- Product Details

- {{item.text}}

Quick Details

-

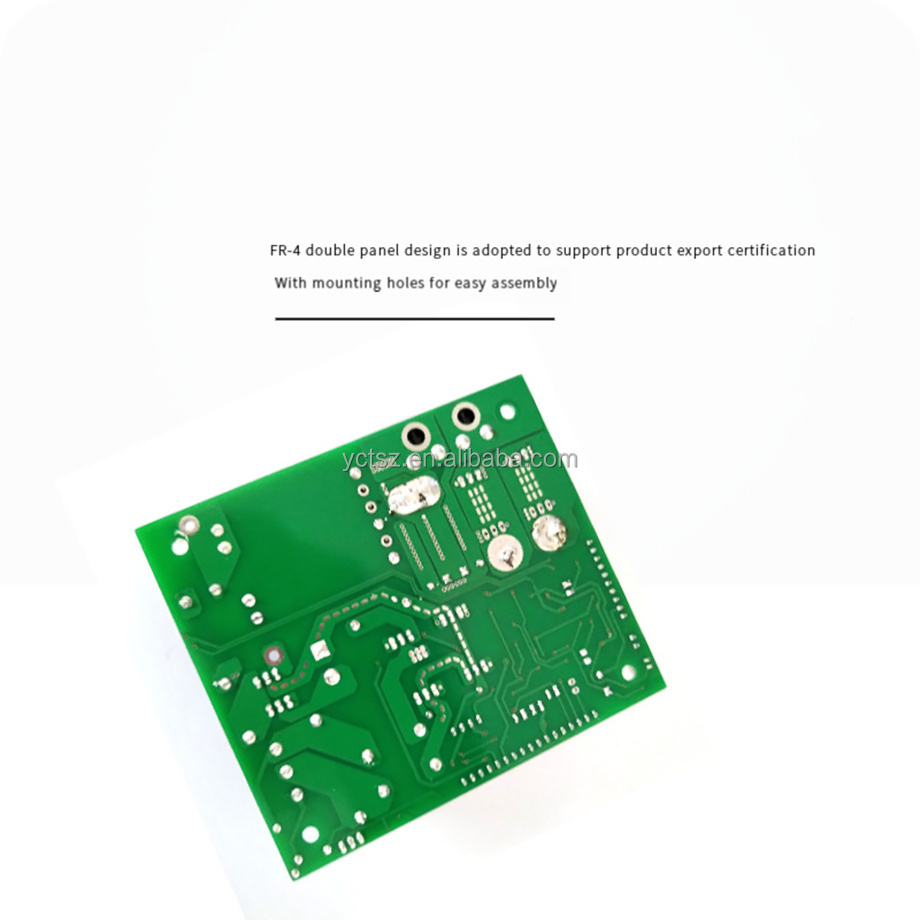

Base Material:

-

FR-4/aluminum/cem-1/cem-3/FR-1

-

Board Thickness:

-

1.6mm

-

Min. Hole Size:

-

0.10mm

-

Min. Line Width:

-

0.10mm

-

Min. Line Spacing:

-

0.1mm4mil

-

Surface Finishing:

-

HASL

-

Application:

-

consumer electronics

-

Certificate:

-

ROSH, ISO9001

-

Keywords:

-

home appliance

-

Coil Type:

-

Single Coil

Quick Details

-

Model Number:

-

YCT23-TM157

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YCT

-

Base Material:

-

FR-4/aluminum/cem-1/cem-3/FR-1

-

Board Thickness:

-

1.6mm

-

Min. Hole Size:

-

0.10mm

-

Min. Line Width:

-

0.10mm

-

Min. Line Spacing:

-

0.1mm4mil

-

Surface Finishing:

-

HASL

-

Application:

-

consumer electronics

-

Certificate:

-

ROSH, ISO9001

-

Keywords:

-

home appliance

-

Coil Type:

-

Single Coil

Product Description

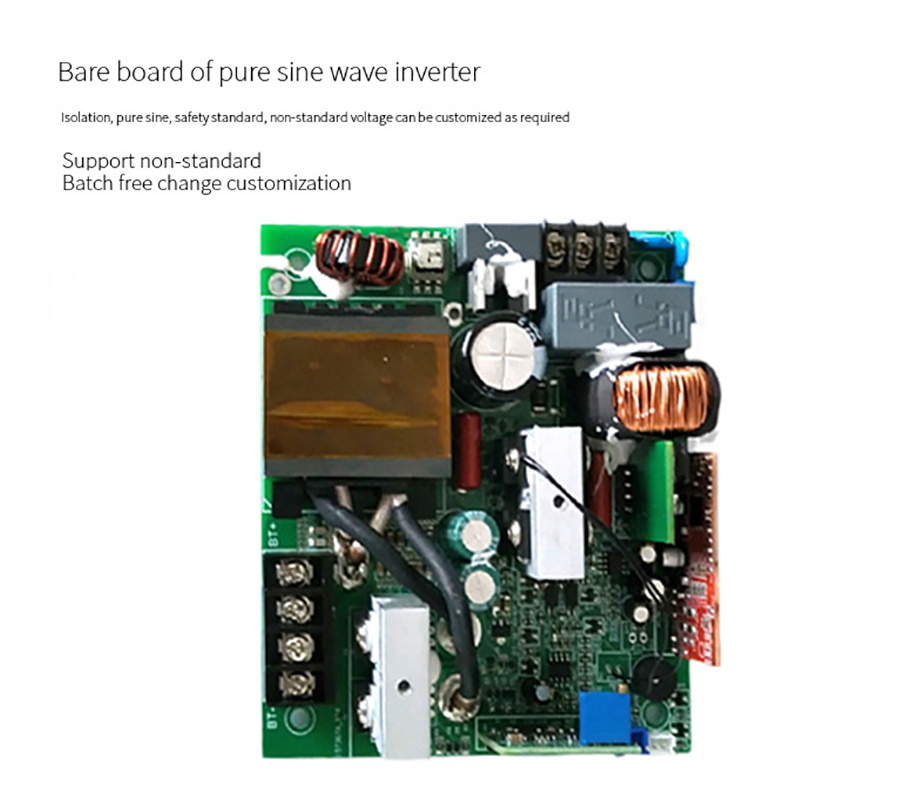

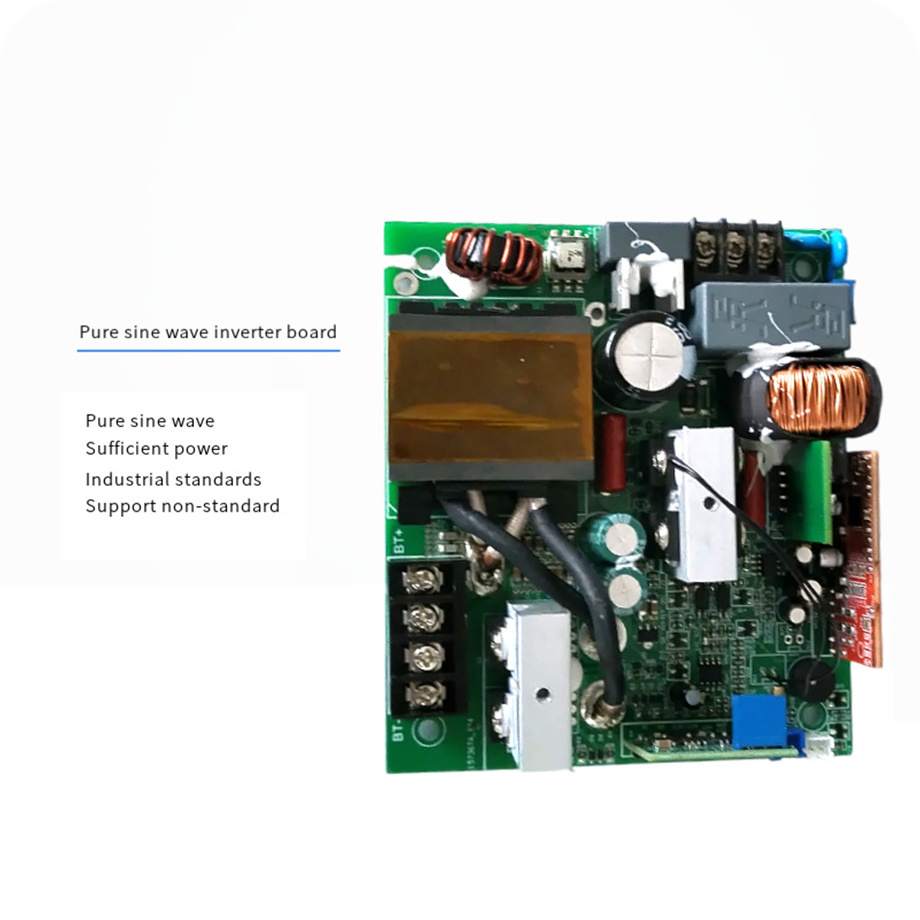

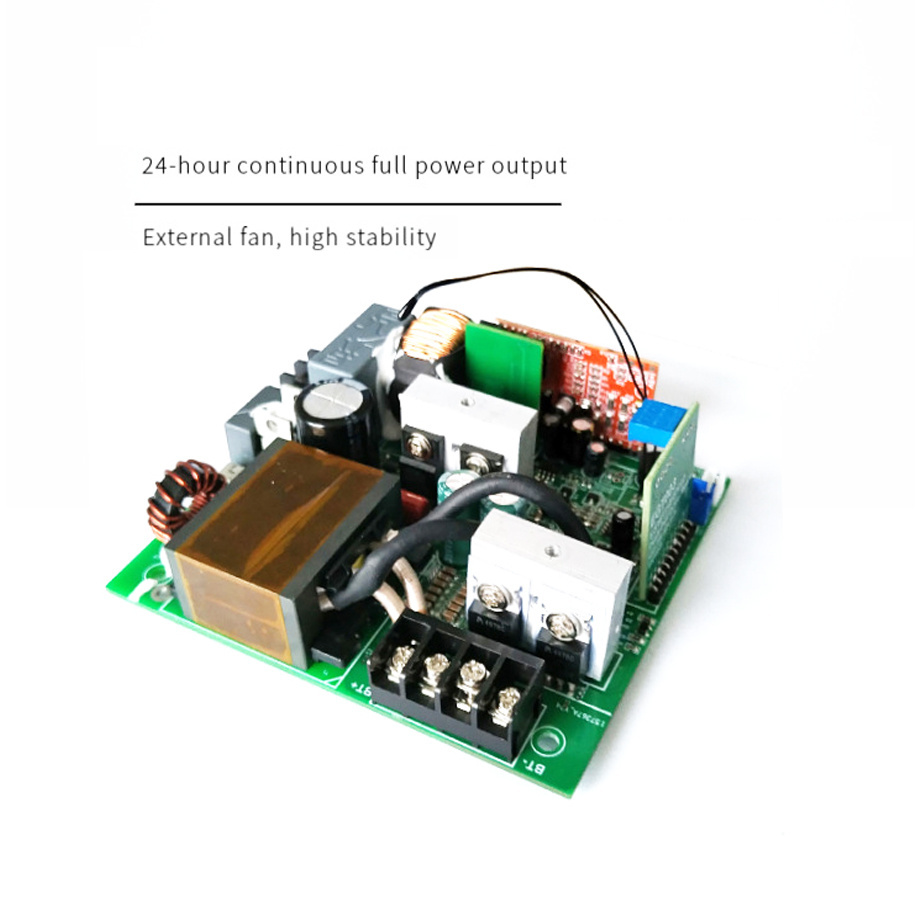

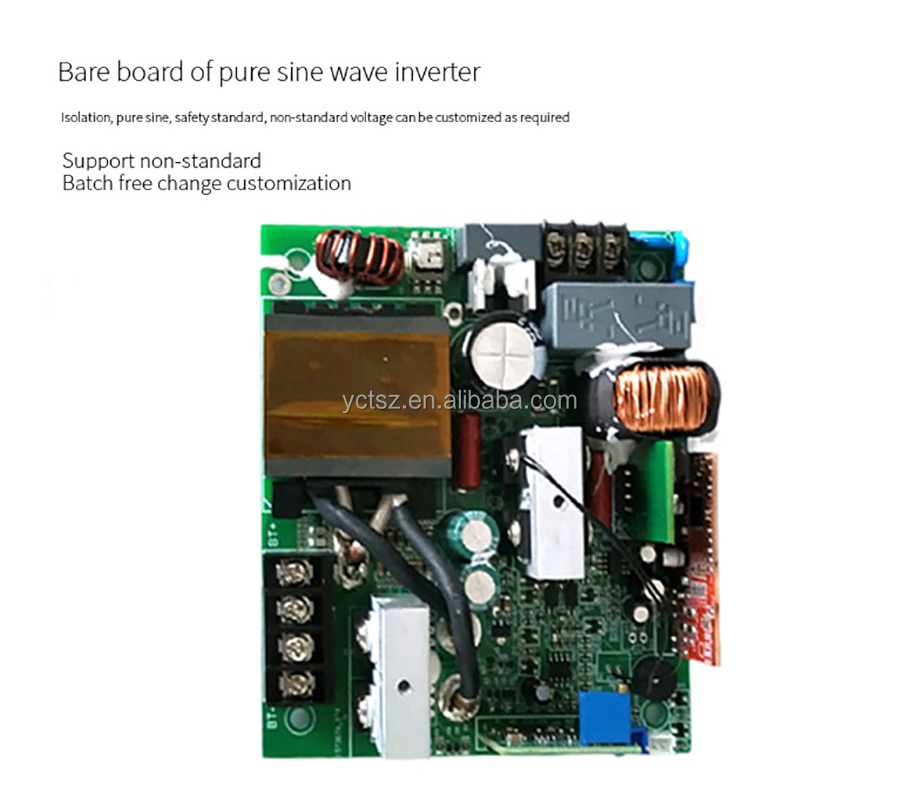

PCBA Assembly Factory Pure Sine Wave Inverter Circuit DC 12V To AC 220V 300W Inverter Board

Features:

* DC-AC Power Inverter

* 12V or 24V DC input

* Power ON-OFF switch

* Input voltage range: -15% ~ +25%

* Output voltage regulation: ±10%

* Protections: Bat. Low alarm / Bat. Low shutdown / Over voltage / Over temp./ Output short / Input polarity reverse / Over load.

* Output waveform: Modified sine wave

* Cooling fan ON-OFF control

* Topology: Microprocessor

* Approvals: e13/ CE

* DC-AC Power Inverter

* 12V or 24V DC input

* Power ON-OFF switch

* Input voltage range: -15% ~ +25%

* Output voltage regulation: ±10%

* Protections: Bat. Low alarm / Bat. Low shutdown / Over voltage / Over temp./ Output short / Input polarity reverse / Over load.

* Output waveform: Modified sine wave

* Cooling fan ON-OFF control

* Topology: Microprocessor

* Approvals: e13/ CE

APPLICATIONS:

Home appliance, Power tools, Office and Portable equipment and Vehicle ...etc.

DC to AC Power Inverter PCBA

|

OUTPUT

|

SAFETY MODEL NO.

|

TM300W

|

|

|

||

|

|

AC VOLTAGE

|

110V

|

230V

|

|

||

|

|

RATED POWER

|

300W

|

|

|

||

|

|

SURGE POWER

|

600W

|

|

|

||

|

|

WAVEFORM

|

Modified Sine Wave

|

|

|

||

|

|

FREQUENCY

|

60Hz ±1%

|

50Hz ±1%

|

|

||

|

|

AC REGULATION

|

±10%

|

|

|

||

|

|

STANDARD RECEPTACLES

|

TYPE-2* 2ea

|

TYPE-3* 2ea

|

|

||

|

|

LED INDICATOR

|

Green LED for power on; Red LED for power failure status

|

|

|

||

|

INPUT

|

DC CURRENT

|

35A

|

15A

|

|

||

|

|

NO LOAD CURRENT DRAW

|

0.36A

|

0.2A

|

|

||

|

|

DC VOLTAGE

|

12V

|

24V

|

|

||

|

|

VOLTAGE RANGE

|

10 ~ 15VDC

|

21 ~ 30VDC

|

|

||

|

|

EFFICIENCY (Typ.)

|

82%

|

85%

|

|

||

|

|

DC CONNECTOR

|

Battery clip*1ea

|

|

|

||

|

|

FUSE

|

Battery cord 35 A * 1, Cigarette plug 15 A* 1

|

Battery cord 20 A * 1, Cigarette plug 10 A* 1

|

|

||

|

PROTECTION

|

BAT. LOW ALARM

|

10±0.5V

|

20± 0.8V

|

|

||

|

|

BAT. LOW SHUTDOWN

|

9.5 ±0.5V

|

19.5± 0.8V

|

|

||

|

|

OVER LOAD

|

>1200W shut down o/p voltage, re-power to recover

|

|

|

||

|

|

OVER VOLTAGE

|

15 ~ 17V

|

30 ~ 32V

|

|

||

|

|

OVER TEMPERATURE

|

45 ± 5°C 113±9°F

|

|

|

||

|

|

OUTPUT SHORT

|

Shut-off

|

|

|

||

|

|

WORKING TEMP.BAT. POLARITY

|

By fuse open

|

|

|

||

|

ENVIRONMENT

|

WORKING TEMP.

|

0 ~ +30°C @ 100% load ; +40°C @ 50% load

|

|

|

||

|

|

WORKING HUMIDITY

|

20% ~ 90% RH non-condensing

|

|

|

||

|

|

STORAGE TEMP. HUMIDITY

|

30 ~ +70°C / -22 ~ +158 °F 10 ~ 95% RH

|

|

|

||

|

|

TEMP. COEFFICIENT

|

±0.05%/ °C/ (0 ~ 50°C )

|

|

|

||

|

SAFETY & EMC

|

ISOLATION RESISTANCE

|

I/P-O/P:100M Ohms / 500VDC / 25°C / 70%RH

|

|

|

||

|

|

EMI CONDUCTION & RADIATION

|

Compliance to EN55022 class B, 72/ 245/ CEE, 95/ 54/ CE

|

|

|

||

|

|

EMC IMMUNITY

|

Compliance to EN61000-4-2,3

|

|

|

||

|

|

LVD

|

Compliance to EN60950

|

|

|

||

|

|

MTBF

|

200Khrs min. MIL-HDBK-217F (25°C)

|

|

|

||

|

Medical PCBA Production Capacity

|

|

|

|

|

||||

|

Types of PCB assembly

|

|

SMT (Surface Mounted Technology)

|

|

|

||||

|

|

|

THT (Through Hole Technology)

|

|

|

||||

|

|

|

Mixed (surface mount and through hole) technology

|

|

|

||||

|

|

|

Cable assembly

|

|

|

||||

|

Components

|

|

Passive Component: small as 01005, 0201

|

|

|

||||

|

|

|

BGA, uBGA, QFN, POP, SOP,SSOP,PLCC,LGA

|

|

|

||||

|

|

|

Fine Pitch Parts: 0.25mm fine pitch parts

|

|

|

||||

|

|

|

Max Component Height: 25mm(SMT), Top 120mm/Bot 15mm (Wave-Solder)

|

|

|

||||

|

Component Package

|

|

Reels, cut tape, Tube and tray, Loose parts and bulk

|

|

|

||||

|

Board Dimension

|

|

Min Board Size: No Limited

|

|

|

||||

|

|

|

Max Board Size: 680 x 500mm

|

|

|

||||

|

Board Shape

|

|

We can assemble boards in Rectangular, Circular and irregular

|

|

|

||||

|

Board Type

|

|

Rigid PCB, Flexible PCB, Rigid-flex PCB

|

|

|

||||

|

Assembly process

|

|

Lead-Free (RoHS)

|

|

|

||||

|

Design file format

|

|

Gerber RS-274X

|

|

|

||||

|

|

|

BOM (Bill of Materials) (.xls, .csv, . xlsx)

|

|

|

||||

|

|

|

Centroid(Pick-N-Place/XY file)

|

|

|

||||

|

Electrical testing

|

|

X-ray Inspection

|

|

|

||||

|

|

|

AOI (Automated Optical Inspection)

|

|

|

||||

|

|

|

Functional testing

|

|

|

||||

|

Certificate

|

|

ISO13485, IATF16949, ISO9001,ISO14001

|

|

|

||||

|

Quality Standards

|

|

IPC-A-600/IPC-A-610 compliance

|

|

|

||||

|

Type of Service

|

|

Turn-key, partial turn-key or consignment

|

|

|

||||

Our products used in various fields such as consumer electronics, industrial control, telecommunication, computer and medical. Wedo not only offer the simple Fr4 PCB but also Alu PCB, Ceramic ALN and AL2O3, metal and copper base PCB, Rigid-flex board, heavycopper and etc.

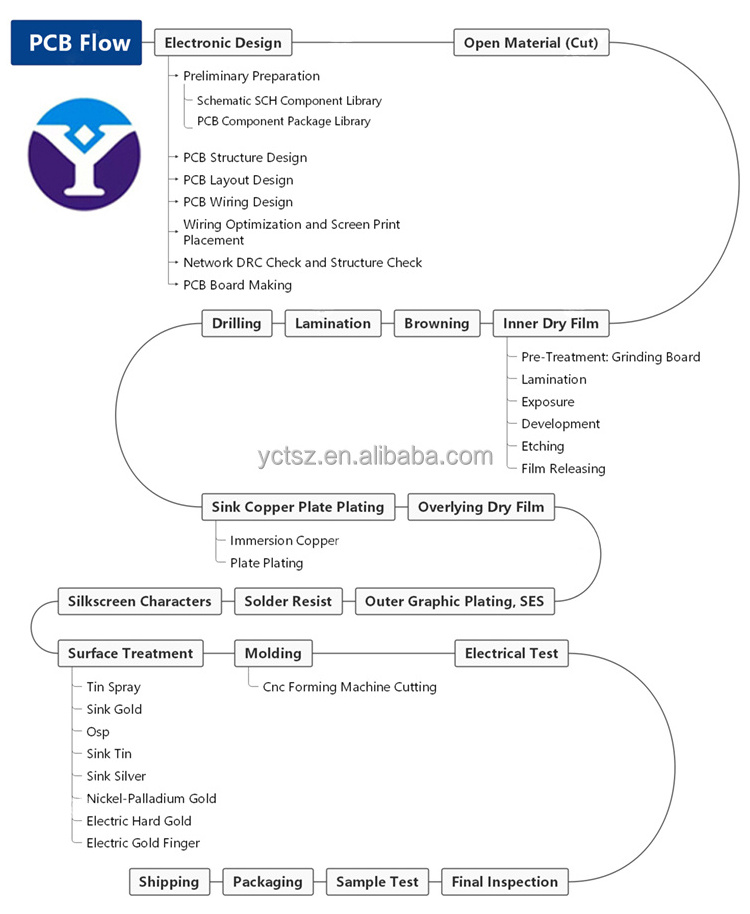

Specification

|

PCB Techinecal Capacity

|

|

|

|

|

||||

|

Layers

|

|

Mass production: 2~58 layers / Pilot run: 64 layers

|

|

|

||||

|

Max. Thickness

|

|

Mass production: 394mil (10mm) / Pilot run: 17.5mm

|

|

|

||||

|

Materials

|

|

FR-4 (Standard FR4, Mid-Tg FR4,Hi-Tg FR4, Lead free assembly material) , Halogen-Free, Ceramic filled , Teflon, Polyimide, BT,PPO,

PPE, Hybrid, Partial hybrid, etc |

|

|

||||

|

Min. Width/Spacing

|

|

Inner layer: 3mil/3mil (HOZ), Outer layer: 4mil/4mil(1OZ)

|

|

|

||||

|

Max. Copper Thickness

|

|

6.0 OZ / Pilot run: 12OZ

|

|

|

||||

|

Min. Hole Size

|

|

Mechanical drill: 8mil(0.2mm) Laser drill: 3mil(0.075mm)

|

|

|

||||

|

Surface Finish

|

|

HASL,Immersion Gold, Immersion Tin, OSP, ENIG + OSP, Immersion Silver, ENEPIG, Gold Finger

|

|

|

||||

|

Special Process

|

|

Buried Hole, Blind Hole, Embedded Resistance, Embedded Capacity, Hybrid, Partial hybrid, Partial high density, Back drilling, and

Resistance control |

|

|

||||

|

PCBA technical Capacity

|

|

|

|

|

||||

|

Advantages

|

|

----Professional Surface-mounting and Through-hole soldering technology

|

|

|

||||

|

|

|

----Various sizes like 1206,0805,0603 components SMT technology

|

|

|

||||

|

|

|

----ICT(In Circuit Test),FCT(Functional Circuit Test)

|

|

|

||||

|

|

|

----PCB Assembly With UL,CE,FCC,Rohs Approval

|

|

|

||||

|

|

|

----Nitrogen gas reflow soldering technology for SMT.

|

|

|

||||

|

|

|

----High Standard SMT&Solder Assembly Line

|

|

|

||||

|

|

|

----High density interconnected board placement technology capacity.

|

|

|

||||

|

Components

|

|

Passive Down to 0201 size, BGA and VFBGA, Leadless Chip Carriers/CSP

|

|

|

||||

|

|

|

Double-sided SMT Assembly, Fine Pitch to 0.8mils, BGA Repair and Reball

|

|

|

||||

|

Testing

|

|

Flying Probe Test,X-ray Inspection AOI Test

|

|

|

||||

|

SMT

|

|

Position accuracy: 20 um

|

|

|

||||

|

|

|

Components size: 0.4×0.2mm(01005) —130×79mm, Flip-CHIP, QFP, BGA, POP

|

|

|

||||

|

|

|

Max. component height: 25mm

|

|

|

||||

|

|

|

Max. PCB size: 680×500mm

|

|

|

||||

|

|

|

Min. PCB size: no limited

|

|

|

||||

|

|

|

PCB thickness: 0.3 to 6mm

|

|

|

||||

|

Wave-Solder

|

|

Max. PCB width: 450mm

|

|

|

||||

|

|

|

Min. PCB width: no limited

|

|

|

||||

|

|

|

Component height: Top 120mm/Bot 15mm

|

|

|

||||

|

Sweat-Solder

|

|

Metal type: part, whole, inlay, sidestep

|

|

|

||||

|

|

|

Metal material: Copper, Aluminum

|

|

|

||||

|

|

|

Surface Finish: plating Au, plating sliver, plating Sn

|

|

|

||||

|

|

|

Air bladder rate: less than 20%

|

|

|

||||

|

Press-fit

|

|

Press range: 0-50KN

|

|

|

||||

|

|

|

Max. PCB size: 800X600mm

|

|

|

||||

Packing & Delivery

Vacuum Packing with Carton Box

Hot Searches