- Product Details

- {{item.text}}

Quick Details

-

Year:

-

2024

-

Weight (KG):

-

500

-

Products name::

-

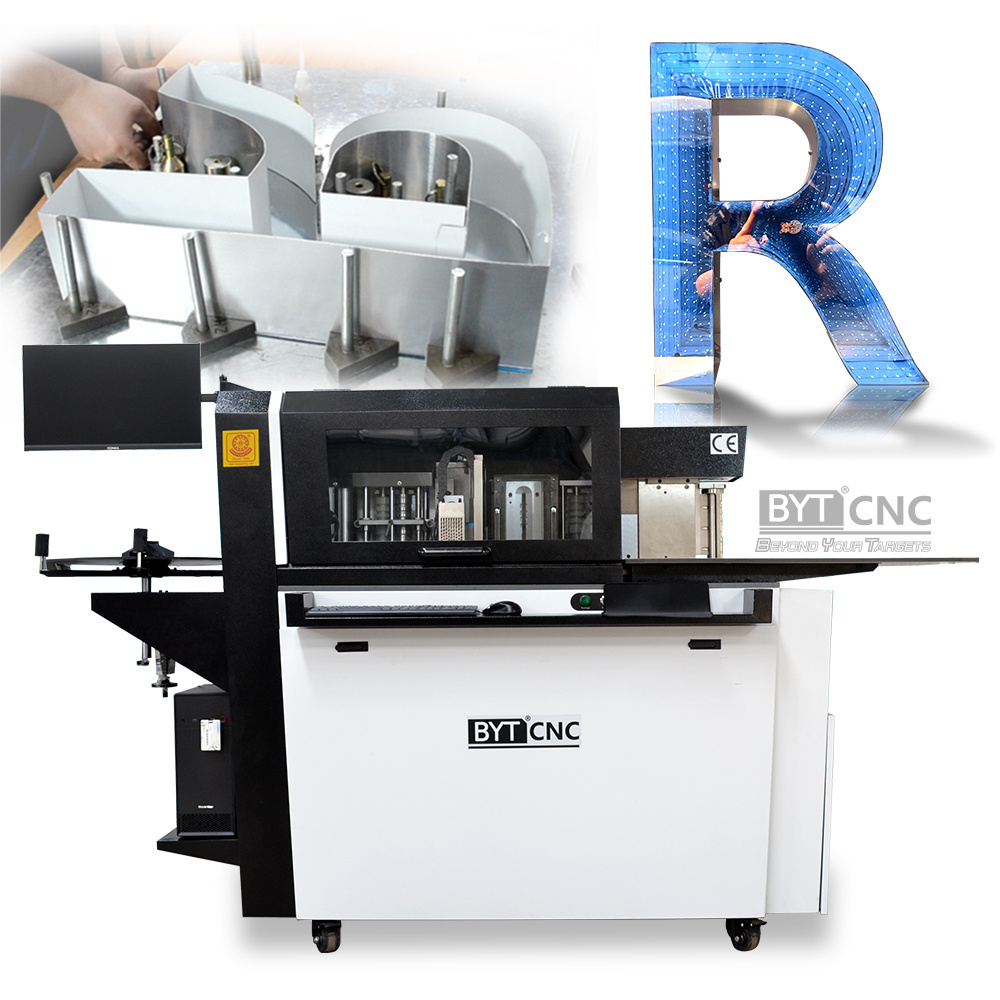

Multifunctional Channel Letter Bending Machine

-

Operation principle:

-

High precision automatic feeding,trimming,notching and bend

-

Available material::

-

Aluminum and Stainless steel

-

Material thickness::

-

0.3-1.5mm

-

Material width::

-

max 160mm letters height

-

Precision::

-

0.1mm/100Meter

-

Document format::

-

AI/DXF/PLT

-

Working Voltage::

-

220V 50HZ 1PH or Customized

-

Function:

-

Auto Feeding+bending+slotting+notching

-

After-sales Service Provided:

-

English engineer Video Technical Support

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BaoYuanTong

-

Marketing Type:

-

Multifunctional Channel Letter Bending Machine

-

Year:

-

2024

-

Weight (KG):

-

500

-

Products name::

-

Multifunctional Channel Letter Bending Machine

-

Operation principle:

-

High precision automatic feeding,trimming,notching and bend

-

Available material::

-

Aluminum and Stainless steel

-

Material thickness::

-

0.3-1.5mm

-

Material width::

-

max 160mm letters height

-

Precision::

-

0.1mm/100Meter

-

Document format::

-

AI/DXF/PLT

-

Working Voltage::

-

220V 50HZ 1PH or Customized

-

Function:

-

Auto Feeding+bending+slotting+notching

-

After-sales Service Provided:

-

English engineer Video Technical Support

1. Quality Guarantee

3.Machining parts 1

5.Easy operation ADT Control system with Length closed-loop control system

6. voltage digital display device

Feeding

Aluminum notching

Stainless steel Notching

Bending

|

Channel letter bending machine parameter |

|

|

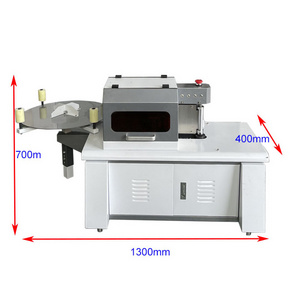

Model |

BWZ-C1 |

|

Working Principle |

High precision automatic feeding,trimming,notching and bending |

|

Processing Materials |

Flat Stainless steel ,Aluminum profile ,Iron &Copper plat and Floding Aluminum profile |

|

Material Width |

10-160mm |

|

Material Thickness |

Aluminum profile 0.3-1.5mm Stainless steel 0.3-1.2mm |

|

File format |

AI/DXF |

|

Mini pat radius |

R≥3.5MM |

|

Mini extrusion Radius |

R≥7 MM |

|

Peak Power |

2000W |

|

Length Accuracy |

0.1mm/meter |

|

Feeding Torque |

>45Nm |

|

Planer Slotted Torque Peak |

>30Nm |

|

Arc Bending Torque Peak |

>100Nm |

|

Working Pressure |

0.3-0.6mpa |

|

Voltage |

220V 50HZ 1P |

|

Overall Dimensions |

2680*880*1590mm |

|

N.Weight |

500kg |

Sales Service

4.Regular return visits to customers for technical guidance, and get high praise from customers.