- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HEBEI FANGTAI

-

Application:

-

PET Bottle Recycling

-

Production Capacity (kg/h):

-

200 - 5000

-

Voltage:

-

380V or optional

-

Dimension(L*W*H):

-

50000*4000*4000mm

-

Power (kW):

-

180kw

-

Weight (T):

-

13

-

Applicable Industries:

-

pet bottle washing line, plastic recycling industry

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

PET Bottle Waste

-

Color:

-

optional

-

Capacity:

-

300-5000kg/h

-

Keywords:

-

pet bottle recycling plant

-

Certificate:

-

CE INTERTEK

-

Weight:

-

10-30tons

-

Motor brand:

-

Simens Beide or wannan

-

Power(W):

-

depend on the capacity

Quick Details

-

Machine Type:

-

PET Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

5000kg/H

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HEBEI FANGTAI

-

Application:

-

PET Bottle Recycling

-

Production Capacity (kg/h):

-

200 - 5000

-

Voltage:

-

380V or optional

-

Dimension(L*W*H):

-

50000*4000*4000mm

-

Power (kW):

-

180kw

-

Weight (T):

-

13

-

Applicable Industries:

-

pet bottle washing line, plastic recycling industry

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

PET Bottle Waste

-

Color:

-

optional

-

Capacity:

-

300-5000kg/h

-

Keywords:

-

pet bottle recycling plant

-

Certificate:

-

CE INTERTEK

-

Weight:

-

10-30tons

-

Motor brand:

-

Simens Beide or wannan

-

Power(W):

-

depend on the capacity

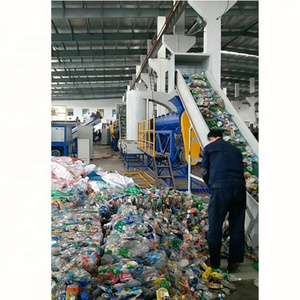

Introduce of pet bottle plastic recycling machine :

plastic pet bottle recycling machine/plastic recycling plant/pet bottle washing line is widely used to treat PET bottle and scrap PET plastic broken into flakes. It is a crushing, washing, drying line. With advanced international industry concepts and technologies to meet waste plastic recycling at home or abroad.

This pet recycling machine could be display "L" or "U" shape according clients' workshop.

Welcome your inquiry. Commitment to environmental protection starts from you and me!!!

We can design different pet bottle plastic recycling machine for you according to your request:

a: There are different capacity can be supplied:500kg/h,1000kg/h.....2000kg/h.

b: You can choose different devices according to your material.

c: According to your country condition, you can choose full automatic line or semi-automatic line.

d: You can purchase separate device based on your own conditions.

e: We providing turn-key project for you. Design-product-installment-testing.

Basically the standard process design as below:

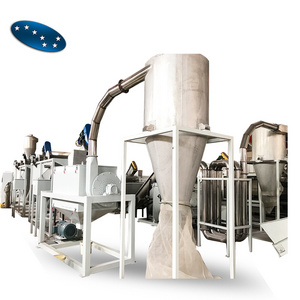

Belt Conveyor ------ Label Remover -------- Manual Selection platform (Metal Detector) ------ Belt Conveyor ----- Crusher ------- Screw Feeder ------- Hot Washer ------- Screw Feeder -------- High Speed Friction Washer -------- Floating Washing Tank ------- Dewatering ------- Dryer and Storage

Technical Parameter

|

Input capacity |

500kg/h |

1000 kg/h |

2000 kg/h |

|

Workshop(M*M*M) |

40 (L)×10(W)×6(H) |

55(L)×15(W)×6(H) |

70(L)×18(W)×6(H) |

|

Ancillary staff |

4Persons |

6Persons |

8Persons |

|

Installation power |

156KW |

307KW |

420KW |

|

Water Consumption: |

2Ton/h |

3Ton/h |

4Ton/h |

|

Final product |

Moisture: max 1% Bulk density: 0.3G/CM 3 Particle size: 1-12mm Metal content: |

Moisture: max 1% Bulk density: 0.3G/CM 3 Particle size: 1-12mm

|

Moisture: max 1% Bulk density: 0.3G/CM 3 Particle size: 1-12mm

|

Features and Application of pet bottle plastic recycling machine :

a. Equipment name: pet bottle recycling plant

b. Production capacity: 300-2000kg/h

c. Material processed: PET bottle

d. Main usage: This plant is used to remove bottle labels,crush bottle into flakes,wash by water,dry flakes,then get the clean and dry bottle flakes.

e. Superiority: Easy operation, high capacity, low energy consumption, safety, reliability, etc.

f. Production capacity: can reach 3000kg/h (if without label remover machine).

Machines Photos

Our factory

Shipment

Our Service

Pre-sale: we given client the details technician offer, sign the sales contract etc.

In-sales: we supply the details layout, installation instruction, technician support for the clients.

After sales: we arrange engineer to install the machinery and training the workers for client. We always up date the new technology to every customer.

For more details and best offer, please contact us. We are always at your service.