- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Silicone Core Duct Machine

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

20mx2.5mx2.2m

-

Power (kW):

-

150

-

Weight:

-

6000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Hopper volume:

-

10L

-

Center height:

-

1000mm

-

Gearbox type:

-

Hard surface, Material 20CrMnTi Type:125

-

Screw diameter:

-

50mm

-

Speed adjusting method:

-

Motor speed adjustable

-

Soakage method:

-

Oiliness bevel wheel lubricated

-

Automatic Grade:

-

Automatic

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

15 rpm

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Silicone Core Duct Machine

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

20mx2.5mx2.2m

-

Power (kW):

-

150

-

Weight:

-

6000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Hopper volume:

-

10L

-

Center height:

-

1000mm

-

Gearbox type:

-

Hard surface, Material 20CrMnTi Type:125

-

Screw diameter:

-

50mm

-

Speed adjusting method:

-

Motor speed adjustable

-

Soakage method:

-

Oiliness bevel wheel lubricated

-

Automatic Grade:

-

Automatic

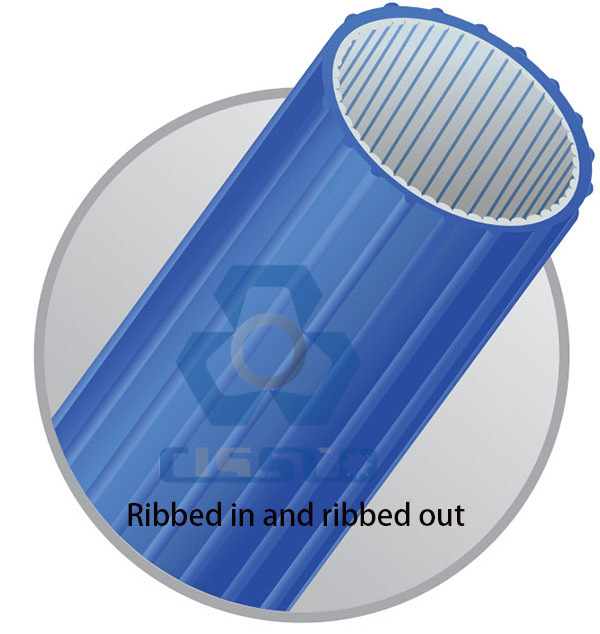

Ribbed in Smooth out HDPE Silicone Microduct Extruder

I. Specifications of the duct

- Raw material: HDPE + silicon granule;

- Color of pipe: customizable;

- Size of pipe: OD 8-16mm

- Eccentricity : <=0.10

- Internal and external surface of pipe should be smooth and single color, should be uniform wall thickness, no manufacturing defect and air bubble, shrinkage, crack, non-uniformity etc.

- For a single microduct, there are 3 typical types:

- Type 1: ribbed in and ribbed out:

- Type 2: ribbed in and smooth out:

-

Type 3: smooth in and smooth out:

- Some of the mutilduct from our machine:

II. Common information of machine line

1. In view of operation safety, machine equipped with:

- E-stop switch;

- Control system to prevent machine from damaged at abnormal condition;

- Flash lamp and voice show machine is under abnormal running condition;

- The parts which probably cause damage to operation staff are all designed with protection.

2. The following technical documents included in the content of purchasing object:

- Installation layout diagram of machines;

- Circuit diagram of machines;

- Operation manual of machines;

- Certificate of machine quality;

- Certificate of machine warranty by supplier;

- Spare parts (refer to spare parts list).

3. Name and model : SXG-75X45X25T Silicon core HDPE tube extrusion line

- Output: Max 160 ± 10%Kg/h, expected producing speed: 0–100 m/min;

- Environment: Indoor, humidity 0.85, no condensation point, temperature<=40℃;

- Power supply: 380V 50HZ, 3-phase 4wires; Install power <=160KW;

- Circulation water flow: 12-14.0m3/h;

- Compressed air: 0.6-0.7Mpa.

- Operation direction of production line is from right to left direction;

- Core height of production line is 1100mm;

- Install space: 23.0m x 3.5m x 3.5m (length x width x height);

- Color of machine: RAL 7035; Or according to client appointed color;

IV. Configuration of Silicon core HDPE tube extrusion line

| Item. | Equipment Name | QTY/set |

| 1.1 | Automatic loader | 3 |

| 1.2.1 | Hopper dryer | 2 |

| 1.2.2 | Mixer | 1 |

| 2.1 | HDPE Single screw extruder | 1 |

| 2.2 | Silicon Single screw extruder | 1 |

| 2.3 | HDPE Single screw extruder | 1 |

| 2.4 | Volumetric type co-extrusion mold | 1 |

| 3.1 | Full sealing precision vacuum sizing tank | 1 |

| 3.2 | Cooling tank | 1 |

| 4 | PROTON bidirectional high speed laser diameter gauge | 1 |

| 5 | Belt type puller | 1 |

| 6 | Double-position coiling machine | 1 |

V. Detailed technology of Silicon core HDPE microduct extrusion line

|

Co-extrusion extruder:

1. Single screw extruder for hdpe. 2. Single screw extruder for silicone. 3. Single screw extruder for mark line. |

|

|

Volumetric type co-extrusion mold:

1. Material of mold body: 40Cr. 2. Structure of mold: High pressure volumetric mold, can realize high speed, high precision production. 3. Mandrel and die: Material is High class “H13” die steel, precision grinding. |

|

|

Cooling tank:

1. Specification: Length 6000mm, width 180mm, depth 180mm, made by SUS304 material, opened structure. 2. Water circulation system: Circulation water reservoir (SUS304)—1set, circulation water reservoir built-in level control device. |

|

|

Belt type puller:

1. Belt: Multi layer wear-resistant belt, 2pcs. 2. Specification of belt: Effective contact length 800mm, width 80mm, clamping height 0-80mm. 3. Speed setting: 6.0 - 60m/min. |

|

|

Double-position coiling machine:

1. Coiling plate: Double-position coiling (winding plate specification 1200mm out-diameter). 2. Coiling motor: AC motor, with inverter. 3. Tension regulator: Automatic regulating winding speed and traversing speed according to tension state of tube. |