- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Foreth

-

Model Number:

-

Corrugate Fiberglass Sheets

-

Surface Treatment:

-

Gel Coat

-

Material:

-

FRP

-

Thickness:

-

1.0-3.0mm

-

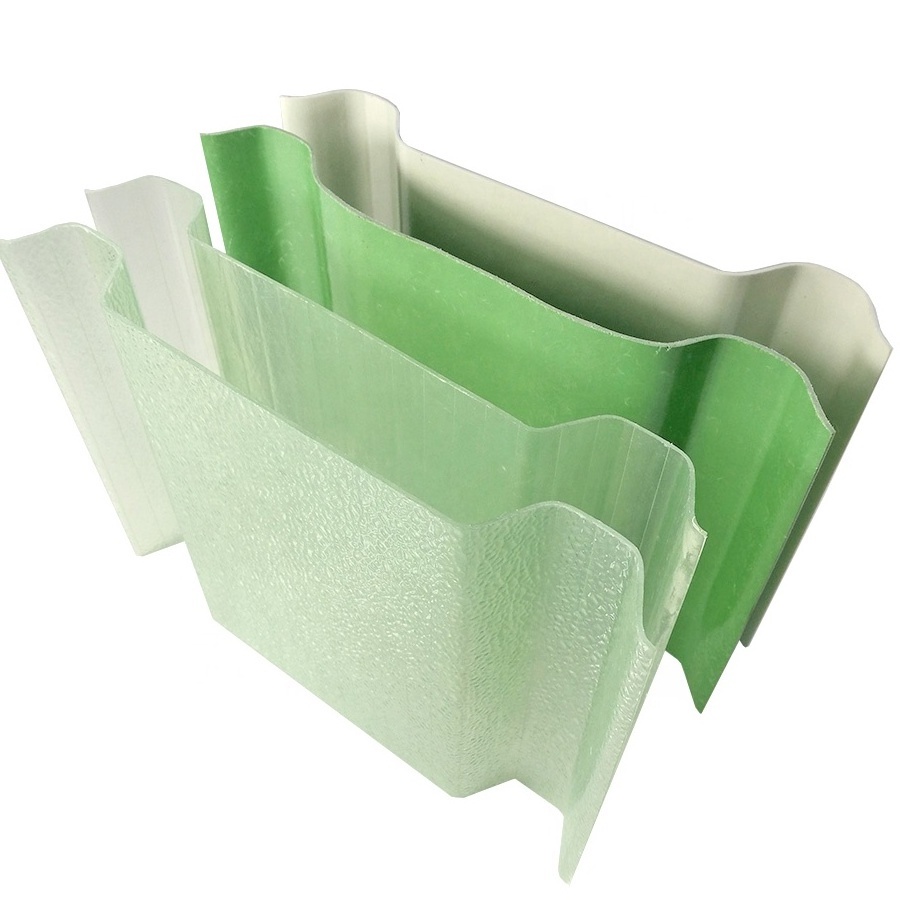

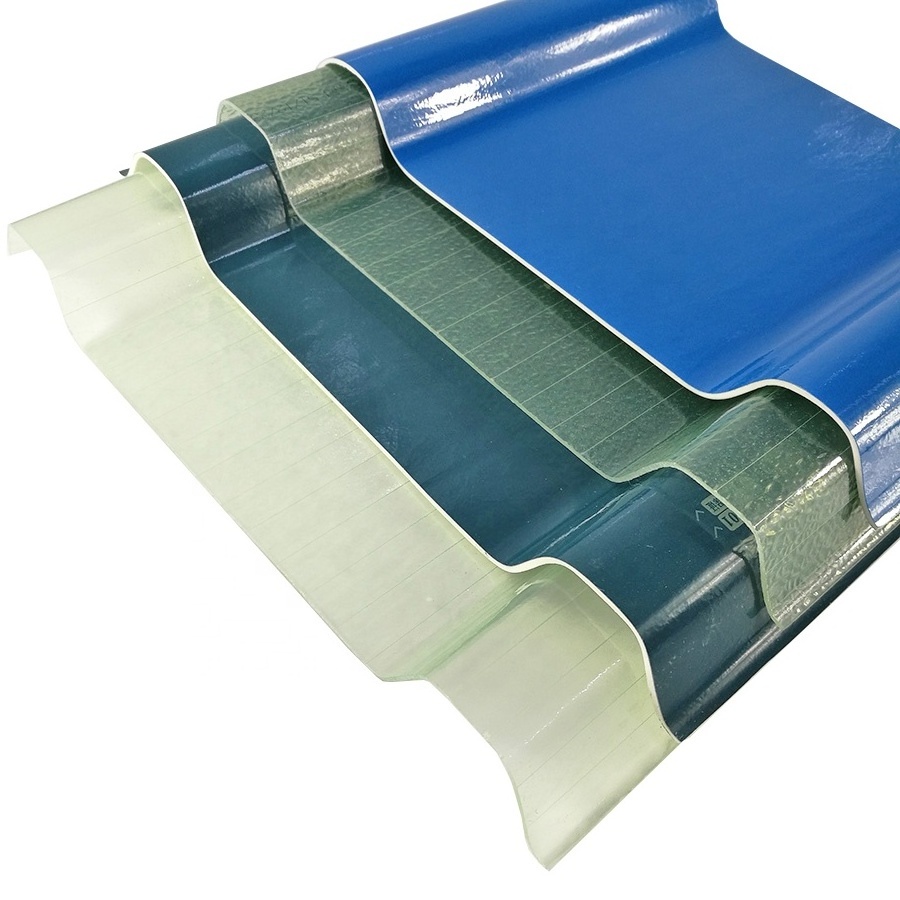

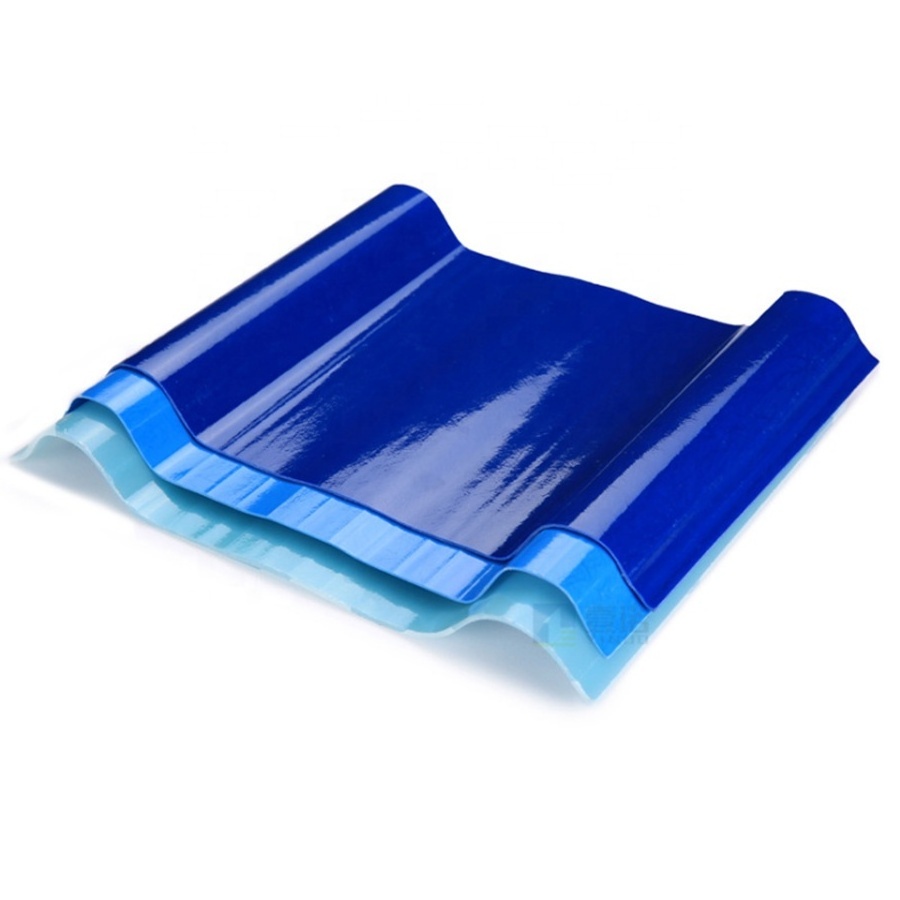

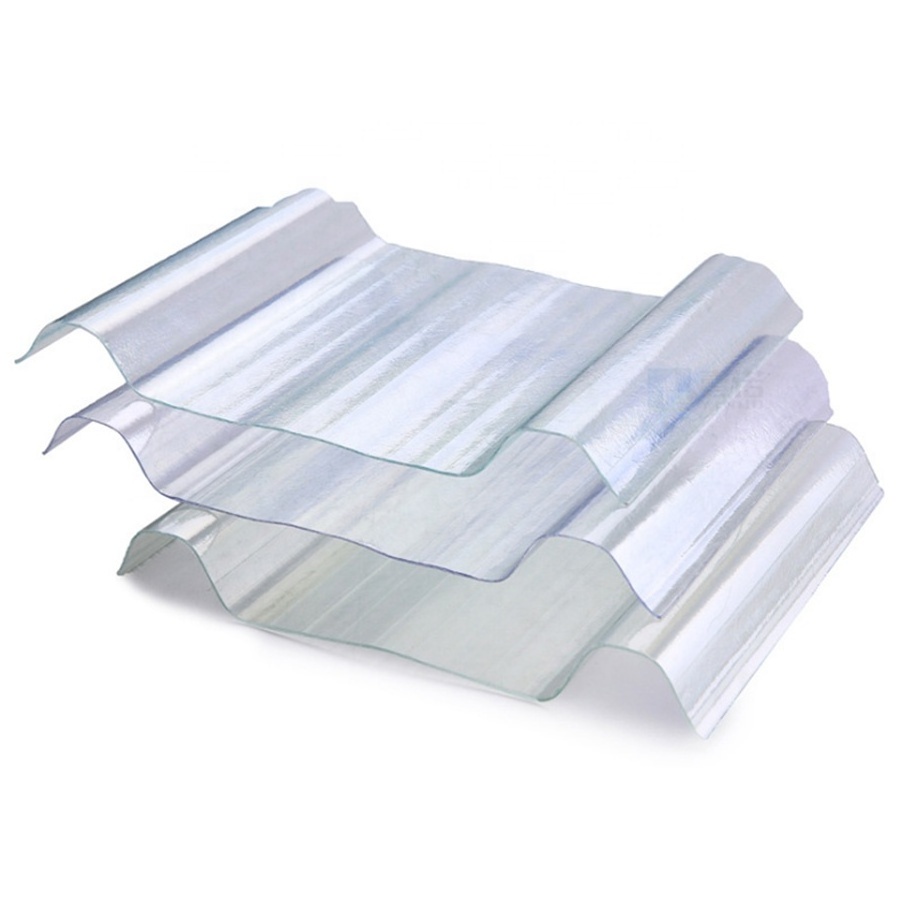

Color:

-

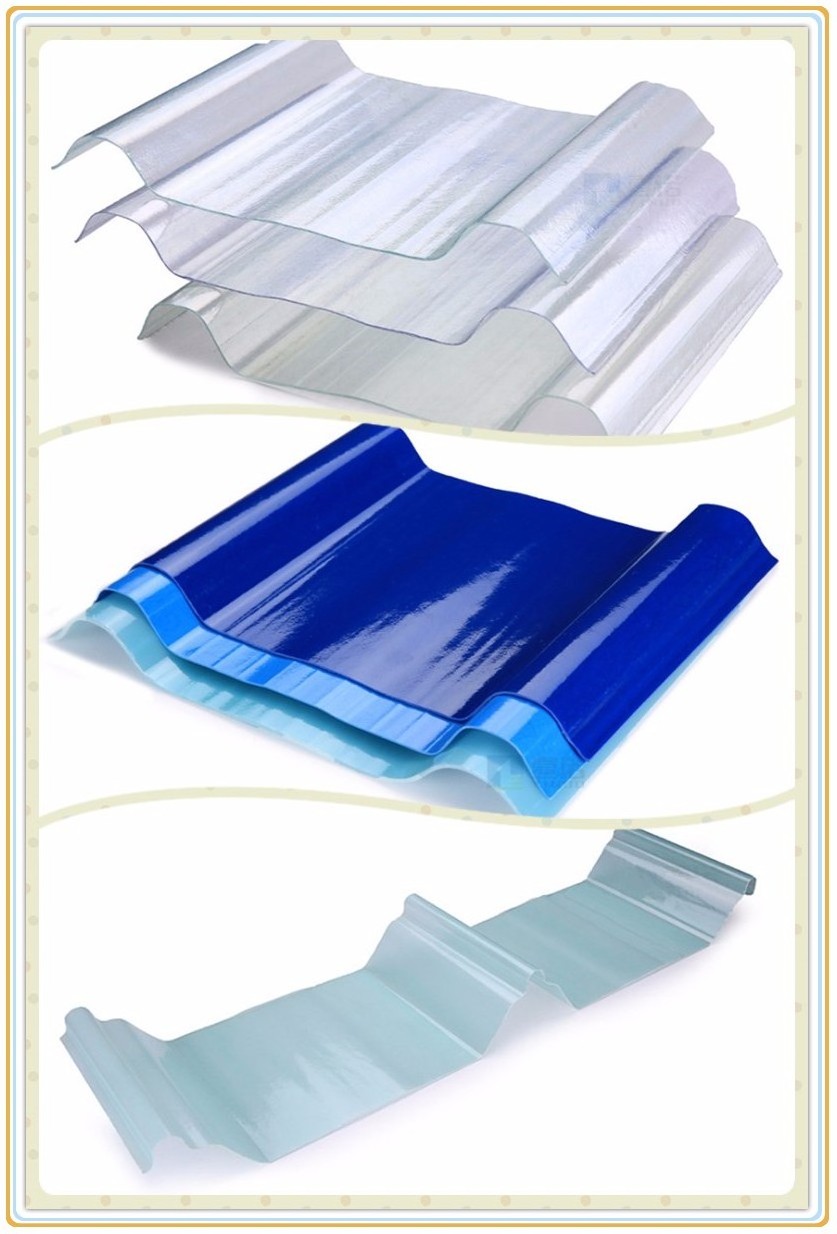

Clear, Blue, Milk white, Green, Red

-

Shape:

-

Customized

-

Density:

-

1.5g/cm3

-

Tensile strength:

-

124MPa

-

Shelf life:

-

15 years

-

Service:

-

Cutting and Free sample

-

Main market:

-

North America, Europe, southeast Asia, Brazil, the Middle East

-

Product name:

-

Corrugate Fiberglass Sheets

Quick Details

-

Application:

-

Industrial plants, warehouses, greenhouses

-

Technique:

-

Pultrusion

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Foreth

-

Model Number:

-

Corrugate Fiberglass Sheets

-

Surface Treatment:

-

Gel Coat

-

Material:

-

FRP

-

Thickness:

-

1.0-3.0mm

-

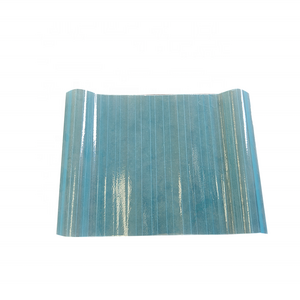

Color:

-

Clear, Blue, Milk white, Green, Red

-

Shape:

-

Customized

-

Density:

-

1.5g/cm3

-

Tensile strength:

-

124MPa

-

Shelf life:

-

15 years

-

Service:

-

Cutting and Free sample

-

Main market:

-

North America, Europe, southeast Asia, Brazil, the Middle East

-

Product name:

-

Corrugate Fiberglass Sheets

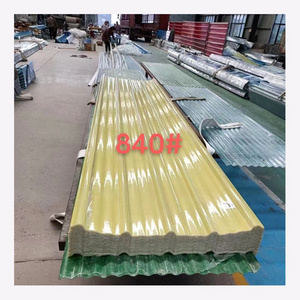

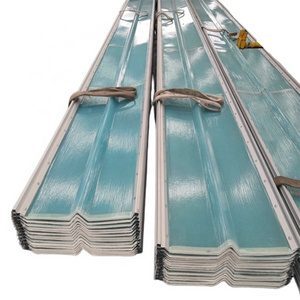

Waterproof Smooth GRP Corrugate Fiberglass Roof Lighting Sheets Factory

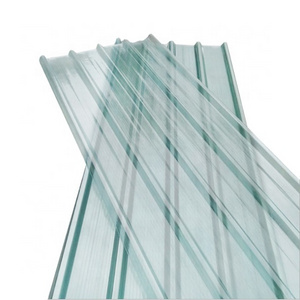

FRP Roofing Sheet Description

FRP Roofing Sheet

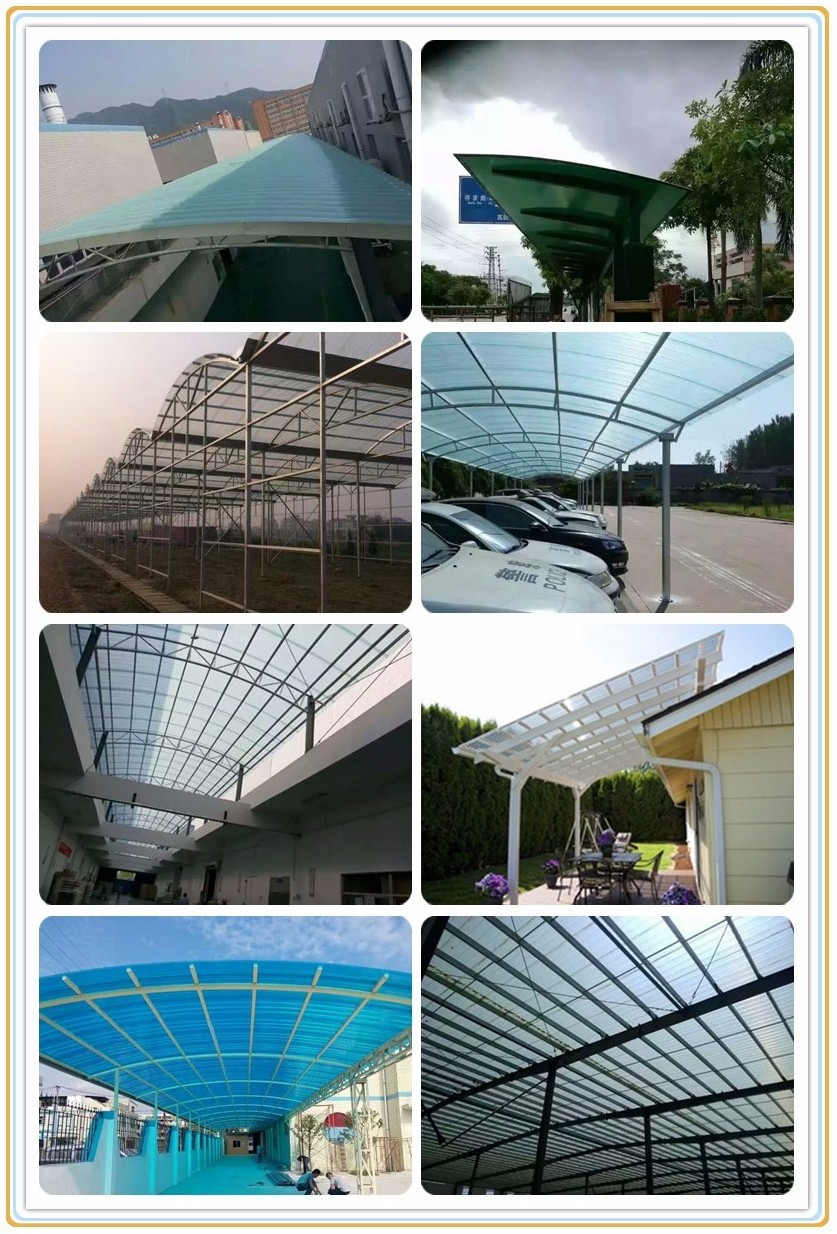

are widely used in the field of industrial plants, warehouses, greenhouses, stations, docks, airports, sports buildings, commercial buildings, steel structures and other lighting areas. FRP is glass fiber and one or several thermosetting or thermoplastic resin composite material, such as phenolic resin, epoxy resin, polyester resin, polyimide resin. Glass fiber reinforced glass fiber that is the early 20th century, the development of a new composite material, it has a light weight, high strength, corrosion, insulation, insulation, noise and many other advantages.

FRP Roofing Sheet Features

>> Weatherability: In the temperature range of -40 ℃ - 120 ℃ to maintain stable performance, no high-temperature softening, cold brittle phenomenon;

>> Low

thermal conductivity & good insulation performance;

>>

Non-toxic, non-asbestos, etc., in line with world health standards;

>>

No moss & prevent microbial growth;

>> High impact and

resistant to strong wind;

>> Safe and reliable, Not combustion-supporting in open fire;

>> Corrosion resistance, suitable for chemical workshop roof, such as fertilizer plants, electroplating factory

|

Item

|

Description

|

|

|

||

|

Material

|

FRP, ASA, PVC

|

|

|

||

|

Thickness

|

1.0mm - 3.0mm

|

|

|

||

|

Color

|

Clear, milk white, blue, green, red

|

|

|

||

|

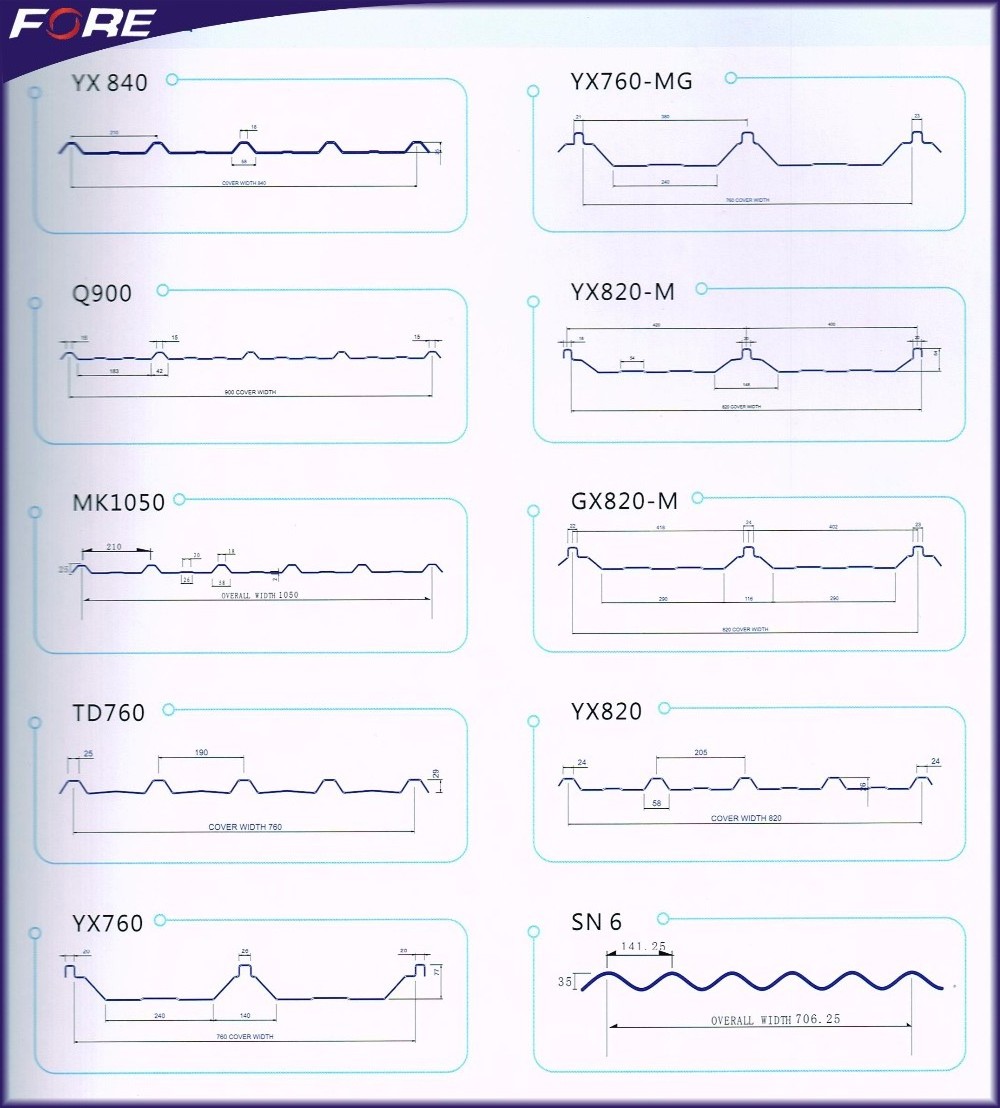

Type

|

475, 666, 760, 820, 840, 860, 900, 950, 980, 1050, can be customized

|

|

|

||

|

Shelf life

|

15 years

|

|

|

||

FRP Roofing Sheet Shape type: (can be customized)

|

Package

|

1. Loading container directly

|

|

|

|||

|

|

2. Plywood pallet

|

|

|

|||

|

|

3. Customized package

|

|

|

|||

|

Delivery

|

1. Samples & Proofing: 7-15 working days

|

|

|

|||

|

|

2. Mass Production: 7-15 working days

|

|

|

|||

|

|

3. Delivery terms: EXW, FOB, CNF, CIF, DDP all OK for us

|

|

|

|||

|

Waterproof Smooth GRP Corrugate Fiberglass Roof Lighting Sheets Factory

|

|

|

|

|||

FRP Roofing sheet applaications

>> Industrial plants, warehouses,

>> Stations, docks, airports, car parks

>> Greenhouse, aquaculture

>> Sports venues, courtyard lighting

Factory Price

1, the company professional to do FRP products

Stable Quality

2, Advanced production lines to ensure quality and stability

Fast Lead Time

3, Normally, 7-15 working days is enough

Shenzhen Hongfu Tongxin Technology Co., Ltd

is a fast-developing enterprise which is mainly specialized in FRP(fiber reinforced plastic) products, and operates in a global marketplace. Foreth team supply clients with

FRP sheets, FRP sandwich panels FRP gratings, composite manhole covers,FRP profiles, FRP roofing sheets

etc,with a wide range of applications across the construction,marine,off highway,rail,water treatment and engineering industries.

For composite FRP manhole covers(also called GRP/SMC manhole covers), we could support you with various dimensions with different bearing load, such as square manhole cover,round manhole cover,FRP gratings,etc., all meet EN-124 standard.We are also professionalized in OEM &ODM to meet your customized requirement.

Additionally, we have rich experience in exporting and supplying high quality products and excellent service.

Feel free to contact us if any query you may have and we will be happy to assist you.We hope to be your reliable supplier & stable partner by establishing long time as well as joyful business relationship with your esteemed company!

1. Lighting tile to be fixed before the pilot hole, the diameter must be greater than 50% of the fixed screw diameter, in order to avoid the thermal expansion and contraction of internal stress generated by cracking light tile.

2. Lighting tiles with aluminum fasteners fixed, waveform lighting tiles with lighting and self-tapping screw bracket bracket fixed, re-seal plastic. The location of lighting tiles generally set in the cross.

3. Lighting tile and steel plate in the vertical overlap, the minimum must be 200mm overlap, and paste the two water stop.

4. Lighting tiles and self-tapping screw connection, there must be cover. Sunlight plate hot and cold deformation is large, easy to be self-tapping nail scissors, so the sun plate in the play tapping nail should open a larger hole. In the installation of lighting panels to consider the flexibility of the lighting board.

5. Lighting tile fixed, you must use a good pan of water washer, so that between the screws and lighting board in order to facilitate waterproof and dustproof. Will be set after the pan of water into the screw, the lock with electric drill purlins, the completion of the lighting plate of the fixed work.

6. Light tiles within 12m without lap, more than 12m need to overlap, lap length of 200-400mm, lap two sealant applied, no need to take the lateral adhesive, vertical color plate overlap Need to see the plate type, the general pressure plate, generally do not consider to do income side, directly with the color plate with a self-tapping screw fixed, and the application of sealed plastic, bite board to be done to close.