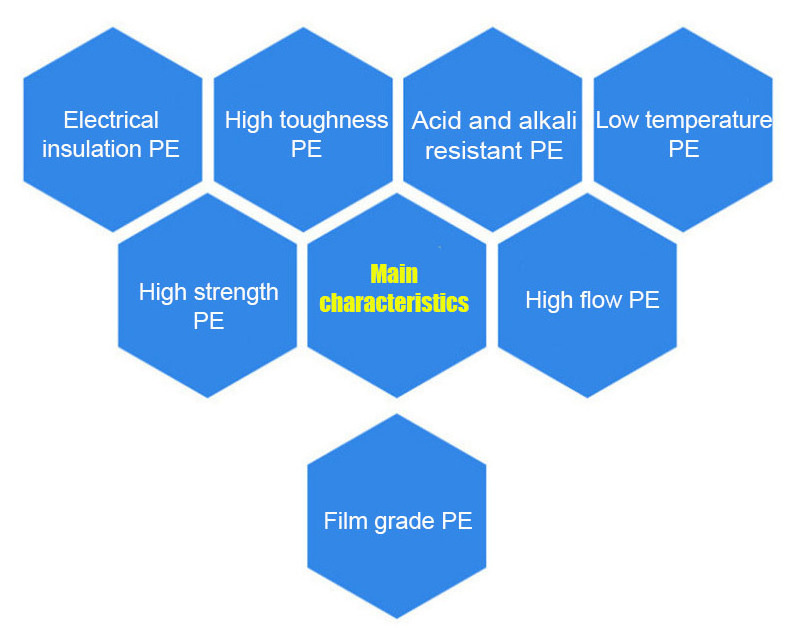

Advantages of HDPE plastic:

Acid and alkali resistant, organic solvent resistant, excellent electrical insulation, and able to maintain a certain degree of

toughness at low temperatures. The mechanical strength such as surface hardness, tensile strength, and rigidity are higher than LDPE, close to PP, and more ductile than PP, but the surface smoothness is not as good as PP

Acid and alkali resistant, organic solvent resistant, excellent electrical insulation, and able to maintain a certain degree of

toughness at low temperatures. The mechanical strength such as surface hardness, tensile strength, and rigidity are higher than LDPE, close to PP, and more ductile than PP, but the surface smoothness is not as good as PP

|

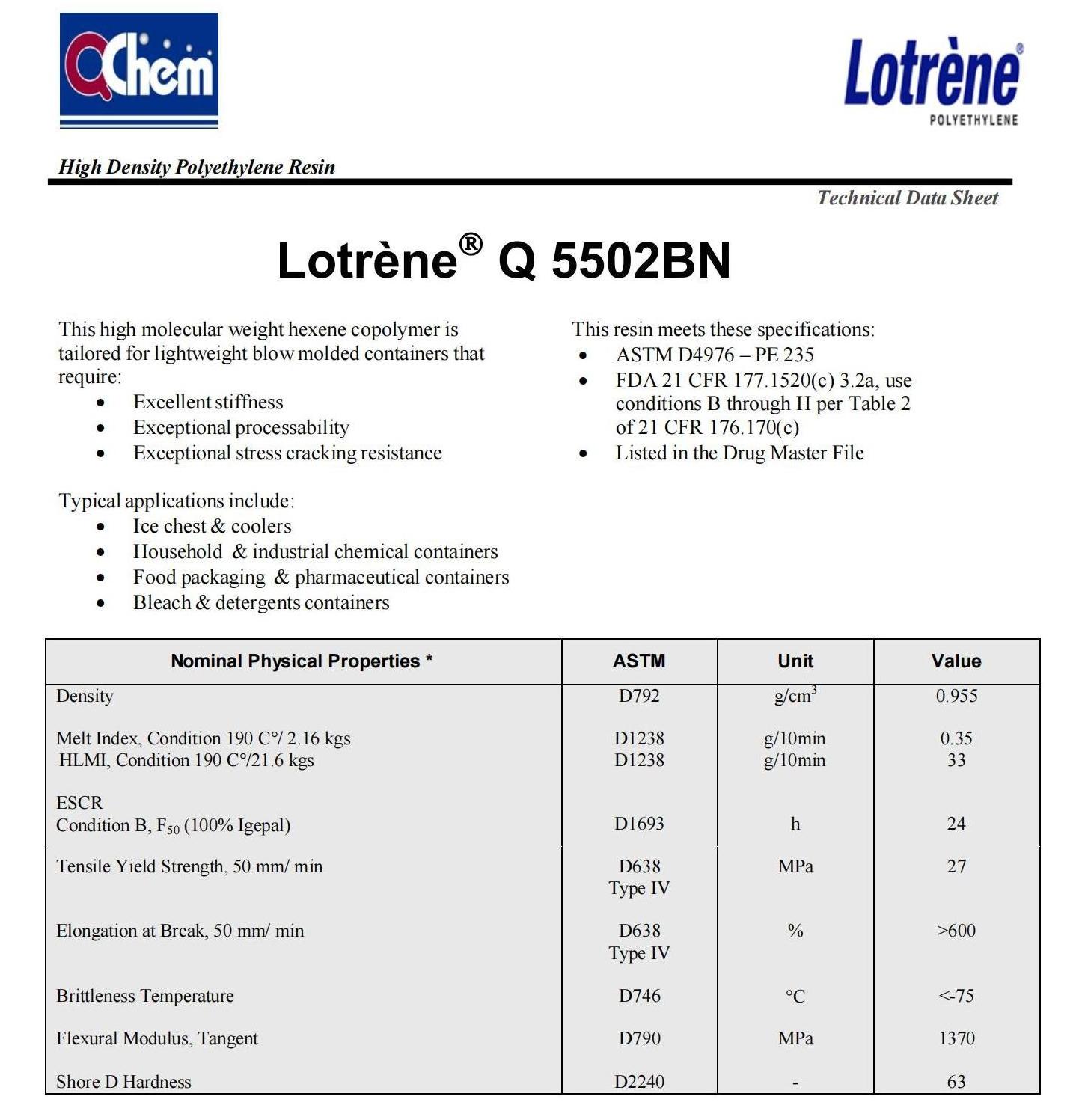

Product name

|

Lotrène® HDPE Q 5502BN

|

|

Process mothod

|

Blow molding

|

|

Features

|

High stiffness ,Stress crack resistance ,Good moldability,Good processability, Ethylene-hexene copolymer

|

|

Applications

|

Bleach bottle ,Blown containers Containers , Detergent bottle,Food packaging application,Pharmaceutical container ,Cooler boxes, Household chemicals container,Industrial chemicals container

|

|

Material Attribute

|

Blowing grade Food Contact grade C6

|

|

Package

|

25kg per bag

|

|

Model number

|

HDPE Q 5502BN,HDPE Q 50100, HDPE Q TR-144,

|

Details Images

Product Paramenters

|

Qatar HDPE

|

|

|

|

|||

|

Model

|

Density

23℃ |

Melt Index

190℃ 2.16kg |

Application

|

|||

|

HDPE Q 5502BN

|

0.955

|

0.35

|

Bleach bottle ,Blown containers Containers , Detergent bottle,Food packaging application,

Pharmaceutical container ,Cooler boxes,

Household chemicals container,Industrial chemicals containe |

|||

|

HDPE Q 50100,

|

0.948

|

0.06

|

Fuel tanks,Automotive dunnage,Truck-bed liner ,

Pallets,Chemical tanks,Agricultural tanks ,Boats,Large part blow molding ,Shipping containers,Thermoformed parts

|

|||

|

HDPE Q TR-144

|

0.946

|

0.18

|

Shopping bag,T-Shirt bags ,Trash bag ,Film ,Multi-wall liners

|

|||

Applications

The main uses of high-density polyethylene:

1. Injection molded products: There are turnover boxes, bottle caps, barrels, hats, food containers, trays, trash cans, boxes,and plastic flowers.

2. Blow molded products: Hollow shaped products, such as various series of blow molded barrels, containers, bottles, containers for storing cleaning agents, chemicals, cosmetics, gasoline tanks, daily necessities, etc. There are also blown film products, such as food packaging bags, miscellaneous shopping bags, fertilizer lining films, etc

3. Extruded products: Pipes and fittings are mainly used for gas transportation, public water and chemical transportation, such as building materials drainage pipes, gas pipes, hot water pipes, etc. Sheet materials are mainly used for seats, suitcases,handling containers, etc.

4. Rotary molding: Injection molded products such as large containers, storage tanks, barrels, boxes, etc.

5. Polyethylene can be processed into films , wire and cable sheaths, pipes, various hollow products, injection molded products,fibers, etc. Widely used in agriculture, packaging, electronics, machinery, automobiles, daily necessities, and other fields.

1. Injection molded products: There are turnover boxes, bottle caps, barrels, hats, food containers, trays, trash cans, boxes,and plastic flowers.

2. Blow molded products: Hollow shaped products, such as various series of blow molded barrels, containers, bottles, containers for storing cleaning agents, chemicals, cosmetics, gasoline tanks, daily necessities, etc. There are also blown film products, such as food packaging bags, miscellaneous shopping bags, fertilizer lining films, etc

3. Extruded products: Pipes and fittings are mainly used for gas transportation, public water and chemical transportation, such as building materials drainage pipes, gas pipes, hot water pipes, etc. Sheet materials are mainly used for seats, suitcases,handling containers, etc.

4. Rotary molding: Injection molded products such as large containers, storage tanks, barrels, boxes, etc.

5. Polyethylene can be processed into films , wire and cable sheaths, pipes, various hollow products, injection molded products,fibers, etc. Widely used in agriculture, packaging, electronics, machinery, automobiles, daily necessities, and other fields.

Packing and shipping

Usually 25kg/bag, 1 ton in 1 pallet

Certifications

Hot Searches