- Product Details

- {{item.text}}

Quick Details

-

Power:

-

0.8

-

Weight:

-

520 kg

-

Dimension(L*W*H):

-

2500*935*1270

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Product name:

-

Self Cleaning Sludge Dewatering Screw Press

-

Brand origin:

-

Japan

-

Material:

-

SS304

-

Service life:

-

>15 years

-

Electrical components:

-

Schneider

-

Motor:

-

Bauer, Nissei, Sew

-

Application:

-

sludge dewatering, sewage treatment

-

Certificate:

-

ISO 9000, CE Certificate

-

Operate:

-

24 Hours Automatic

-

Certification:

-

ISO 9000, CE

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BENENV

-

Voltage:

-

380v

-

Power:

-

0.8

-

Weight:

-

520 kg

-

Dimension(L*W*H):

-

2500*935*1270

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Product name:

-

Self Cleaning Sludge Dewatering Screw Press

-

Brand origin:

-

Japan

-

Material:

-

SS304

-

Service life:

-

>15 years

-

Electrical components:

-

Schneider

-

Motor:

-

Bauer, Nissei, Sew

-

Application:

-

sludge dewatering, sewage treatment

-

Certificate:

-

ISO 9000, CE Certificate

-

Operate:

-

24 Hours Automatic

-

Certification:

-

ISO 9000, CE

MDS202, Self Cleaning Sludge Dewatering Screw Press

Comparison with Other Sludge Dewatering Machine

BENENV's MDS dewatering screw press is of unique dewatering structure. It has many advantages over traditional sludge dewatering machine: (under 30kg-DS/hour)

|

Item |

MDS Self Clean Screw Press |

Belt Press |

Centrifuge |

Conventional Screw Press |

|

Low Concentration Sludge Dewatering |

Yes |

No |

No |

No |

|

24 hours auto running |

Yes |

No |

No |

No |

|

Footprint |

2.4 m 2 |

6.14 m 2 |

4.32 m 2 |

10.4 m 2 |

|

Power Consumption |

0.8 kW/h |

1.2 kW/h |

20.5 kW/h |

2 kW/h |

|

Rinsing Water |

0.064 m 3 /h |

4.6 m 3 /h |

2.5 m 3 /h |

0.5 m 3 /h |

|

Noise |

60 dB (Normal Talking) |

71 dB (Noisy Street) |

82.4 dB (Noisy Factory) |

68 dB |

|

Labor Intensity |

Low |

High |

Normal |

Normal |

|

Working Environment |

Clean |

Dirty |

Clean |

Clean |

|

Maintenance |

Easy and Occasional |

Difficult and Frequent |

Difficult |

Difficult |

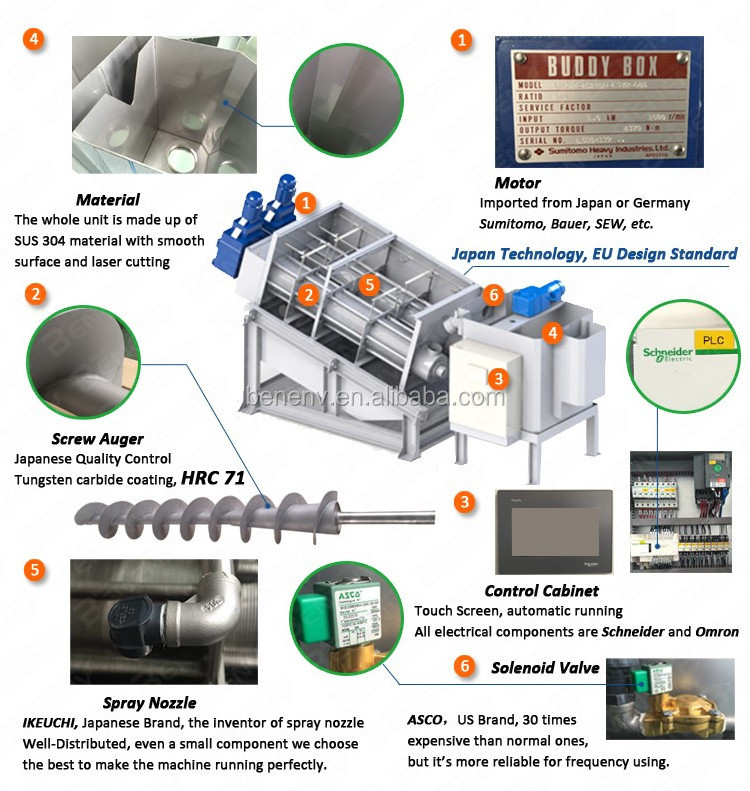

Product Structure

Dewatering Principle

BENENV® multi-disk screw press has a screw type cylinder that is much more advanced in very aspects than belt presses, Centrifuges, plate-and-frame filter presses, etc. It features clogging-free, wide range of applications, low energy consumption, simple operation & maintenance.

Thickening: When the shaft is driven by the screw, moving rings around the shaft move up and down relatively. Most water is pressed out from the thickening zone and fall down to the filtrate tank by gravity.

Dewatering: The thickened sludge moves forward continuously from the thickening zone towards the dewatering zone. With the pitch of the screw shaft thread getting narrower and narrower, the pressure in the filter chamber increases higher and higher. In addition to the pressure generated by the back-pressure plate, the sludge is greatly pressed and dryer sludge cakes produced.

Self-cleaning: The moving rings rotates continuously up and down under the pushing of the running screw shaft while the gaps between the fixed rings and moving rings are cleaned to prevent from clogging that happens frequently for traditional dewatering equipment.

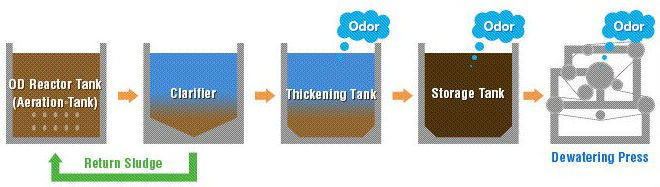

Dewater Sludge from Aeration Tank Directly

Built-in thickening zone allows MDS sludge dewatering screw press to directly dewater low-concentrated sludge from the aeration tank, eliminating the need for a thickening tank and a storage tank. Overall construction cost is greatly reduced than centrifuge, belt press and filter press.

Factory View

Projects

Patents

BENENV constantly focus on innovation & improvements of our products to meet the requirements of the market and provide our customers with products of reliability and high performance. So far, we've got dozens of patents and varieties of pending technologies on sludge treatment equipment.

Why Choose Us

1. BENEV has more than 2 decades experience in sludge treatment

2. We introduce Japanese technology and hire Japanese expert, thus our product is far more better than other Chinese manufacturer.

3. We only use the best parts from best supplier:

4. We have our own RD center and complete manufactuer system.

Our Clients

By 2015.06, 518 units of MDS Self Cleaning Sludge Dewatering Screw Press are installed in 37 countries!