- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

AOMAG

-

Model Number:

-

AOMAG000412

-

MOQ:

-

1000 Pcs

-

Founded:

-

1996

-

Certification:

-

ISO9001:2008, ISO/TS16949:2009 and RoHS

-

Magnetization direction:

-

Customized , Axially, Diametrically

-

Supply Ability:

-

20000000 Piece/Pieces per Month

-

Port:

-

Fuzhou/Ningbo/Shanghai

-

Material:

-

Neodymium Magnet

Quick Details

-

Tolerance:

-

±0.05mm

-

Grade:

-

Sintered NdFeB

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

AOMAG

-

Model Number:

-

AOMAG000412

-

MOQ:

-

1000 Pcs

-

Founded:

-

1996

-

Certification:

-

ISO9001:2008, ISO/TS16949:2009 and RoHS

-

Magnetization direction:

-

Customized , Axially, Diametrically

-

Supply Ability:

-

20000000 Piece/Pieces per Month

-

Port:

-

Fuzhou/Ningbo/Shanghai

-

Material:

-

Neodymium Magnet

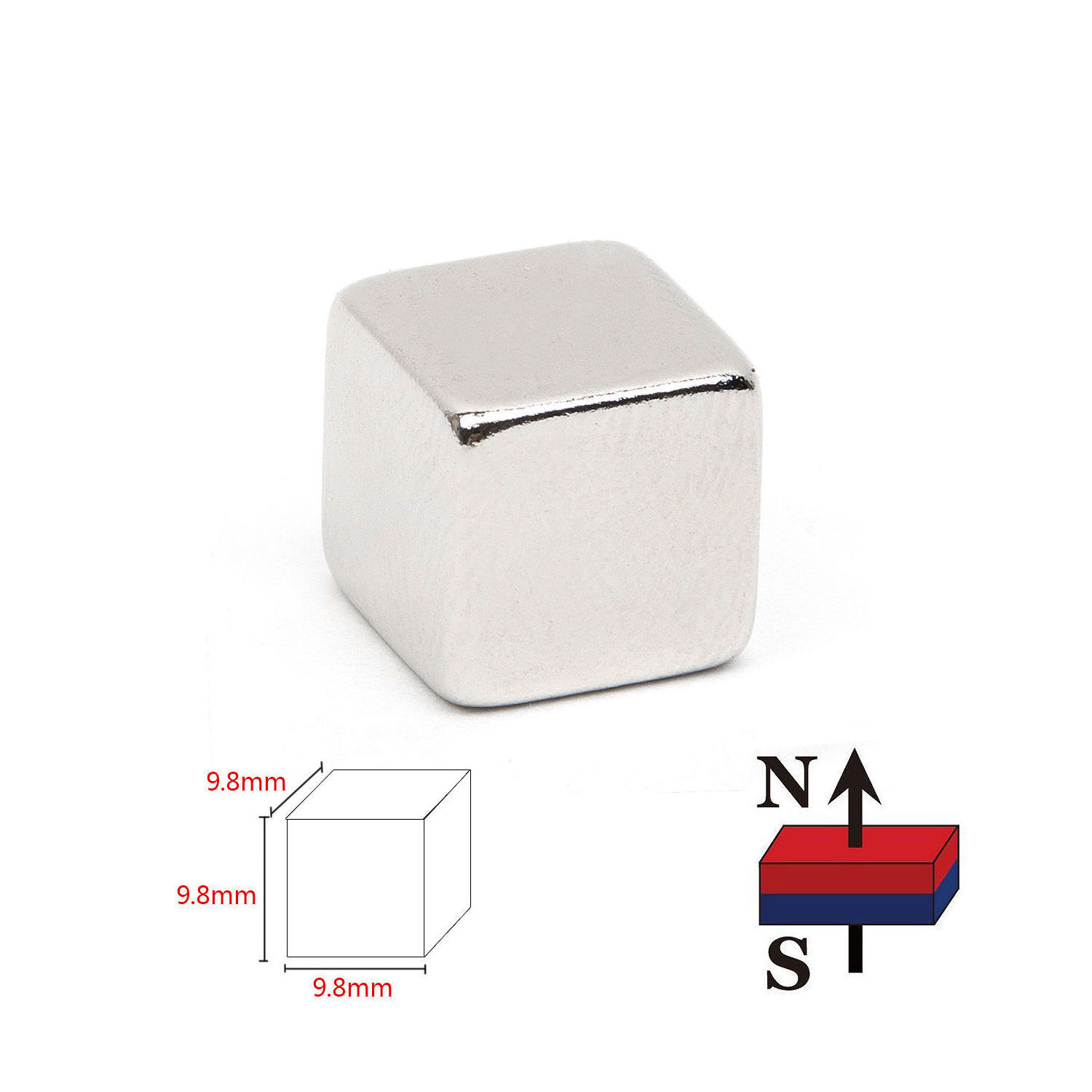

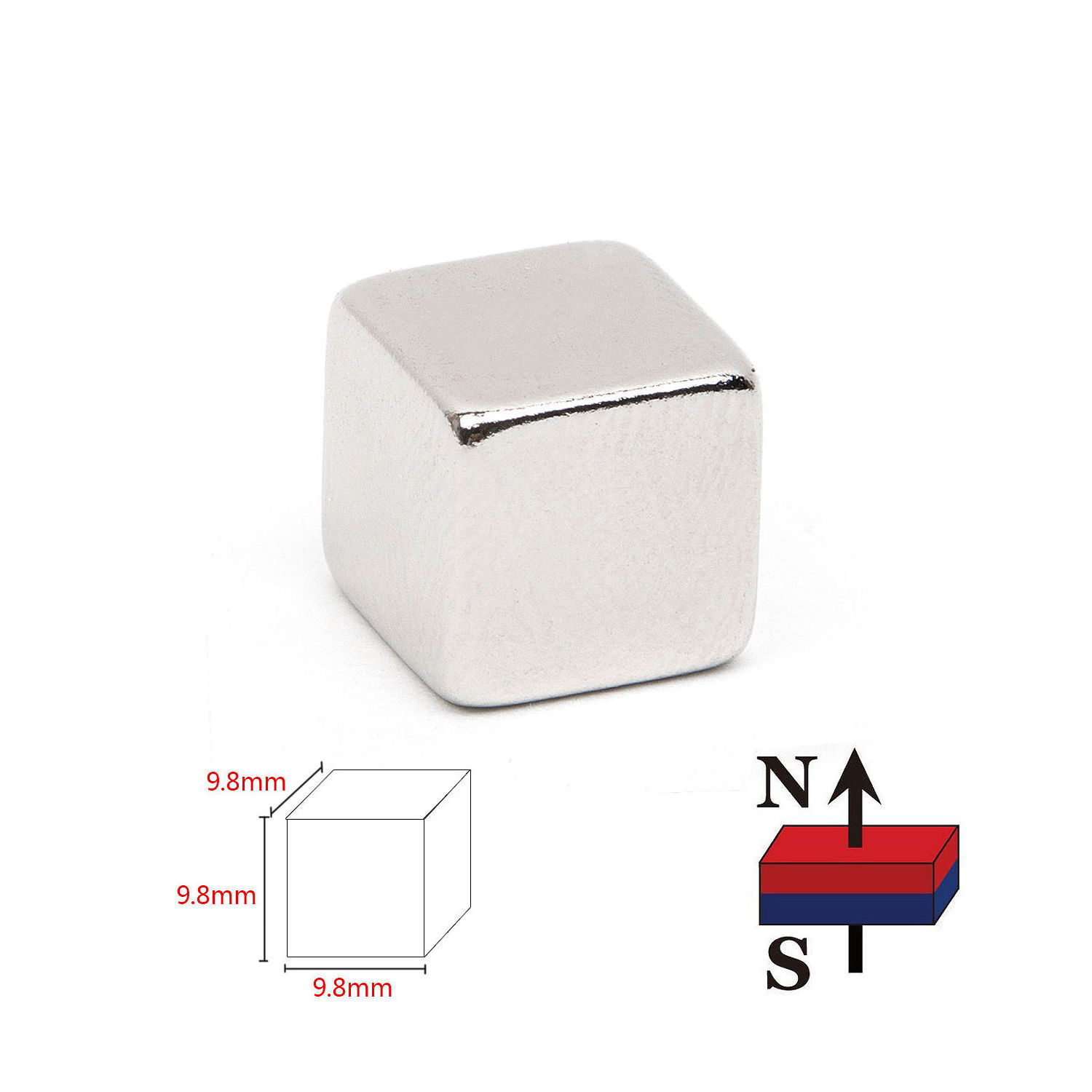

Specification

|

Products

|

Neodymium Magnet N35 N52 Magnetic Cubes

|

|

Brand

|

AOMAG

|

|

Place of Origin

|

China

|

|

Founded

|

1996

|

|

Business Type

|

Manufacturer

(Any shape and size of Neodymium can be customized)

|

|

Main Products

|

Customized NdFeB Magnets, Radial ring magnets, High Performance magnets, Sintered Neodymium magnets, Magnets

|

|

Delivery Time

|

15-30 days

|

|

Shape

|

Disc, Block, Ring, Arc and so on, Customized, All sizes

|

|

Tolerance

|

±0.05mm

|

|

Processing Service

|

Bending, Welding, Decoiling, Cutting, Punching, Moulding

|

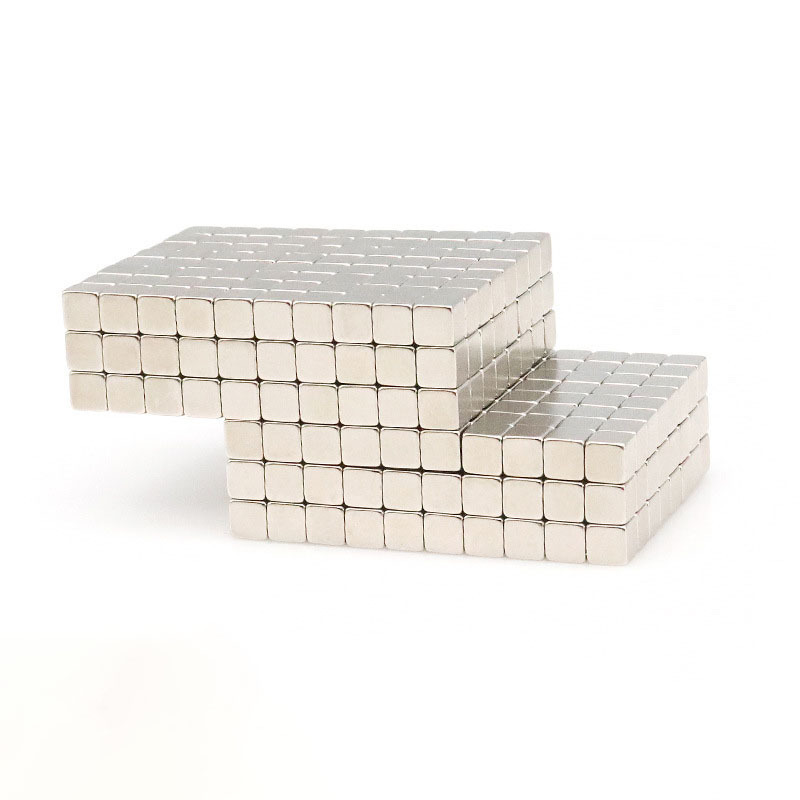

Products Description

Strong

Cube

Magent

Sintered NdFeb is the strongest magnetic permanent magnet material in the world today. Ndfeb permanent magnet is widely used for motor, instrument, electronic industry, car

washing industry, petrochemical industry, magnetic resonance, magnetic levitation, electroacoustic equipment, magnetic therapy

equipment and daily hardware tools

We accept customized services:

1) Shape and Dimension Requirements

2) Material and coating requirements

3) Processing according to design drawings

4)Requirements for Magnetization Direction

5) Magnet Grade Requirements

6) Surface treatment requirements (plating requirements)

3) Processing according to design drawings

4)Requirements for Magnetization Direction

5) Magnet Grade Requirements

6) Surface treatment requirements (plating requirements)

Customized Service

Hot Searches