- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

1J22Q

-

Shape:

-

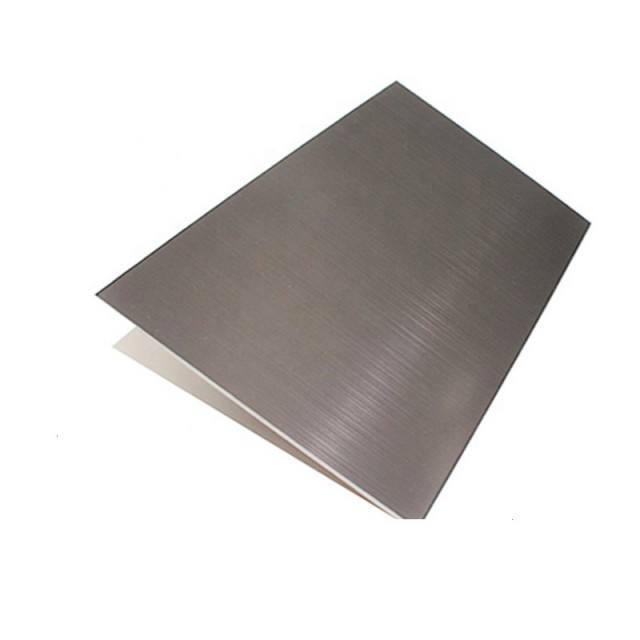

Alloy Bar/Strip/Plate

-

Material:

-

Iron Cobalt Vanadium Metal Alloy

-

Chemical Composition:

-

C,S,P,Mn,Si,etc

-

Product name:

-

1J22Q Series Fe Co V Magnetic Alloy Bar

-

Product status:

-

strip

-

Product dimensions:

-

mm 0.20-0.35

-

Heat treatment temperature:

-

770℃

Quick Details

-

Application:

-

Evaporation materials

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

xjtgy

-

Model Number:

-

1J22Q

-

Shape:

-

Alloy Bar/Strip/Plate

-

Material:

-

Iron Cobalt Vanadium Metal Alloy

-

Chemical Composition:

-

C,S,P,Mn,Si,etc

-

Product name:

-

1J22Q Series Fe Co V Magnetic Alloy Bar

-

Product status:

-

strip

-

Product dimensions:

-

mm 0.20-0.35

-

Heat treatment temperature:

-

770℃

Products Description

1J22 is an iron-cobalt-vanadium soft magnetic alloy which exhibits high magnetic saturation (24 kilogauss), high D.C. maximum permeability, low D.C. coercive force, and low A.C. core loss. This alloy is produced in strip form only and contains a small niobium addition for grain refinement during mill processing and final heat treatment of strip. 1J21 alloy is used primarily for rotor and stator laminations stamped from cold rolled strip and final annealed in a protective atmosphere or vacuum environment at a temperature which will provide an optimum combination of mechanical and magnetic properties to withstand the high stresses encountered in service. Xinjingte Technology provides 1J21 strip, as well as end to end stator and rotor stack production.

|

1J22Q (FeCoV) Typical magnetic properties

|

|

|

|

|

|

|

||||||

|

High mechanical strength/high saturation magnetic induction

|

|

|

|

|

|

|

||||||

|

Product status

|

|

|

Strip

|

|

|

|

||||||

|

Product dimensions

|

|

mm

|

0.20-0.35

|

|

|

|

||||||

|

Heat treatment temperature

|

|

℃

|

770

|

|

|

|

||||||

|

Magnetic field strength.

|

|

A/m

|

|

Magnetic induction

|

|

T

|

||||||

|

|

|

400

|

|

|

|

2.1

|

||||||

|

|

|

800

|

|

|

|

2.13

|

||||||

|

|

|

1600

|

|

|

|

2.23

|

||||||

|

|

|

2400

|

|

|

|

2.26

|

||||||

|

|

|

4000

|

|

|

|

2.3

|

||||||

|

|

|

8000

|

|

|

|

2.33

|

||||||

|

Coercive force.

|

|

A/m

|

|

|

|

94

|

||||||

|

1J22Q (FeCoV) Typical mechanical properties

|

|

|

|

|

|

|

||||||

|

0.2% yield strength

|

|

Tensile strength

|

|

|

Elongation after breaking

|

|

||||||

|

Ksi 55

|

Mpa 380

|

Ksi 165

|

Mpa 1140

|

|

16.52%

|

|

||||||

|

Heat treatment temperature 770 ℃

|

|

|

|

|

|

|

||||||

|

Chemical composition (by weight)

|

|

|

|

|

|

|

||||||

|

Carbon, ≤

|

|

|

|

0.025

|

|

|

||||||

|

Manganese, ≤

|

|

|

|

0.1

|

|

|

||||||

|

Silicon, ≤

|

|

|

|

0.1

|

|

|

||||||

|

Phosphorus, ≤

|

|

|

|

0.01

|

|

|

||||||

|

Sulfur, ≤

|

|

|

|

0.005

|

|

|

||||||

|

Chromium, ≤

|

|

|

|

0.15

|

|

|

||||||

|

Nickel, ≤

|

|

|

|

0.3

|

|

|

||||||

|

cobalt

|

|

|

|

49.00 to 51.00

|

|

|

||||||

|

vanadium

|

|

|

|

1.75 to 2.10

|

|

|

||||||

|

niobium

|

|

|

|

/

|

|

|

||||||

|

iron

|

|

|

|

Margin

|

|

|

||||||

Recommend Products

Practical Application

Hot Searches