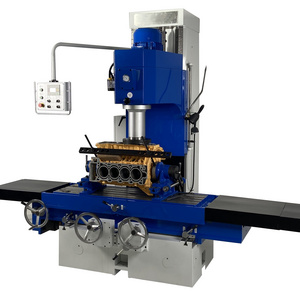

Boring Milling Machine overall layout is single vertical column, side hanging box, and fixed facing head. Worktable moves horizontally and longitudinally along the fixed bed guideway, and it could achieve 360° rotation movement. Each wall of bed, sliding base, vertical column casting has cross reinforcing rib crossed as a whole to ensure the good rigidity of the casting structure.

- Product Details

- {{item.text}}

Quick Details

-

Max worktable bearable weigh:

-

2500kg

-

Spindle speed rotation range:

-

8-1000r/min

-

Boring shaft diameter:

-

110mm

-

Worktable working area (LxW):

-

1100x960mm

-

Main motor power:

-

7.5KW

-

Boring shaft inner hole taper:

-

Morse No.6

-

Worktable horizontal travel:

-

1250 mm

-

Worktable longitudinal travel:

-

1000 mm

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Name:

-

Low Price Horizontal Engine Block Boring Milling Machine

-

Keywords:

-

Horizontal Engine Block Boring Milling Machine

-

Max worktable bearable weigh:

-

2500kg

-

Spindle speed rotation range:

-

8-1000r/min

-

Boring shaft diameter:

-

110mm

-

Worktable working area (LxW):

-

1100x960mm

-

Main motor power:

-

7.5KW

-

Boring shaft inner hole taper:

-

Morse No.6

-

Worktable horizontal travel:

-

1250 mm

-

Worktable longitudinal travel:

-

1000 mm

Low Price Horizontal Engine Block Boring Milling Machine

Machine main parameter

|

Item

|

TX611B

|

|

Max worktable bearable weight

|

2500kg

|

|

Max spindle allowable roll-torque

|

1225N·m

|

|

Max allowable roll-torque of facing head

|

1960N·m

|

|

Max spindle bearable axial feeding resisting power

|

12250N

|

|

Spindle speed rotation steps

|

22 steps

|

|

Facing head speed rotation steps

|

18 steps

|

|

Spindle speed rotation range

|

8-1000r/min

|

|

Facing head speed rotation range

|

4-200r/min

|

|

Worktable rapid rotation speed

|

1r/min

|

|

Boring shaft diameter

|

110mm

|

|

Worktable working area (LxW)

|

1100×960mm

|

|

Max distance between spindle center line and worktable surface

|

900mm

|

|

Min distance between spindle center line and worktable surface

|

0mm

|

|

Headstock vertical travel

|

900mm

|

|

Boring shaft axial travel

|

600 mm

|

|

Facing head tool rest radial direction travel

|

180 mm

|

|

Worktable longitudinal travel

|

1000 mm

|

|

Worktable horizontal travel

|

1250 mm

|

|

Spindle boring hole diameter

|

φ50-φ240 mm

|

|

Boring shaft inner hole taper

|

Morse No.6

|

|

Main motor power

|

7.5KW

|

|

Machine overall size

|

4930×2870×2750 mm

|

|

Machine net weight

|

14000kg

|

Overall Layout

Boring Spindle

Spindle adopts 3-layer spindle structure, facing head shaft, hollow spindle (boring sleeve) and spindle (boring bar), which guarantees the spindle has high rotation accuracy. Spindle is supported by three points to achieve good rigidity and precision retentivity of spindle.

Worktable

Worktable is 4×90° rotation positioning. And it adopts optical sight with high positioning precision, to ensure the high boring hole accuracy when changing to another direction.

Machine horizontal guideways adopt pulling plate-type full protection, which is beautiful, and could avoid guideway lapping damage.

Headbox

In the headstock and feeding box, each has feeding movement insurance device and rapid movement insurance device. The distribution and clamping of headstock lifting and worktable longitudinal, horizontal and rotation movement adopt rhombic block clamping device, which has safe, reliable and automatic control, and centralized operation. It is time saving and reliable.

Inspection work includs checking the factory strength, processing site, assebly site, finished production site and so on.then we talk with customers about detailed request for machines, and if necessary, we could take our freinds to our customr's site for checking, to know more about the machines.

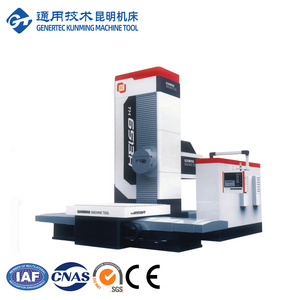

Except for Boring Milling Machine, we also have CNC lathe machine,vertical lathe machine and heavy duty lathe machine for your reference.

We are caring for our team, we are proffesional for our machines, hope could help our customers a lot when choosing machines and help sovle problems.

We group up with our customer