G

et to

K

now the

E

vaporator

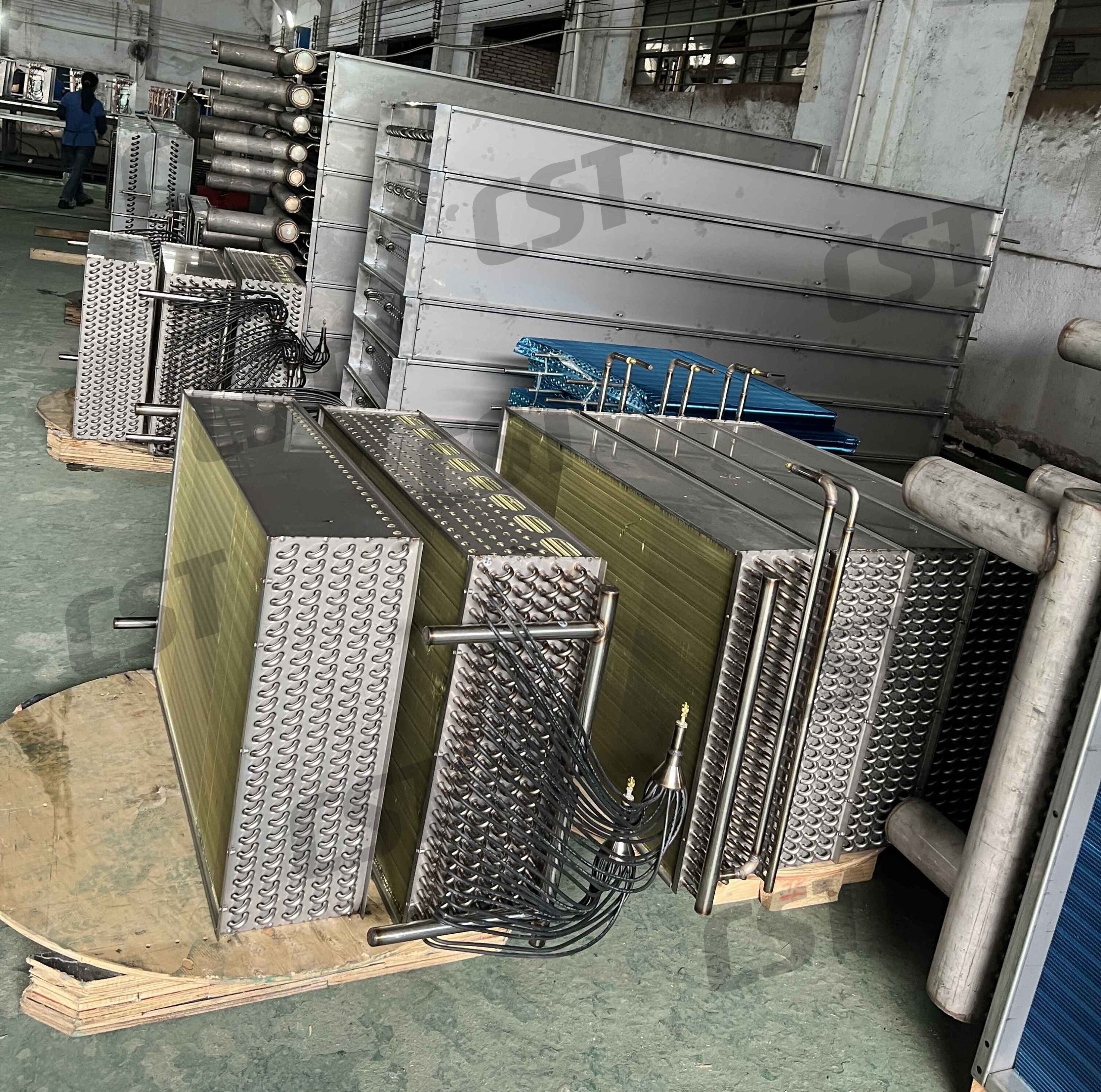

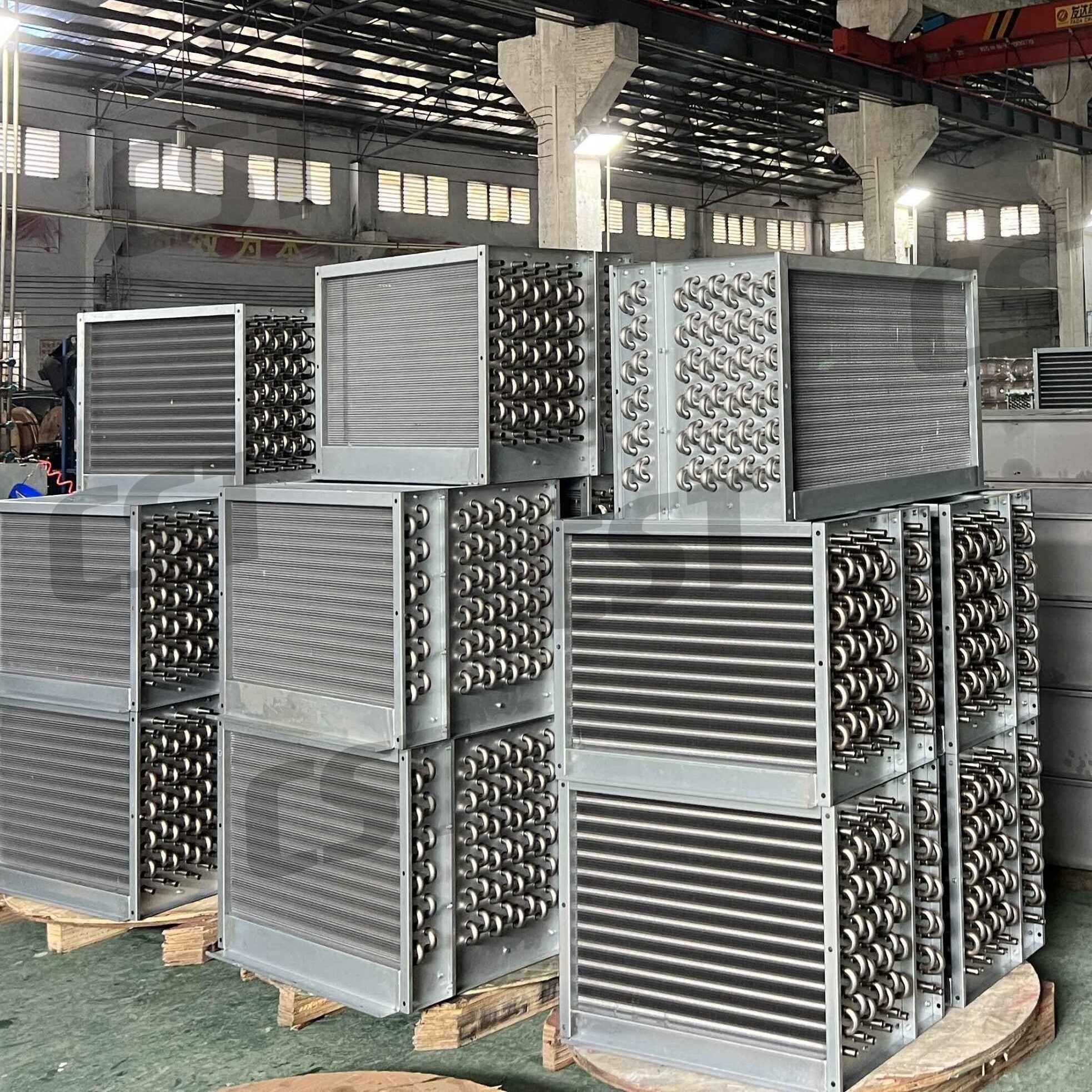

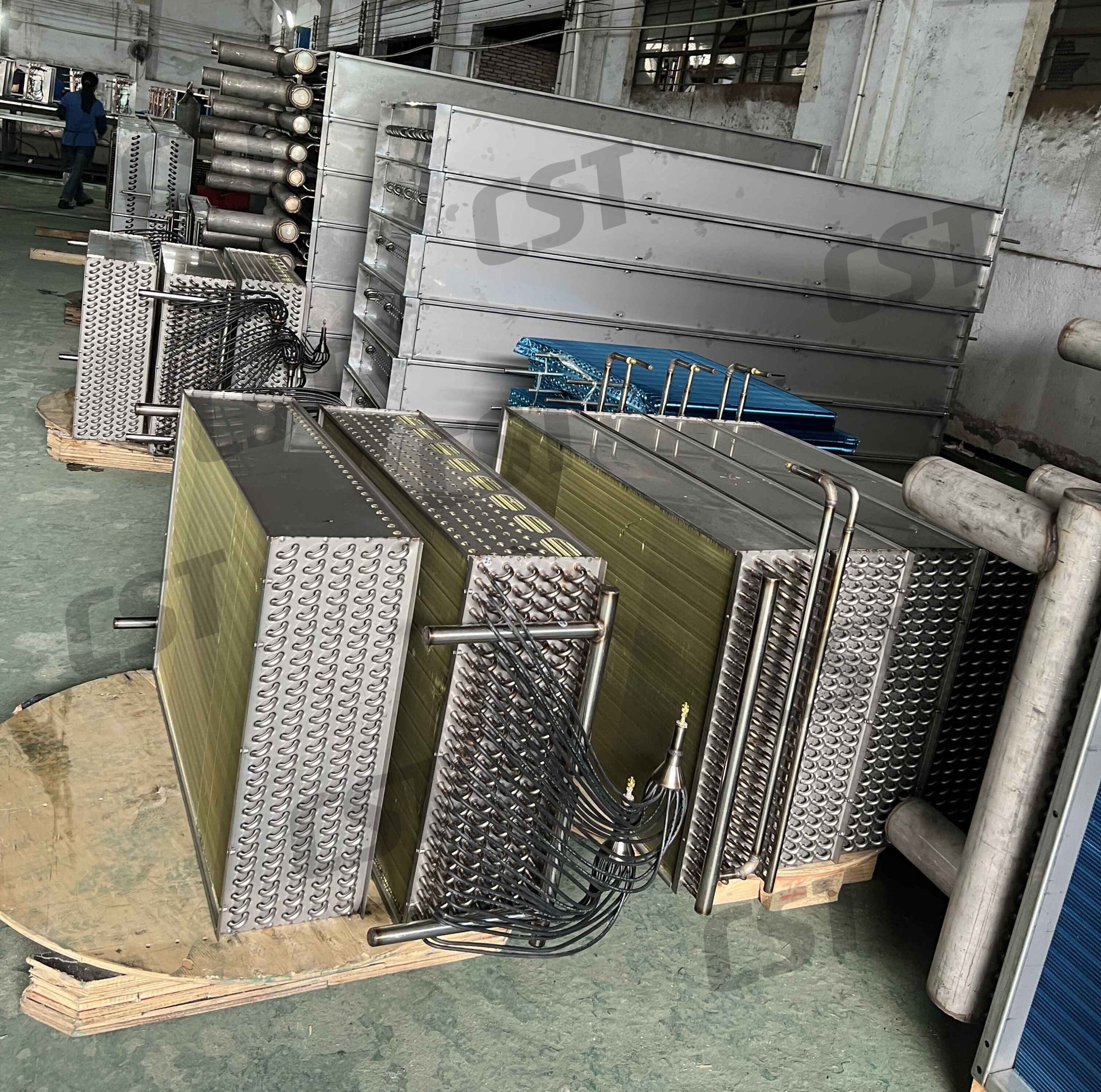

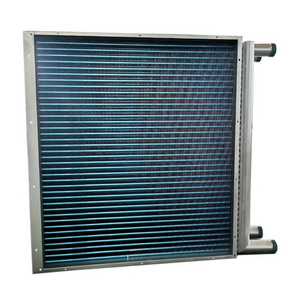

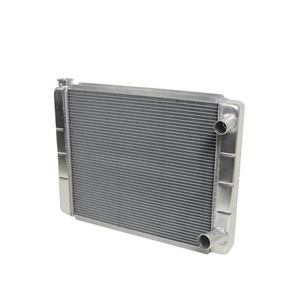

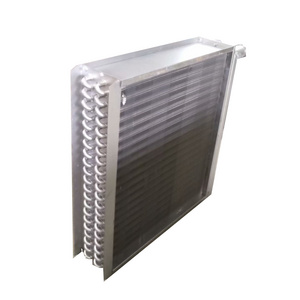

* The heat transfer efficiency is higher than that of the fin's disturbance to the fluid, which causes the boundary layer to break continuously, thus having a larger heat transfer coefficient; at the same time, because the baffles and fins are very thin and have high thermal conductivity, the tube-fin heat exchanger can be Achieve high efficiency.

* Compact Because the tube-fin heat exchanger has an extended secondary surface, its surface area can reach 1000m³

* The reason for the light weight is that it is compact and mostly made of aluminum alloy. Now steel, copper, composite materials, etc. have also been mass-produced.

*Adapted to strong tube-fin heat exchangers can be applied to: heat exchange between gas-gas, gas-liquid, liquid-liquid, various fluids, and phase-change heat that undergoes concentration changes. It can adapt to different heat transfer conditions such as counter flow, cross flow, multi-stream flow, multi-pass flow, etc. through the unknown and combination of flow. The combination of series, parallel, and series-parallel between the units can meet the heat exchange needs of large-scale equipment. Industrially, it can be shaped and mass-produced to reduce costs, and interchangeability can be expanded through modular combination.

*The manufacturing process requires strict and complex process. It is easy to block, not resistant to corrosion, and difficult to clean and repair, so it can only be used where the heat exchange medium is clean, non-corrosive, not easy to scale, not easy to deposit, and not easy to block.