- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FANTAI

-

Voltage:

-

380v/50hz

-

Dimension(L*W*H):

-

6.5m *1.5m *1.6m

-

Weight:

-

3000 kg

-

Input Width:

-

1000mm

-

Effective width:

-

840/900mm

-

Material Thickness:

-

0.3-0.8mm

-

Forming speed:

-

0-15m/min

-

Roller Stations:

-

12row

-

Frame:

-

300H steel weld

-

Middle plate:

-

14mm

-

Spacer:

-

seamless steel tube processing

-

Material of Roller:

-

45# steel forged

-

Material of Shaft:

-

70mm, 45#steel forged

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

0-15m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FANTAI

-

Voltage:

-

380v/50hz

-

Dimension(L*W*H):

-

6.5m *1.5m *1.6m

-

Weight:

-

3000 kg

-

Input Width:

-

1000mm

-

Effective width:

-

840/900mm

-

Material Thickness:

-

0.3-0.8mm

-

Forming speed:

-

0-15m/min

-

Roller Stations:

-

12row

-

Frame:

-

300H steel weld

-

Middle plate:

-

14mm

-

Spacer:

-

seamless steel tube processing

-

Material of Roller:

-

45# steel forged

-

Material of Shaft:

-

70mm, 45#steel forged

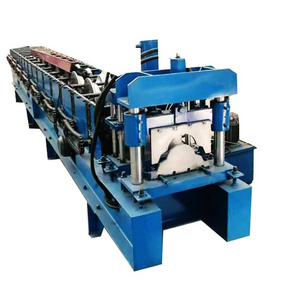

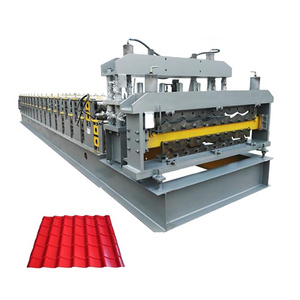

Products Description

Glazed tile roll forming machine metal roofing tile making machine for building material machinery is used for making the color glazed tiles in batch.This machine adopted PLC control cabinet achieved full automatic easy operation produce.

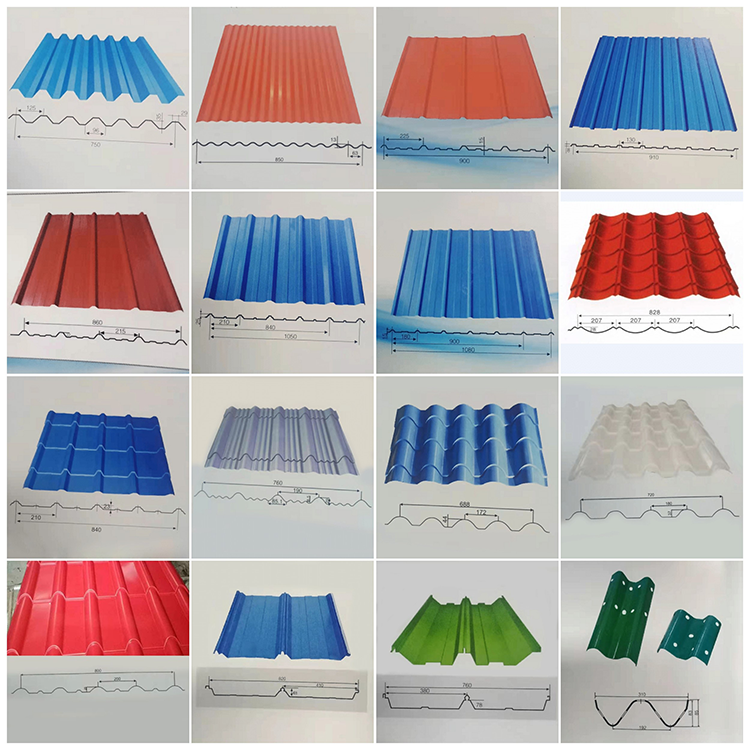

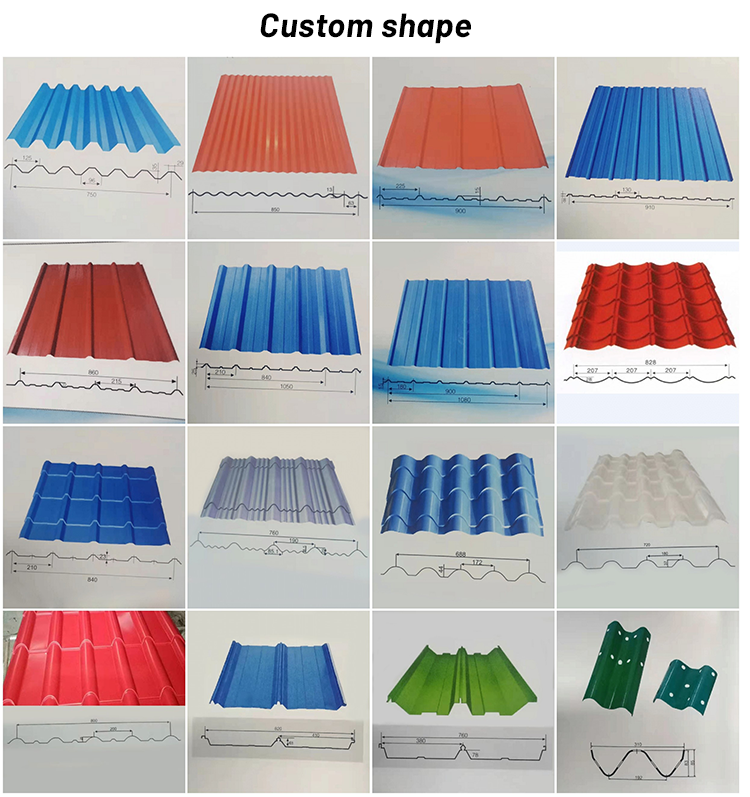

Hot sale machine roof tile drawing profile for your reference

As the machine customized,the finished products shape and machine speed specifications we can design for you as your need.

Main feature

1. This roll forming machine can roll form metal roof panels. After being rolled by this roll forming machine, the surface is very smooth and beautiful without any scratches on the surface.

2. Roll forming process: uncoiler, roll forming, forming step effect, cut to length.

3.PLC automatic control system.

4. Simple operation: input the length and quantity on the control panel.

5. We can also customize the roll forming machine, we can design the machine according to your specification and outline drawing.

Product Flows

High speed mixer---conical twin screw extruder---co-extruder---co-extrusion die head---embossing and cooling rollers---forming machine---saw cutting machine---stacker---pneumatic pressing machine for ridge tiles moulds

High speed mixer---conical twin screw extruder---co-extruder---co-extrusion die head---embossing and cooling rollers---forming machine---saw cutting machine---stacker---pneumatic pressing machine for ridge tiles moulds

Details Images

Customer stories

The finished products of glazed steel tile making machinery for color steel roof panels are widely used in the construction of various industrial plants, villages, warehouses, supermarkets, hotels, exhibitions, family buildings, shopping malls, etc., with the advantages of beauty and classicality.

Product Display

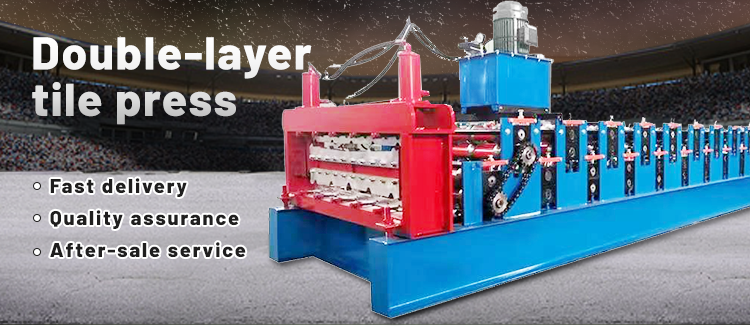

Feature:

1. More stable frame for the machine, which we can customized as your prefer one or our standrad one all is ok.

1. More stable frame for the machine, which we can customized as your prefer one or our standrad one all is ok.

2. Blade customized, if you have any more questions about the blade, or which type you prefer, you can also share with us, always welcomes for customized.

3. Plc customized. Which we also could be customized for you , such as english, spanish, or the Poland, all is ok.

3. Plc customized. Which we also could be customized for you , such as english, spanish, or the Poland, all is ok.

4. The ran out table place, which we can all customized for you. just share with you prefer one is ok.

Why Choose Us

|

Service

|

|

|

|

|

||||

|

* Quality Control

|

We have independent QC departments both in the company and factories which strictly control the quality of each process to enable our production lines to reach Chinese National Standards, even International Standards.

|

|

|

|

||||

|

* Technology R&D

|

We have R&D centers and innovative designing teams for different kinds of production lines

|

|

|

|

||||

|

* After Sale Service

|

Warranty period 1 year , after this period , we are willing to give help if customer needs accessory . The real cooperation will not end at the delivery . we believe that satisfied after sale service means a lot.

|

|

|

|

||||

|

* Inspected by the Sellers

|

After completing the manufacturing and assembling of the equipments, we will test the machines and commissioning in the workshop.

|

|

|

|

||||

|

* Inspected by the Buyers

|

After confirmation of a sound work of the line, we will invite our customer to send their representatives to inspect the production lines in our factories.

|

|

|

|

||||

1.Good quality: We have a professional designer and experienced engineer team.And the raw material and accessories we use are good.

2.Good service: we provide the technical support for whole life of our machines.

3.Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts.

4.Easy operation:All machine cotrolling by PLC computer controlling systerm.

5.Elegant apperance:Protect the machine from rust and the painted colour can be customized

6.Reasonable price:We offer the best price in our industry.

Recommend Products

Company

FAQ

1. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can produce more than 6 kinds of panels.

2. Do you have after sales support?

2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

3. What can you do if the machine broken?

3. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems and we supply the technical support for the whole life of the equipment.

4. Can you be responsible for transport?

4. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport

Hot Searches