- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

RT

-

Model Number:

-

ZD350RT

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3.5m*1.4m*1.8m

-

Weight:

-

850 KG

-

Showroom:

-

Egypt, Viet Nam, India, Mexico

-

Key Slling Points:

-

Automatic

-

Markeing Type:

-

New Product 2021

-

Certification:

-

CE

-

Product name:

-

Handle Brown Paper Bag Making Machine

-

Suitable material:

-

Kraft Paper Roll

-

Function:

-

square bottom, handle loop

Quick Details

-

Machine Type:

-

SEALING MACHINE

-

Bag Type:

-

Shopping Bag

-

Material:

-

Paper

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

RT

-

Model Number:

-

ZD350RT

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3.5m*1.4m*1.8m

-

Weight:

-

850 KG

-

Showroom:

-

Egypt, Viet Nam, India, Mexico

-

Key Slling Points:

-

Automatic

-

Markeing Type:

-

New Product 2021

-

Certification:

-

CE

-

Product name:

-

Handle Brown Paper Bag Making Machine

-

Suitable material:

-

Kraft Paper Roll

-

Function:

-

square bottom, handle loop

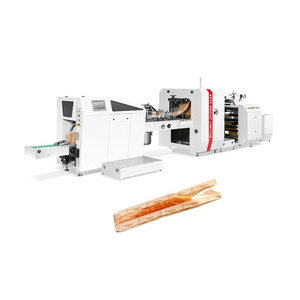

Products Description

Automatic square bottom

handle

paper bag making machine

Sumary

Fully automatic square bottom paper bag machine is used to produce hand-held paper bags with hand handles. This machine is especially suitable for the bulk production of shopping bags in food and clothing industries.

Main Feature:

1. Using Willon touch screen man-machine interface, the operation function is clear at a glance, easy to control.

2. Adopt the Japanese original Mitsubishi motion controller, through the integration with the optical fiber, operation stability.

3. Japanese Mitsubishi servo motor with German Schick color standard eye correction, accurate tracking printing bag size

4. The raw material loading and unloading adopts hydraulic dynamic lifting structure, and the unwinding adopts automatic constant tension control.

5. The raw material correction adopts brushless servo motor to reduce the adjustment time of paper roll alignment.

2. Adopt the Japanese original Mitsubishi motion controller, through the integration with the optical fiber, operation stability.

3. Japanese Mitsubishi servo motor with German Schick color standard eye correction, accurate tracking printing bag size

4. The raw material loading and unloading adopts hydraulic dynamic lifting structure, and the unwinding adopts automatic constant tension control.

5. The raw material correction adopts brushless servo motor to reduce the adjustment time of paper roll alignment.

Specification

|

Model

|

ZD350RT

|

|

Bag width

|

120-350mm

|

|

Bag length

|

270-530mm

|

|

Bag thickness

|

80-150GSM

|

|

Speed

|

30-180pcs/min

|

|

Power

|

380V/ 50HZ, 3Phase 41.5kw

|

|

Weight

|

15000kg

|

|

Machine Dimension

|

14000*6000*2400mm

|

Samples

Hot Searches