- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.8%

-

Voltage:

-

220/380/415V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Bievo

-

Dimension(L*W*H):

-

2600*1800*2100mm

-

Weight:

-

3500 KG

-

Suitable for:

-

Carbonated Soft Drink Line

-

Function:

-

Washing Filling Capping

-

Capacity:

-

2000-22000Bph

-

Processing Types:

-

Gas Drinks

-

Bottle type:

-

PET Plastic Bottle

-

Filling range:

-

330-1500ml

-

Applicable Cap Shape:

-

Plastic Screw Cap

-

Control:

-

PLC

-

Material:

-

Stainless Steel 304

-

Color:

-

Silver Gray

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Beer, Other

-

Filling Accuracy:

-

99.8%

-

Voltage:

-

220/380/415V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Bievo

-

Dimension(L*W*H):

-

2600*1800*2100mm

-

Weight:

-

3500 KG

-

Suitable for:

-

Carbonated Soft Drink Line

-

Function:

-

Washing Filling Capping

-

Capacity:

-

2000-22000Bph

-

Processing Types:

-

Gas Drinks

-

Bottle type:

-

PET Plastic Bottle

-

Filling range:

-

330-1500ml

-

Applicable Cap Shape:

-

Plastic Screw Cap

-

Control:

-

PLC

-

Material:

-

Stainless Steel 304

-

Color:

-

Silver Gray

Detail determines quality

We have confidence in the quality of our products because of our professional technology and experienced staff team.

We always adhere to the “Control every procedure well, make each product well”.

Products Description

DGZ series filling machine - Washing filling capping 3-in-1

This series is a unique design combining the three machines of bottle washing,filling and capping in one to decrease main power,to save space and to diminish the air pollution among the three machines. It is applicable for carbonated beverage and beer filled in plastic bottles and capped with plastic caps,with optional capacity from 2000 BPH to 22000 BPH. It uses frequency changer to control the main machine motor. And it has an output number indicating function which is easy to control the adjustment of the output.

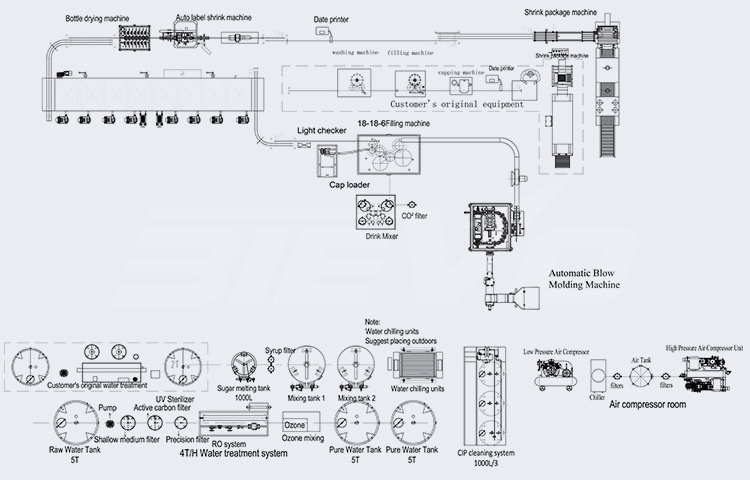

Related Equipment

:

1.Water treatment system: to the measures taken to make the water quality meet certain use standards.

2.Cap loader: the frame is welded from high quality carbon steel, and the surface is treated with rust prevention and spraying, and the surface is covered with stainless steel plate.

3.Bottle blowing machine: the bottle blowing machine is for making plastic bottles. It is suit for mineral water, carbonated drink, beer, wine and juice packaging.

4.Filling machine: this machine is mainly used in the beer filling operations. The three functions of bottle washing, filling and capping are composed in one body of the machine.

5.Sleeve labeling machine: it is widely suitable for different material of container and label. The label cost is comparatively lower.

6.Pasteurized tunnel sterilizer: is specially for dairy, juice, beverage, beer, food, medicine and other filling or packaging pasteurization equipment, is the material through sterilization, cooling to achieve the purpose of extending the shelf life of the ideal equipment, especially the automatic production line necessary for secondary sterilization equipment.

7.Bottle drying machine: blow dry the outside of the bottle.

8.Shrink package machine: with full automatic functions of bottle transfer and arrange, film wrapping, sealing and cutting, shrinkage, cooling and other qualities.

9.Date printer: printing the date on the bottled water.

10.Drink mixer: This machine could proportionally mix syrup, additive, drinking water and aerate CO

2

into beer finished beverage before bottling. It also could thin beer or aerate beer or produce sparking wine before bottling.

11.Sugar melting tank:suitable for milk, syrup, fruit juice, food and other substances melt disinfection, heating cooking and heat preservation.

Product Paramenters

|

Model

|

DGZ

12-12-6

|

DGZ

18-18-6

|

DGZ

24-24-8

|

DGZ

32-32-8

|

DGZ

40-40-10

|

DGZ

50-50-12

|

DGZ

60-60-15

|

||||||

|

Production Capacity(bph)

|

2000-3000

|

3000-5000

|

6000-8000

|

8000-11000

|

12000-15000

|

15000-18000

|

18000-22000

|

||||||

|

Filling Pressure(Mpa)

|

≤0.4

|

|

|

|

|

|

|

||||||

|

Applicable Bottle Type

|

Bottle Diameter: Φ50-Φ100 mm Height: 150-320 mm Volume: 330-1500 ml

|

|

|

|

|

|

|

||||||

|

Applicable Cap Shape

|

Plastic Screw Cap

|

|

|

|

|

|

|

||||||

|

Gas Source Pressure(Amp)

|

0.6

|

0.6

|

0.6

|

0.6

|

0.6

|

0.6

|

0.6

|

||||||

|

Gas Consumption

(m3/min)

|

0.4

|

0.4

|

0.6

|

0.6

|

0.6

|

0.8

|

0.8

|

||||||

|

Total Power(kw)

|

4.6

|

5.4

|

6.4

|

8.5

|

11

|

12

|

15

|

||||||

|

Weight(kg)

|

2600

|

3500

|

5200

|

6500

|

8000

|

10000

|

12800

|

||||||

|

Dimension

(L*W*H)(mm)

|

2450*1650*2100

|

2600*1800*2100

|

3000*2200*2400

|

4000*2220*2400

|

4100*2700*2600

|

4500*3400*2600

|

5400*4100*2600

|

||||||

Details Images

1. Water Treatment System

Simple operation/Less maintenance/Lower power consumption.

The physical characteristics of water, such as temperature, color, transparency, odor and taste, are filtered or treated so that water can be used directly for drinking or other purposes.

According to customer's raw water analysis report and the final water standard request, We will choose the most suitable water treatment system for you!

2. PET Bottle Blowing Machine

Less bottle cost/Stable working/High bottle performance.

The bottle blowing machine is for making plastic bottles.

Bottle blowing machine is to make plastic bottles for mineral water, carbonated drink, juice and so on. It is widely used in the food and beverage package industry.

3. Carbonated Beverage Filling Machine

High filling accuracy/Famous components/Stainless steel material.

The filling machine is consisted of washing-filling-capping all together.

DGZ series filling machine adopts the suspension design. It allows the machine to fill different type of the bottles. It is normally used as carbonated beverage filling machine. However, it can also be used for fill PET bottle with

beer

by simply change the accessories.

Washing Part

<1>Rinsing water distributor ensure each working position has stable water supply, as well as cut the rinsing water consumption.

<2>Single fluid spray nozzle is used, rinse water is spraying in setting angle, and clean all parts inside of bottle with features complete rinsing and water saving. Water rinsing time is 4 seconds and dripping water is 2 seconds;

Filling Part

<1>Material of filling valve and tank are made from stainless steel 304L.

<2>High speed and precision filling technology, liquid level precision ≤±2mm;.

<3>Circling liquid tank, the liquid level is controlled by floating ball.

Capping part

<1>High speed and high precision capping technology and ensure capping inferior ≤0.2%.

<2>Capping air tightness ≥ 99.99%

<3>Adopted in constant magnetic torque capping technology. capping effect is stable and reliable.

<4>The anti-rotation blade is made by chrome material, no rust and wearable.

4. Sleeve Labeling Machine

High precision/High speed.

According to customer request and market demand ,we provide the better solution for the final product package design.

5. Bottle Packing System

Better design for final package solution, more choice for label material.

We supply the different bottle package de

s

ign. Film package ,carton box wrapper, film with tray package and so on.

6. Pasteurized Tunnel Sterilizer

Pasteurized Tunnel Sterilizer is specially for dairy, juice, beverage, beer, food, medicine and other filling or packaging pasteurization equipment, is the material through sterilization, cooling to achieve the purpose of extending the shelf life of the ideal equipment, especially the automatic production line necessary for secondary sterilization equipment.

Related products

Middle and small size mineral water / Pure water filling production Line

Like pure water, mineral water, spring water...

Why Choose Us

About us:

Set up in 2010, BIEVO leads the market in the field of liquid bottling, blow molding, labeling, packaging machinery and process technology for water, tea, juice, carbonated drinks, energy drinks, liquid, beer, edible oil, dairy and daily care products, etc.

We can customize liquid food production lines according to customers' demand. Every customer is the result of our proven experience and innovation.

Why choose us?

(1)A to Z turnkey plant provider

(2)Fully automatic or economic solution optional

(3)10+ years of global market experience

(4)Serve customers over 50 countries and regions worldwide

We can customize liquid food production lines according to customers' demand. Every customer is the result of our proven experience and innovation.

Why choose us?

(1)A to Z turnkey plant provider

(2)Fully automatic or economic solution optional

(3)10+ years of global market experience

(4)Serve customers over 50 countries and regions worldwide

BIEVO as a beverage equipment supplier, except the quality, performance and price, we focus more on the “delivery”.

BIEVO is committed to be a strategic partner of the beverage manufacturers. We’d like to help you build leading technology, excellent performance and most efficient production line with our professional equipment solutions.

Pre-Sales Service

Inquiry and consulting support.

24 hours on line answer your confusion.

Welcome to view our Factory.

Help client choose the suitable machine.

Take video as client's request.

Take client's other need into consideration.

After-Sales Service

Help client installing,commissioning and training.

We provide useful documents with machine. (machine layout,certificate,general manual book)

All spare parts are always available and free for your request in first year.

You can mail/call us at any time if have any problem. And our most experienced is always free for giving you consulting service.

Certifications

Exhibition

FAQ

Q1: Do you provide customized service?

A1: We can design the machines according your requirements(material ,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

Q2: What's your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: How long time for installation?

A3: According your machines order,we will send one or two engineers to your plant,it will take about 10 days to 25 days.

Q4: Do you have technicians for installation?

A4: We are responsible for the installation in your country, you can also arrange your staffs to our factory to learn how to operate the complete line.

Q5: What's the payment you prefer?

A5: Our standard payment terms are T/T with 30% deposits and balanced before shipment.

Q6: Where is your factory? How can i visit there?

A6: Our factory is located in Zhangjiagang City,Jiangsu Province,China.

It’s very near to Shanghai. If you fly to Shanghai,we will pick you up to visit our factory.

Hot Searches