- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1800 KG

-

Place of Origin:

-

China

-

Name:

-

Automatic Edge Banding Machine

-

Material:

-

Wood MDF Material

-

Voltage:

-

220v/380v

-

Power:

-

11kw

-

Dimension:

-

4417*830*1610mm

-

Key words:

-

Wood Processing Equipment

-

Raw material:

-

Wood Material

-

Function:

-

Multifunctional

-

Panel Thickness:

-

10-60mm

-

Speed:

-

4000-6000piece/hour

Quick Details

-

Machinery Capacity:

-

16m/,min

-

Brand Name:

-

CAMEL CNC

-

Year:

-

2022

-

Weight:

-

1800 KG

-

Place of Origin:

-

China

-

Name:

-

Automatic Edge Banding Machine

-

Material:

-

Wood MDF Material

-

Voltage:

-

220v/380v

-

Power:

-

11kw

-

Dimension:

-

4417*830*1610mm

-

Key words:

-

Wood Processing Equipment

-

Raw material:

-

Wood Material

-

Function:

-

Multifunctional

-

Panel Thickness:

-

10-60mm

-

Speed:

-

4000-6000piece/hour

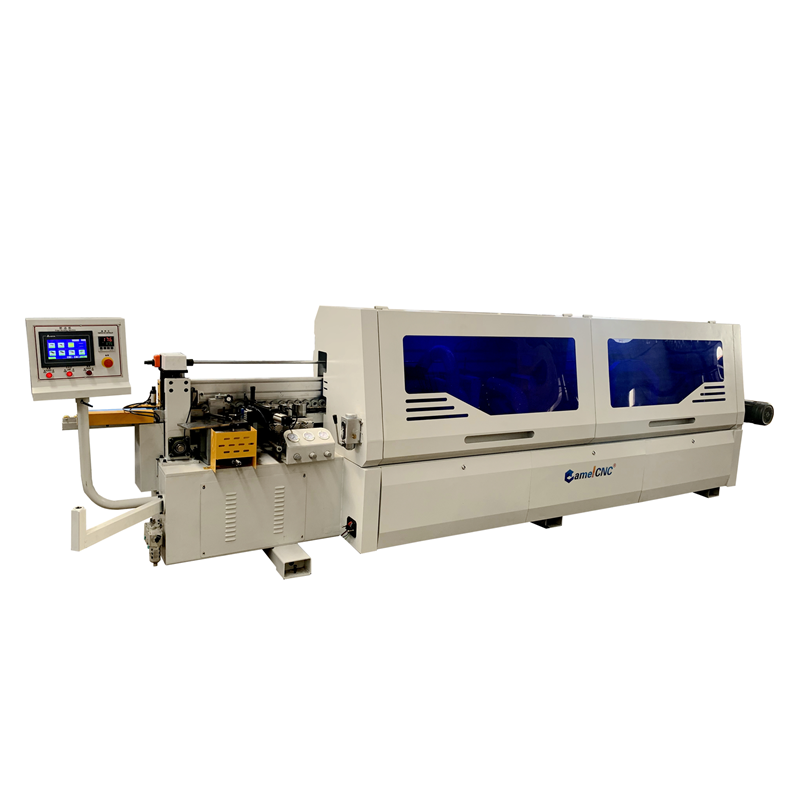

CA-368 Automatic Pvc Mdf Cnc Edge Banding Machine Board Cutting And Edging Woodworking Edge Bander

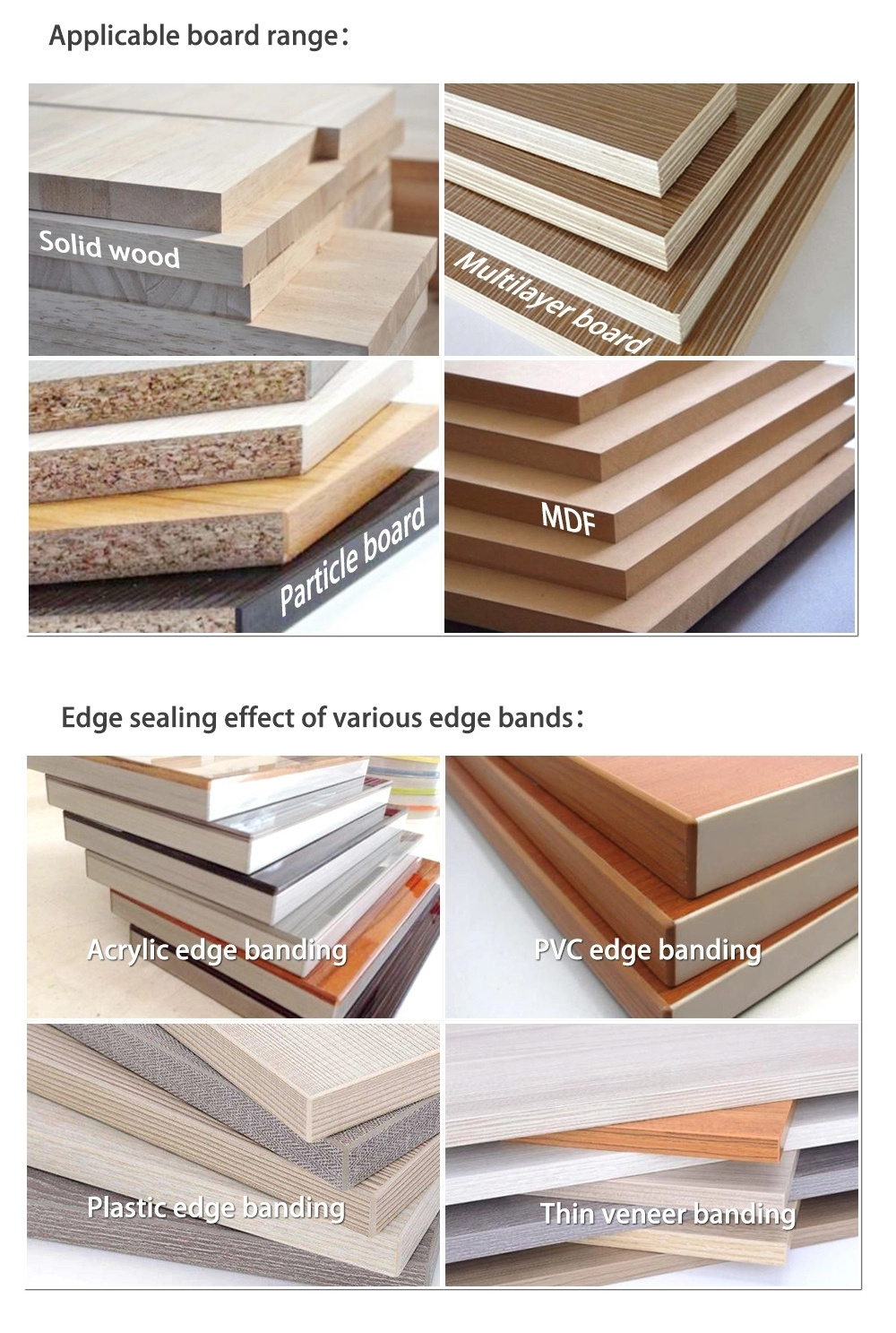

It is suitable for straight edge sealing of solid wood board, fiberboard, particle board and other board workpieces. The edge sealing materials can be solid wood strips, PVC, melamine, veneer, etc.

1. Equipped with an exquisite thermometer, it is sensitive to temperature and provides accurate heating temperature in real time.

2. Overvoltage and undervoltage circuit protection, effectively protect the electronic components of the equipment, and remind customers to provide stable working power.

3. The effect of the edge banding machine is high precision and high efficiency.

4. The End-cutting device moves through precise linear guides, adopts the structure of automatic tracking of the mold and fast cutting of high-frequency high-speed motor, etc., to ensure that the cut surface is smooth and smooth.

It can be equipped with a double glue pot pressing and sticking system, which can quickly switch between two colors of glue, and reduce the visibility of the glue line.

Technical Data:

|

Edge band thickness |

0.3-3mm |

|

Sheet workpiece thickness |

10 -60mm |

|

conveyor belt speed |

16 m /min |

|

Minimum width of sheet |

45 mm |

|

Minimum length of sheet |

70mm |

|

Total Power |

7 kw |

|

working pressure |

0.6Mpa |

|

Voltage |

380v/,50/60hz |

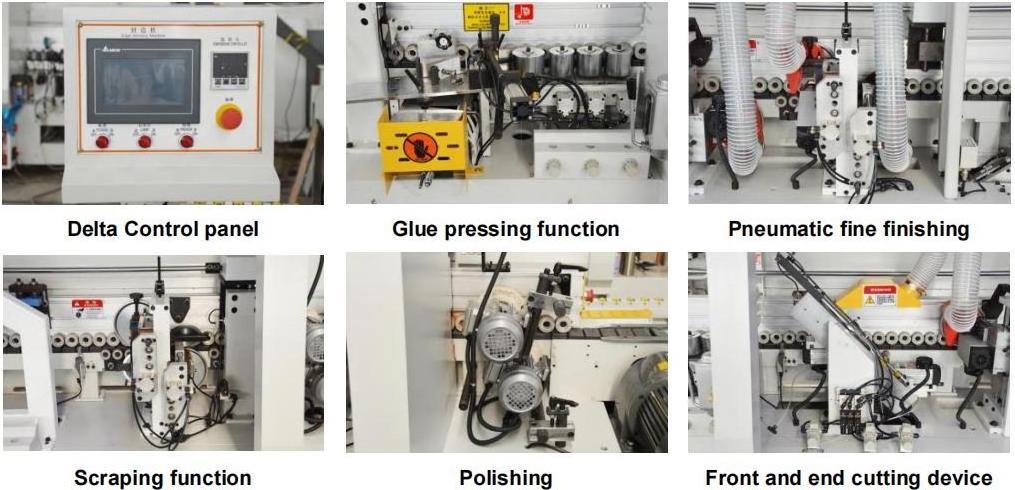

Machine Details:

Questions:

Can i get some advice? or How can I get a free training?

Answer:

Click here, we will send the related details to you

.

Service& Support:

CAMEL CNC provides three types of After-Sales service:Hot-line support,Email-support,and On-Site Machine installation.You could choose any type for your convenience details as below:

1 ,After receiving machine clients could install in guide of video and instructions provided.

2, lf you have any question during installation or operation,we will assist via Skype.Whatsapp.Teamviewer or other tools online until clients can operate machine skilfully.

3 ,If client needs,we could provide sample drawings for testing.

4 ,lf clients need on-site installation and training we will charge $200per day as well as round train costs for sending technician and local Accommodation or you could contact your sales manager for discussing details.

5, Our company will contact clients on machine working status feedback new requirements or good suggestions regularly and revert back to our company functional departments to improve our machines or service.