Capacity:Max.10 Ton(Optional 5Ton\8 Ton\\15 Ton or as requirement) Hydraulic system expand coil inner hole,Dual oil cylinder, cylinder diameter 90mm, stroke 240mmm,

Car travel: height travel 400mm, length travel 2.5m, Frequency Inverter to regulate turning speed Link-connect expanding system,Coil Inner-Diameter:450-510mm,

Coil width:1000-1650mm, Automatic stopping device with limited switch as assistance to control stop/start rotation

- Product Details

- {{item.text}}

Quick Details

-

No. of Slitting Lines:

-

2 - 20

-

Marketing Type:

-

Coil Slitting Machine

-

Coil Weight (T):

-

20 T

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WADLEY

-

Voltage:

-

380V 50HZ 3Phase or based on customer's need

-

Rated Power:

-

7.5KW

-

Weight:

-

10000

-

Feeding width (mm):

-

1000-1200MM

-

Frame material:

-

350H

-

Box thickness:

-

16mm

-

Protection grade:

-

IP55

-

Motor explosion-proof level:

-

ExdIICT4

-

Motor ratio:

-

4:43

-

Control system:

-

Tricrystal

-

slitting quantity:

-

as customers requirement

-

Coil width:

-

as customers requirement

-

Function:

-

Slitting/leveling/cutting

Quick Details

-

Cutting Width (mm):

-

50 - 10000 mm

-

Material Thickness(mm):

-

0.3 - 2 mm

-

Cutting Speed(m/min):

-

200 - 1000 mm

-

No. of Slitting Lines:

-

2 - 20

-

Marketing Type:

-

Coil Slitting Machine

-

Coil Weight (T):

-

20 T

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WADLEY

-

Voltage:

-

380V 50HZ 3Phase or based on customer's need

-

Rated Power:

-

7.5KW

-

Weight:

-

10000

-

Feeding width (mm):

-

1000-1200MM

-

Frame material:

-

350H

-

Box thickness:

-

16mm

-

Protection grade:

-

IP55

-

Motor explosion-proof level:

-

ExdIICT4

-

Motor ratio:

-

4:43

-

Control system:

-

Tricrystal

-

slitting quantity:

-

as customers requirement

-

Coil width:

-

as customers requirement

-

Function:

-

Slitting/leveling/cutting

Product Description

Advantage Of

Automatic Metal Color Steel Sheet Coil Slitting Machine Production Line:

1. This machine adopts PLC control, easy to operate, reliable performance and beautiful appearance. Set the parameters on the PLC control cabinet, the machine automatically leveling and cutting, easy to operate and save labor cost. The leveling and shearing machine cuts metal plates at fixed lengths according to customer requirements. Set the length on the Plc, and the calibrating and shearing machine cuts automatically, saving labor cost.

2. Maintain the sheet flat feed, the surface of the sheared sheet is smooth without scratches, the cut is flat, no falling

material, saving material cost.

3. The slitting roller adopts Cr12Mov, heat treatment, durable material, smooth cut of the slitted sheet.

4. The laminating device can be added according to customers' requirements With push-pull grid guard above the main machine to protect the safety of employees.

2. Maintain the sheet flat feed, the surface of the sheared sheet is smooth without scratches, the cut is flat, no falling

material, saving material cost.

3. The slitting roller adopts Cr12Mov, heat treatment, durable material, smooth cut of the slitted sheet.

4. The laminating device can be added according to customers' requirements With push-pull grid guard above the main machine to protect the safety of employees.

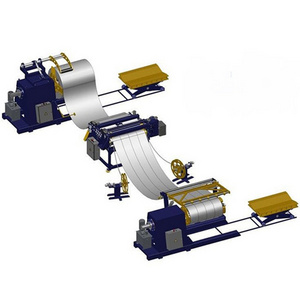

The production flow of

Automatic Metal Color Steel Sheet Coil Slitting Machine Production Line:

Coil loading car----Decoiler----center aligner-----slitting machine--levelling system--waste scrap winder- --pre-separator--tensioner---pressing separator--recoiler--manual packing-Unloading coil car

Specification

|

item

|

value

|

|

Cutting Width (mm)

|

50mm - 10000mm

|

|

Material Thickness(mm)

|

0.3mm - 2mm

|

|

Cutting Speed(m/min)

|

200mm - 1000mm

|

|

Coil Weight (T)

|

10-20T

|

|

Voltage

|

380V 50HZ 3Phase or based on customer's need

|

|

Rated Power

|

11KW

|

|

Weight

|

10000

|

|

Frame material

|

350H

|

|

Box thickness

|

16mm

|

|

Protection grade

|

IP55

|

|

Motor explosion-proof level

|

ExdIICT4

|

|

Motor ratio

|

4:43

|

|

Control system

|

Tricrystal

|

|

slitting quantity

|

as customers requirement

|

|

Coil width

|

as customers requirement

|

Machine Parts Detail

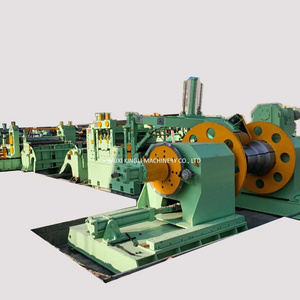

1.Hydraulic Decoiler:

2.Slitting Syetem

.

Shaft diameter: 120 solid shaft

Chain: Double 2-inchThe lower blade shaft is finely processed through multiple processes such as turning, high-frequency processing, precision grinding, chrome plating, It can make the cut panel flat and burr free, with high precision,The number of slits can be changed according to customer needs.

Chain: Double 2-inchThe lower blade shaft is finely processed through multiple processes such as turning, high-frequency processing, precision grinding, chrome plating, It can make the cut panel flat and burr free, with high precision,The number of slits can be changed according to customer needs.

3.Leveling system

.

Main shaft:120 solid shaftHydraulic pump station:5.5KW

The expansion coil adopts hydraulic control, which is convenient, fast, and stable.

The expansion coil adopts hydraulic control, which is convenient, fast, and stable.

4.Recoiler system

.

It consists of a material distribution device, a reduction device, a hydraulic expansion device, a pushing device, and a

transmission device. It can ensure that the numerous small strips after cutting are neatly wound.

transmission device. It can ensure that the numerous small strips after cutting are neatly wound.

5. Packaging

All accessories will be placed in a cardboard box and placed in the electrical control cabinet of the machine. All equipment and electrical components will be wrapped with industrial cling film to ensure that they are floating and damp at sea. The cabinet and equipment will be fixed with 1.5 diameter iron wire to ensure that all equipment safely reaches every customer's hand。

Hot Searches