- Product Details

- {{item.text}}

Quick Details

-

Spangle Type:

-

Zero Spangle

-

Hardness:

-

Full Hard

-

Place of Origin:

-

American Samoa

-

Brand Name:

-

Sihua

-

Length:

-

2000-12000mm or customized

-

Grade:

-

DX51D

-

Product name:

-

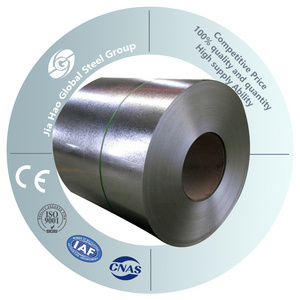

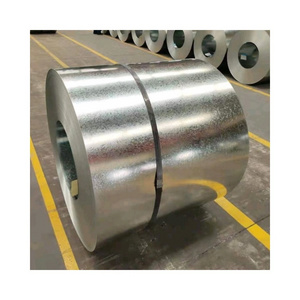

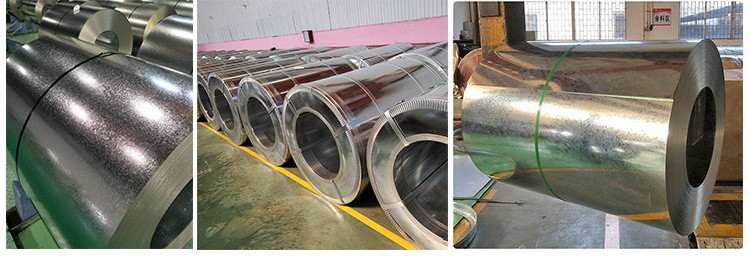

Galvanized coil

-

Material:

-

SGCC/DX51D/DX51D+Z

-

MOQ:

-

5 Tons

-

Spangle:

-

Big Medium Small Zero

-

Packing:

-

Standard Sea-worthy Packing

-

PAYMENT TERM:

-

30%T/T Advance + 70% Balance

-

Advantage:

-

Strong Corrosion Resistance

Quick Details

-

Type:

-

Steel Coil

-

Thickness:

-

0.11-1.2 mm

-

Coating:

-

Z181-Z275

-

Spangle Type:

-

Zero Spangle

-

Hardness:

-

Full Hard

-

Place of Origin:

-

American Samoa

-

Brand Name:

-

Sihua

-

Length:

-

2000-12000mm or customized

-

Grade:

-

DX51D

-

Product name:

-

Galvanized coil

-

Material:

-

SGCC/DX51D/DX51D+Z

-

MOQ:

-

5 Tons

-

Spangle:

-

Big Medium Small Zero

-

Packing:

-

Standard Sea-worthy Packing

-

PAYMENT TERM:

-

30%T/T Advance + 70% Balance

-

Advantage:

-

Strong Corrosion Resistance

Product Paramenters

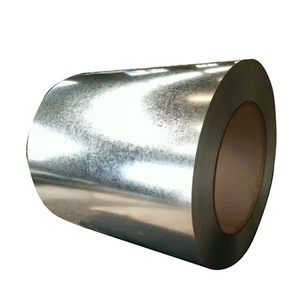

Hot-dip galvanizing is a process of coating steel with a layer of zinc to protect it from corrosion. The process involves

immersing the steel in a bath of molten zinc at a temperature of around 450°C, which results in a metallurgically bonded coating that is highly resistant to corrosion.

immersing the steel in a bath of molten zinc at a temperature of around 450°C, which results in a metallurgically bonded coating that is highly resistant to corrosion.

|

Technical Standard

|

EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653

|

|

Steel Grade

|

Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,

SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); or Customer’s Requirement |

|

Type

|

Coil/Sheet/Plate/Strip

|

|

Thickness

|

0.11-1.2mm,or customer's requirement

|

|

Width

|

600mm-1500mm, according to customer's requirement

|

|

Type of Coating

|

Hot dipped galvanized steel coil

|

|

Zinc Coating

|

30-275g/m2

|

|

Surface Treatment

|

Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U)

|

|

Surface Structure

|

Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS)

|

|

Package

|

Water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped by

seven steel belt.or according to customer's requirement. |

Product advantage

Our company

Sihua Steel Group Company Limited is a comprehensive enterprise group integrating steel product sales, after-sales service and domestic and international trade. The company implements ISO9001-2000 quality management system and ISO14001 environmental protection system, and has formed carbon steel and stainless steel products while actively developing diversification, covering pipes, profiles, plates, etc.

Through continuous expansion of production scale, adjustment and optimization of product structure, showing a trend of efficient and sustainable development. With excellent quality and excellent service, all products not only sell well in the domestic market for more than 30 years, but also exported to Russia, Canada, India, Brazil, Southeast Asia and other more than 40 countries and regions, enjoy a high reputation in the international market.

We guarantee complete specifications, timely delivery, superior quality and favorable price. Your unwavering support and growing demand will help us to offer a wider range of high quality products at more competitive prices. Win-win is our eternal pursuit.

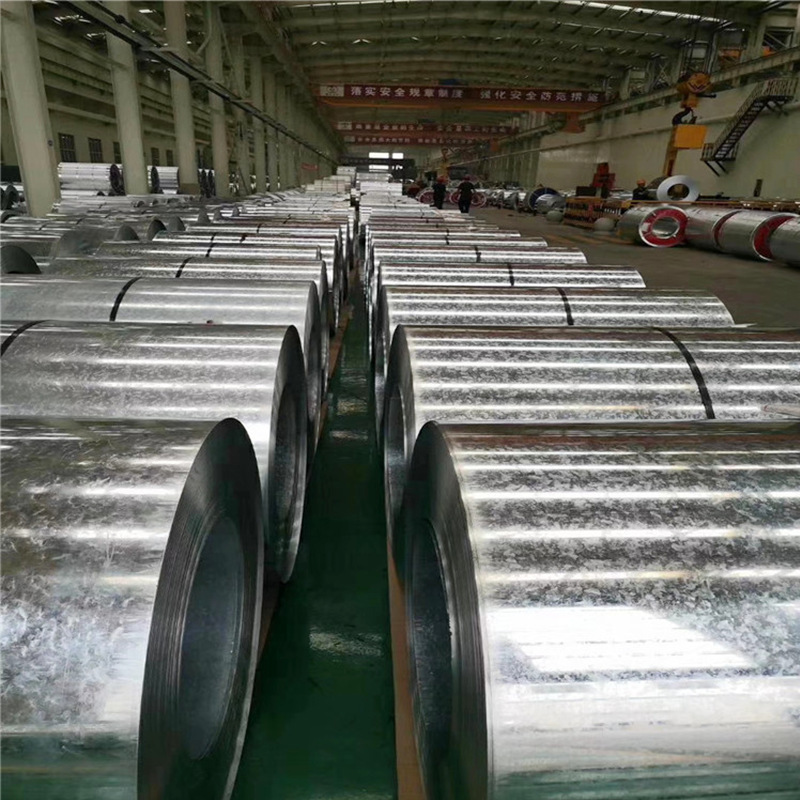

Factory production

Sihua-Quality Inspection

1.Our factory has its own "experimental testing center".CNAS Laboratory Accreditation Certificate (the second private enterprise to obtain this certificate)

2.Control quality strictly.The first pass is the quality inspection on the production line,The second pass is full inspection of

the production quality.

3.We have got internationally recognized certificates, ISO, CE, LR,Philippine certificate,also support third-party testing,as

SGS,BV, ect.

2.Control quality strictly.The first pass is the quality inspection on the production line,The second pass is full inspection of

the production quality.

3.We have got internationally recognized certificates, ISO, CE, LR,Philippine certificate,also support third-party testing,as

SGS,BV, ect.

Product packaging

Good reputation

Customer Photos

Certifications

FAQ

Q: Do you have an after-sales team? Do you have a research and development team?

A: We have a professional after-sales team and a research and development team of 3-5 people.

Q: Can you send me a product catalog?

A: Yes, please leave your contact information and I will send you the latest catalog.

Q: How can I get the most favorable price?

A: Please send us the details of the product,such as material grade, size, etc. Then we will quote you the most favorable price accordingly.

Q: How long is your delivery time?

A: We have ten thousand tons of spot inventory. The delivery time is usually around 3-5 days.

A: We have ten thousand tons of spot inventory. The delivery time is usually around 3-5 days.

Q: How many years have your company been producing this product?

A: We have been in this industry for 15 years, so we can provide you with the most favorable prices and professional services.

Q: What kind of processing can your company do?

A: The batching process involves laser edge grinding,polishing, mechanical processing, inspection of castings, sawing, cutting, surface inspection, drilling, drilling, pressing,forming, grinding, machine edge grinding, packaging, grinding, polishing, and casting. After cleaning, manual edge grinding,packaging, warehousing, electroplating, heat treatment, cutting, and planing.

Hot Searches