- Product Details

- {{item.text}}

Quick Details

-

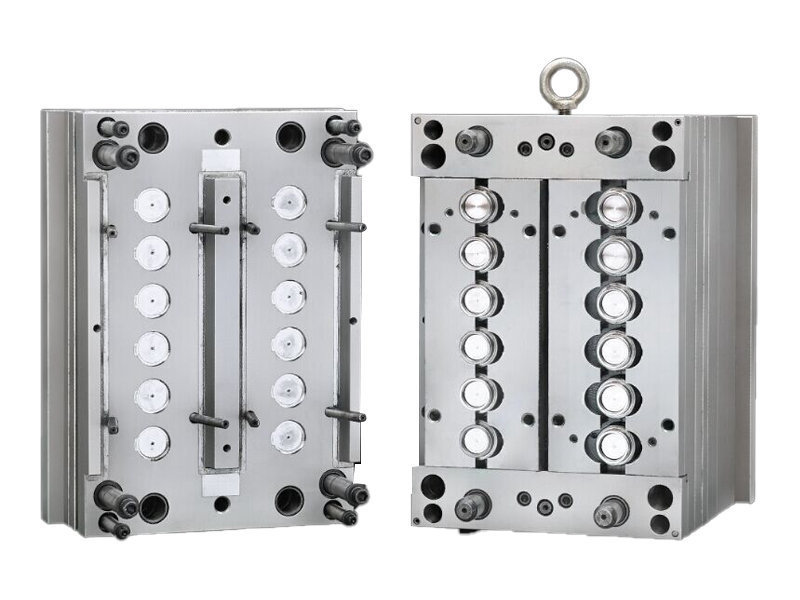

Model Number:

-

M-20L

-

Material:

-

S136

-

Usage:

-

injection molding machine

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Mould Life:

-

more than 1,000,000 times

-

Product Name:

-

caps,lids,preforms,covers...

-

Runner:

-

Cold runner / hot runner

-

Samples:

-

Send according to customer's requirement

-

Logo:

-

Custom Logo Available

-

Processing Equipment:

-

CNC, Lathe, EDM, Wire Cutting, Drilling, etc

-

Mould Material:

-

Aluminum, P20, Steel, S136H...

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

zoepack

-

Model Number:

-

M-20L

-

Material:

-

S136

-

Usage:

-

injection molding machine

-

Cavity:

-

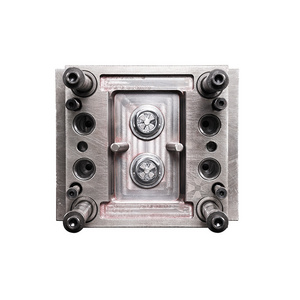

Single Cavity\ Multiple Cavity

-

Mould Life:

-

more than 1,000,000 times

-

Product Name:

-

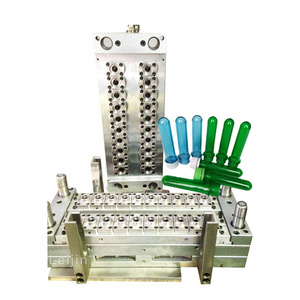

caps,lids,preforms,covers...

-

Runner:

-

Cold runner / hot runner

-

Samples:

-

Send according to customer's requirement

-

Logo:

-

Custom Logo Available

-

Processing Equipment:

-

CNC, Lathe, EDM, Wire Cutting, Drilling, etc

-

Mould Material:

-

Aluminum, P20, Steel, S136H...

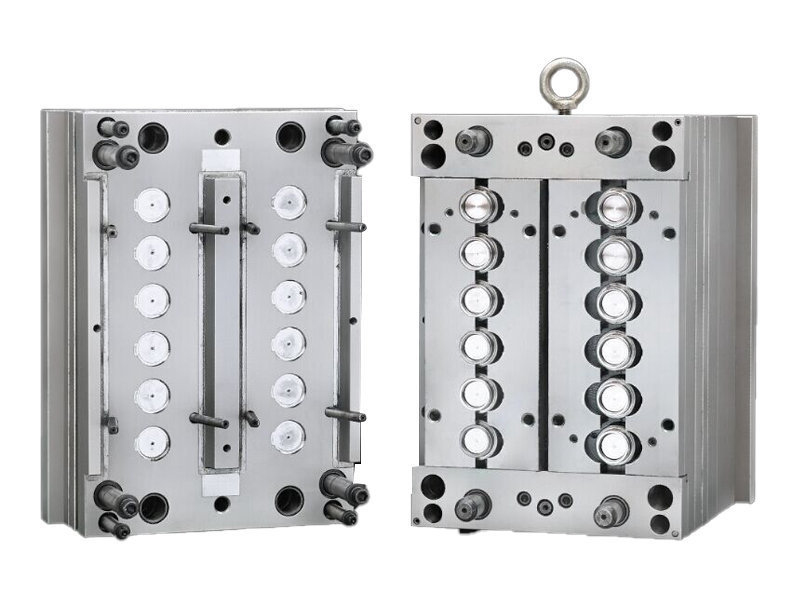

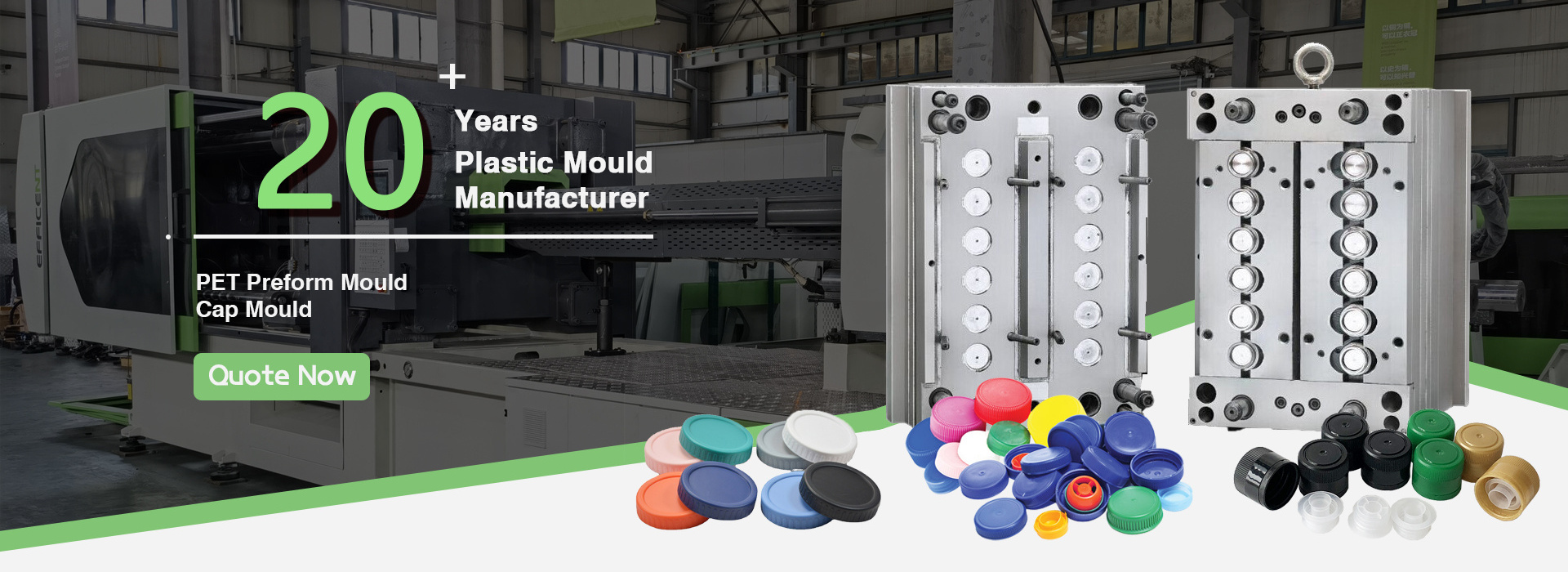

***Plastic PET Preform & Cap Mould EXPERT***

Our customers are all around the world.

Vietnam, Australia, Indonesia, Malaysia, Thailand, Sri Lanka, Kazakhstan, Russia, UAE, Saudi Arabia, Malta, Romania, Italy, India,Syria, Ethiopia, Egypt, Sudan, Tunisia, Algeria, Kenya, Nigeria, South Africa, Zimbabwe, Mexico, Guatemala, Ecuador, Colombia,Venezuela, Peru....

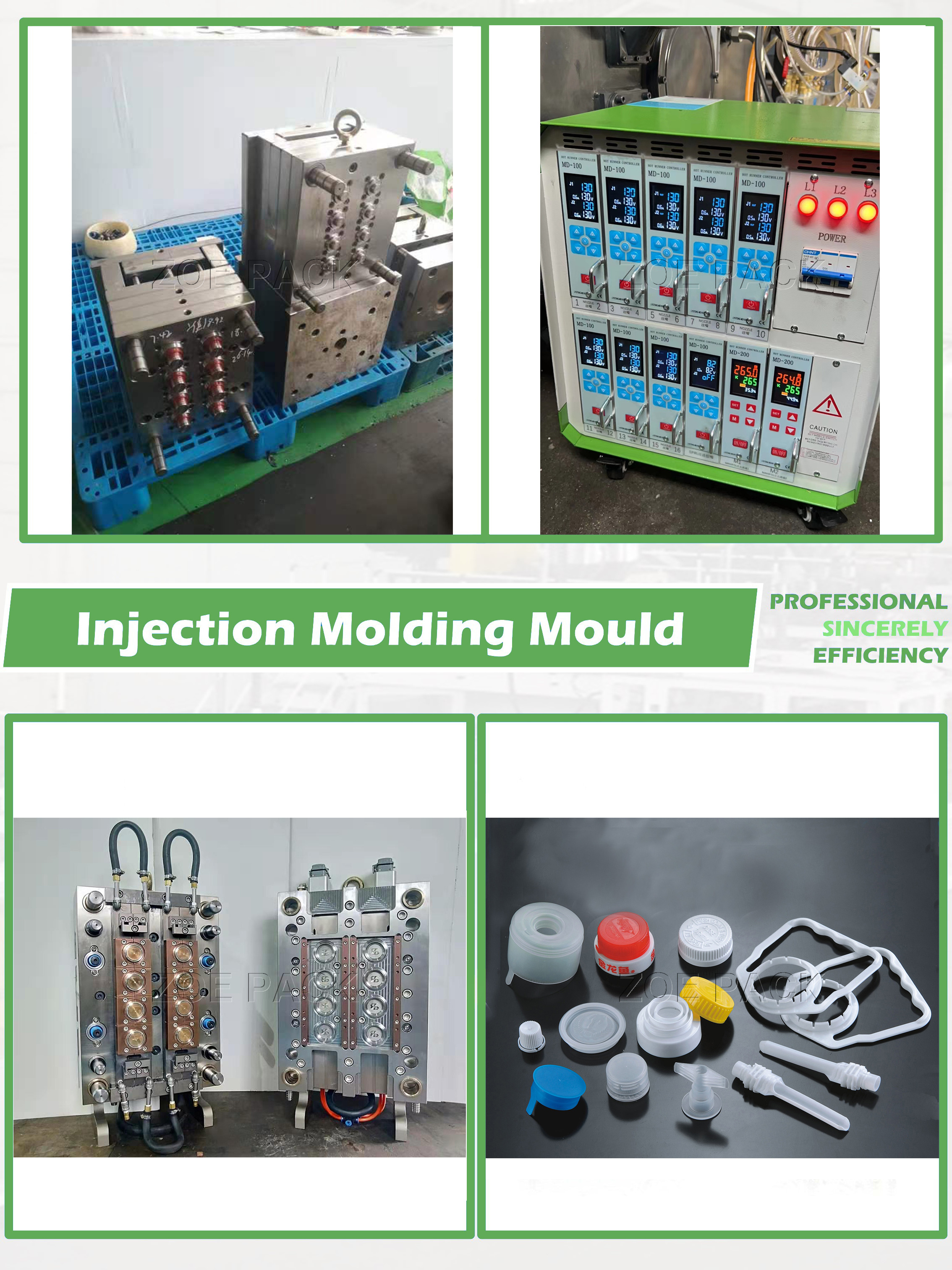

Details Images

|

QUALITY First

|

|

|

|

|

||||

|

1. Mould cavity & Cutting edges use high quality Stainless steel

S136H

, which is the best material for blowing moulds.

|

|

|

|

|

||||

|

2. Our necking plate is using imported JAPAN material DC53,Heat treatment to HRC62.

|

|

|

|

|

||||

|

3. Our cooling system is covered very average,all the necking area, handle area had designed perfect cooling system to make sure long time smooth running.

|

|

|

|

|

||||

|

4. Our de-flashing unit and mask material is using High quality Aluminium alloy 6061#.

|

|

|

|

|

||||

|

5. De-flashing cylinder all use high quality Taiwan AIRTAC cylinder.

|

|

|

|

|

||||

CORE

Hardness: 50-52HRC

Marterial:S136 / P20

Big cooling water road design ,Ensure preform have good cooling effect.

THREAD

Hardness: 50-52HRC

Marterial:S136 / P20

Independent cooling water is used. Add pin nails. Ensure high quality molding

NOZZLE HOLDER

Hardness: 53-55HRC

Material :SKD61

Why Choose Us

Advantages

ZOEPACK make PET preform mould and cap mould for many years. Our mould make preform finishing more smooth, due to our mould quality and precision finishing.So that can

let your preform quality more competitive in the market.

According to the demand of plastic product, we start produce some plastic products, too. So you are not only can looking for good quality mould form us, also can finding plastic product here.

Send us the inquiry with drawing and requirement (steel raw material, cavity no. etc) for mould, we will reply you within 24 hours and quote for you within 2 working days.

Let ZOEPACK be your reliable factory!

According to the demand of plastic product, we start produce some plastic products, too. So you are not only can looking for good quality mould form us, also can finding plastic product here.

Send us the inquiry with drawing and requirement (steel raw material, cavity no. etc) for mould, we will reply you within 24 hours and quote for you within 2 working days.

Let ZOEPACK be your reliable factory!

Some of our partners

Professional Workshop

Hot Searches