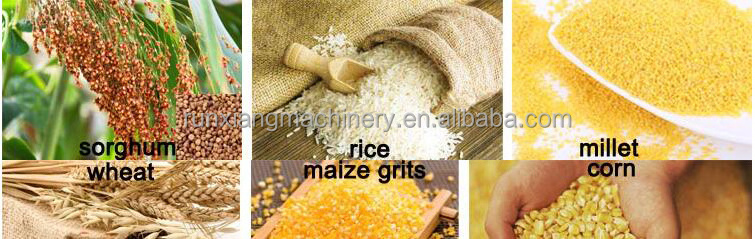

The dry fish feed machine requires several raw materials to operate effectively. The most important raw materials include fish meal, soybean meal, corn flour, rice bran, wheat bran, and various vitamins and minerals. These materials are mixed in varying proportions depending on the type of fish being fed, their stage of growth, and the nutritional needs of the fish.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Customize

-

Weight:

-

150 kg

-

Application:

-

Poultry Farm

-

Product name:

-

Animal Feed Pellet Plant

-

Name:

-

Fish Feed Pellet Extruder

-

Usage:

-

Animal Poultry Livestock Feeding

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Raw material:

-

Wheat Bran Hay Grass Straw

-

After-sales Service Provided:

-

Engineers

-

Keywords:

-

Poultry Feed Processing Equipment

-

Capacity:

-

100---3500kg/h

-

Final product:

-

Pellet Food

Quick Details

-

Max. Capacity:

-

200KG/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Runxiang

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Customize

-

Weight:

-

150 kg

-

Application:

-

Poultry Farm

-

Product name:

-

Animal Feed Pellet Plant

-

Name:

-

Fish Feed Pellet Extruder

-

Usage:

-

Animal Poultry Livestock Feeding

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Raw material:

-

Wheat Bran Hay Grass Straw

-

After-sales Service Provided:

-

Engineers

-

Keywords:

-

Poultry Feed Processing Equipment

-

Capacity:

-

100---3500kg/h

-

Final product:

-

Pellet Food

Product Description

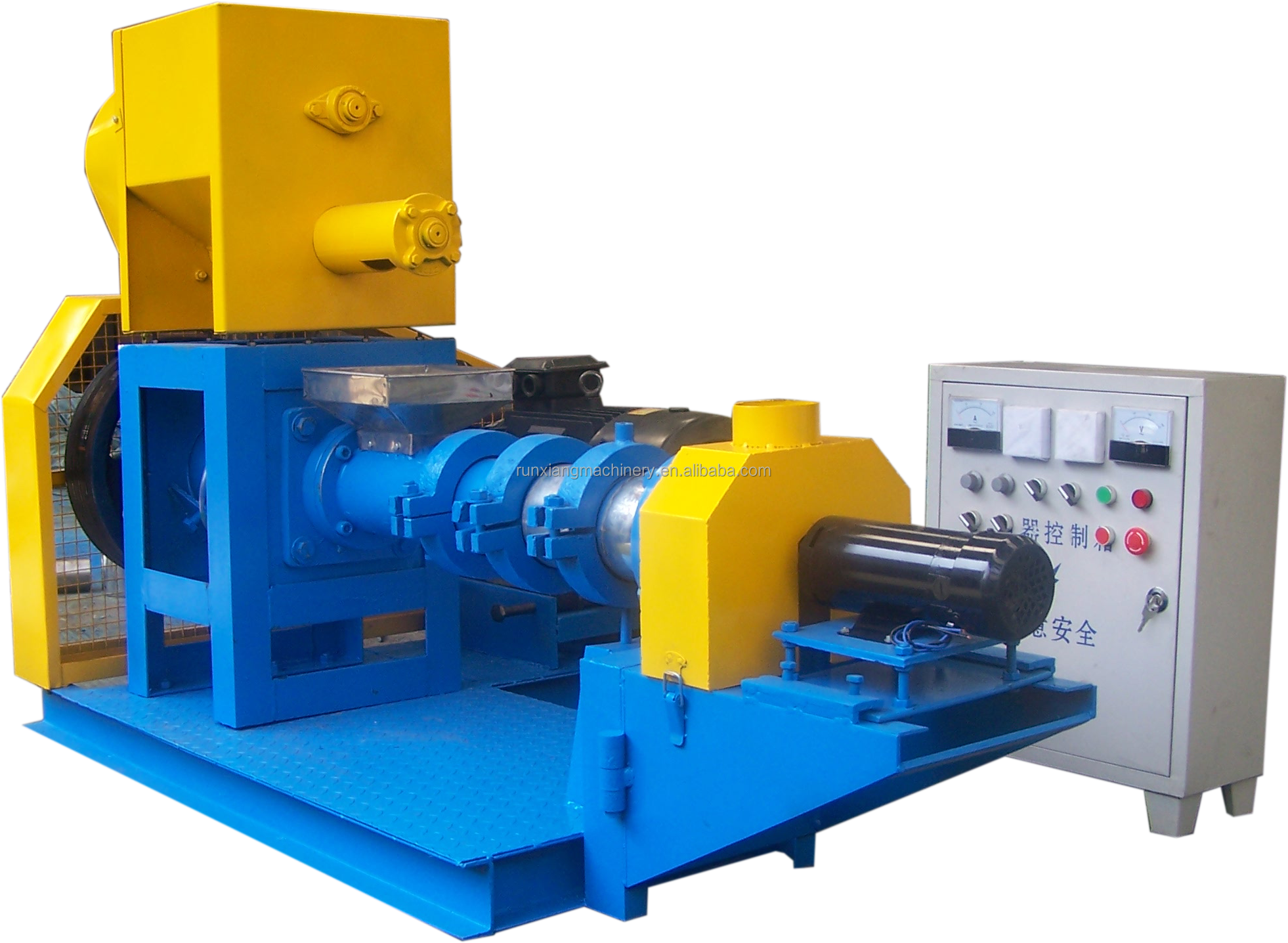

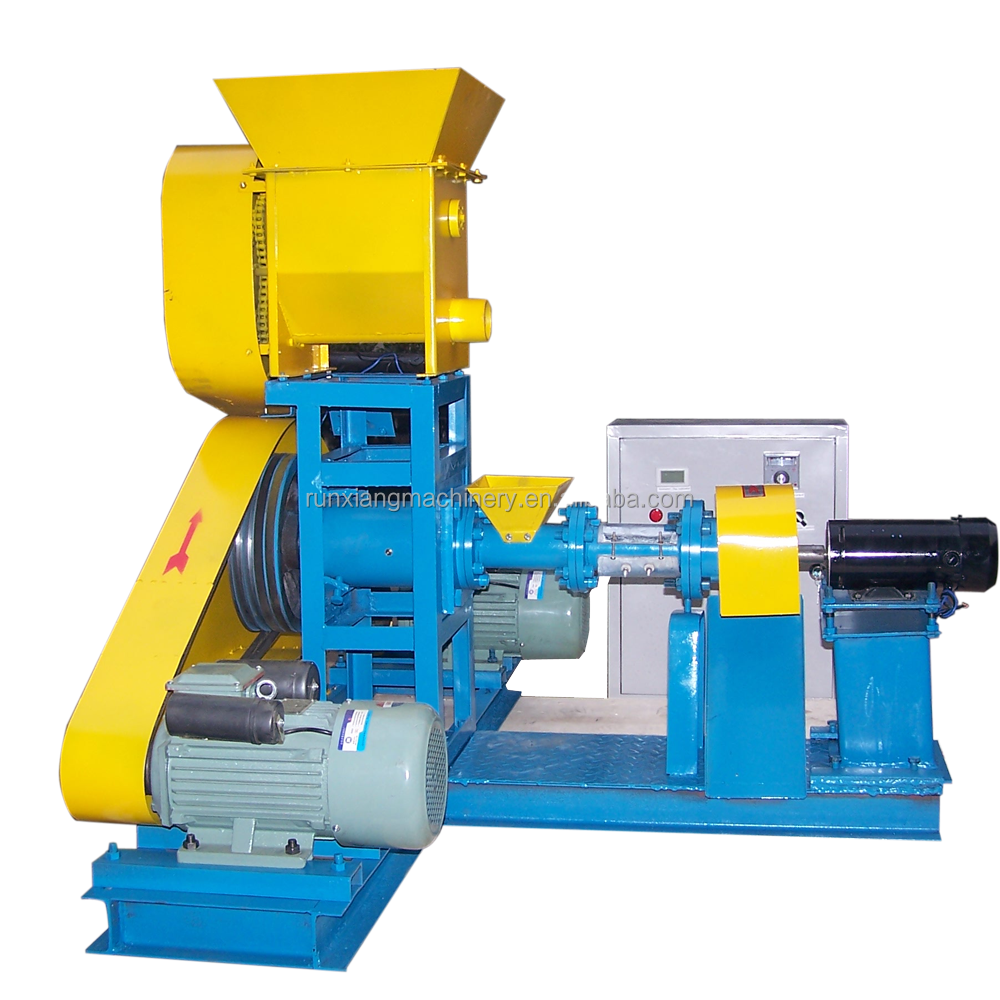

The dry fish feed machine is a type of machine that is used to make dry fish feed for fish farming. It is a vital tool in the fish farming industry as it allows fish farmers to produce their own fish feed rather than rely on commercial fish feed which can be costly. The machine is designed to process raw materials into pellets that can be easily consumed by fish.

Adventure

1.I

t provides fish farmers with a cost-effective way to produce high-quality fish feed. This can help to reduce the overall production costs of fish farming and lead to increased profits.

2.

It allows fish farmers to produce customized fish feed that meets the nutritional needs of their fish, which can lead to healthier fish and higher yields.

3.T

he dry fish feed machine is easy to operate and maintain, and does not require a lot of space, making it ideal for small-scale fish farmers.

Raw material

Different material

Final product

A dry fish feed machine can produce various types of products, including pellets, flakes, and granules of different sizes and shapes. These products can be formulated with different ingredients and nutrients to cater to the specific nutritional needs of different fish species and growth stages. Additionally, dry fish feed machines can also produce specialized feeds, such as floating or sinking feeds, and medicated feeds that contain additives and medications to promote fish health and prevent diseases.

Application

Use of

Fish Feed Machine

The dry fish feed machine is primarily used to produce dry fish feed for fish farming. It helps fish farmers to reduce their production costs by producing high-quality fish feed at a fraction of the cost of commercial fish feed. Additionally, it allows fish farmers to customize their fish feed to meet the nutritional needs of their fish, which can lead to healthier fish and higher yields.

Working principle:

Working Principle of the Dry Fish Feed Machine

The dry fish feed machine works based on a simple principle. The raw materials are mixed together in a mixing chamber and then passed through a die, where they are compressed and shaped into pellets. The pellets are then dried and cooled before being bagged for storage or sale. The machine is operated by an electric motor or diesel engine, which powers the various components of the machine.

Technical information

|

Model

|

WSJY-40

|

WSJY- 50

|

WSJY-60

|

WSJY-70

|

WSJY-80

|

WSJY-90

|

WSJY-120

|

|

Capacity --- kg/h

|

30-40

|

60-80

|

120-150

|

180-250

|

300-350

|

400-450

|

500-700

|

|

Pelleting Diameter--- mm

|

1-8

|

1—8

|

1 —10

|

1-10

|

1 —10

|

1 —10

|

1-10

|

|

Motor Power--- kw

|

5

|

7.5

|

15

|

18.5

|

22

|

37

|

55

|

|

Cutting Power--- w

|

400

|

400

|

400

|

400

|

1100

|

1500

|

2200

|

|

Screw Rod Diameter-- mm

|

40

|

50

|

60

|

70

|

80

|

90

|

120

|

|

Cooking degree

|

>95%

|

>95%

|

>95%

|

>95%

|

>95%

|

>95%

|

>95%

|

|

Size(m)

|

1.4*1.03*1.1

|

1.45*1.08*1.25

|

1.46*1.14*1.25

|

1.6*1.4*1.35

|

1.6*1.4*1.35

|

2.1*1.45*1.35

|

2.1*1.45*1.35

|

|

Weight(kg)

|

260

|

350

|

355

|

580

|

700

|

950

|

1700

|

Packaging

Package

All of our machines will be wooden package,totally

conform to the export standard.

Our Company

FAQ

Hot Searches