- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

3.43*2.3*2.65

-

Screw diameter (mm):

-

70 mm

-

Screw Heating Power(kW):

-

8 kW

-

Extruder Motor Power(kW):

-

22 kW

-

Mold Platen Size(Width)(mm):

-

148 mm

-

Mold Platen Size(Height)(mm):

-

508 mm

-

Air Pressure(MPa):

-

0.6 MPa

-

Air Comsumption(m³/min):

-

0.4 m³/min

-

Die Head Heating Power(kW):

-

2.5 kW

-

Accumulator Capacity(L):

-

5 L

-

Power (kW):

-

50

-

Weight (T):

-

4

-

MAX.Product Volume:

-

5L

-

Station:

-

double

-

Output of HDPE:

-

70kg/h

-

Blowing pressure:

-

0.6Mpa

-

Air consumption:

-

0.4M3/Min

-

Cooling water pressure:

-

0.3Mpa

-

Water consumption:

-

60L/Min

-

Model Number:

-

HTII-5L

-

Weight:

-

5.5ton

-

Power(W):

-

7.5kw

Quick Details

-

Clamping Force (kN):

-

65

-

Output (kg/h):

-

70 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

3.43*2.3*2.65

-

Screw diameter (mm):

-

70 mm

-

Screw Heating Power(kW):

-

8 kW

-

Extruder Motor Power(kW):

-

22 kW

-

Mold Platen Size(Width)(mm):

-

148 mm

-

Mold Platen Size(Height)(mm):

-

508 mm

-

Air Pressure(MPa):

-

0.6 MPa

-

Air Comsumption(m³/min):

-

0.4 m³/min

-

Die Head Heating Power(kW):

-

2.5 kW

-

Accumulator Capacity(L):

-

5 L

-

Power (kW):

-

50

-

Weight (T):

-

4

-

MAX.Product Volume:

-

5L

-

Station:

-

double

-

Output of HDPE:

-

70kg/h

-

Blowing pressure:

-

0.6Mpa

-

Air consumption:

-

0.4M3/Min

-

Cooling water pressure:

-

0.3Mpa

-

Water consumption:

-

60L/Min

-

Model Number:

-

HTII-5L

-

Weight:

-

5.5ton

-

Power(W):

-

7.5kw

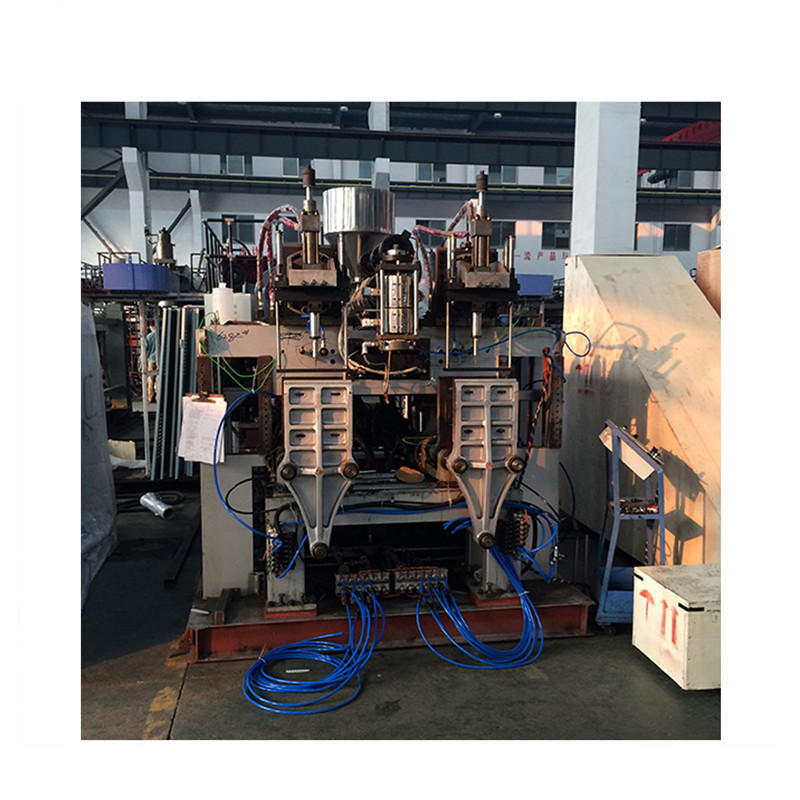

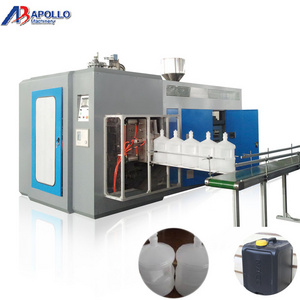

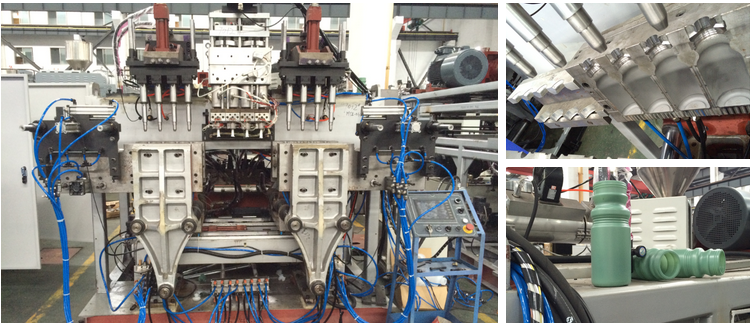

extrusion blow molding / moulding machine One step good price auto 5 gallon 20 liter pc hdpe abs automatic plastic water bottle

It is suitable for producing plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, pesticide bottle oil bottle cosmetics, wide-mouth bottle etc. Beverage bottle, cosmetic bottle, medicine bottle, jar,drum ,Tool kit , plastic model etc.

B:The other parts

Jerry Can Blow Moulding Machine

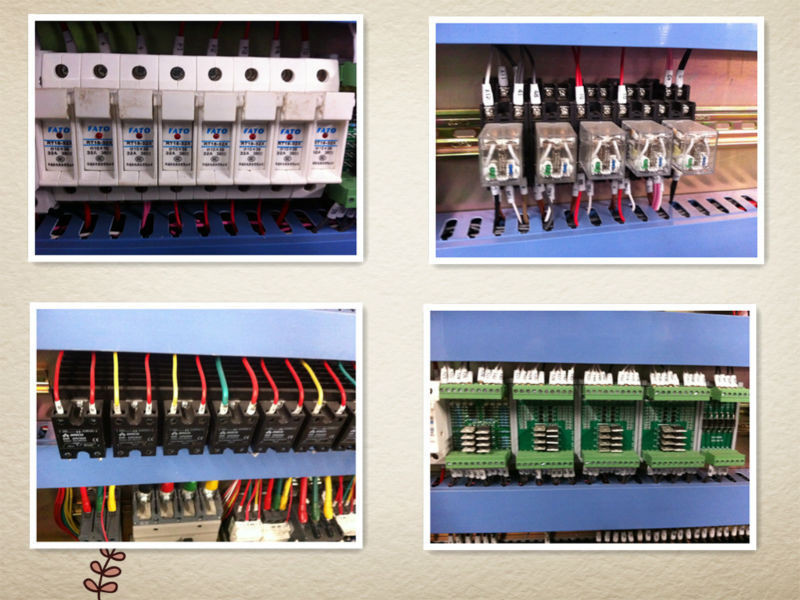

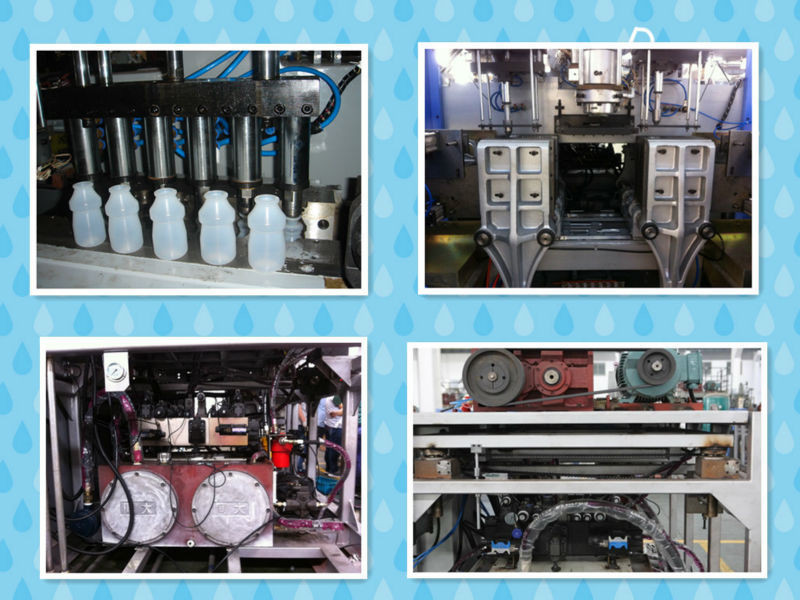

Proportional pressure control equipped with hydraulic valve and pump imported brand-name, stable and reliable.

100-point electro-hydraulic servo control systems, electro-hydraulic servo system uses the energy storage device.

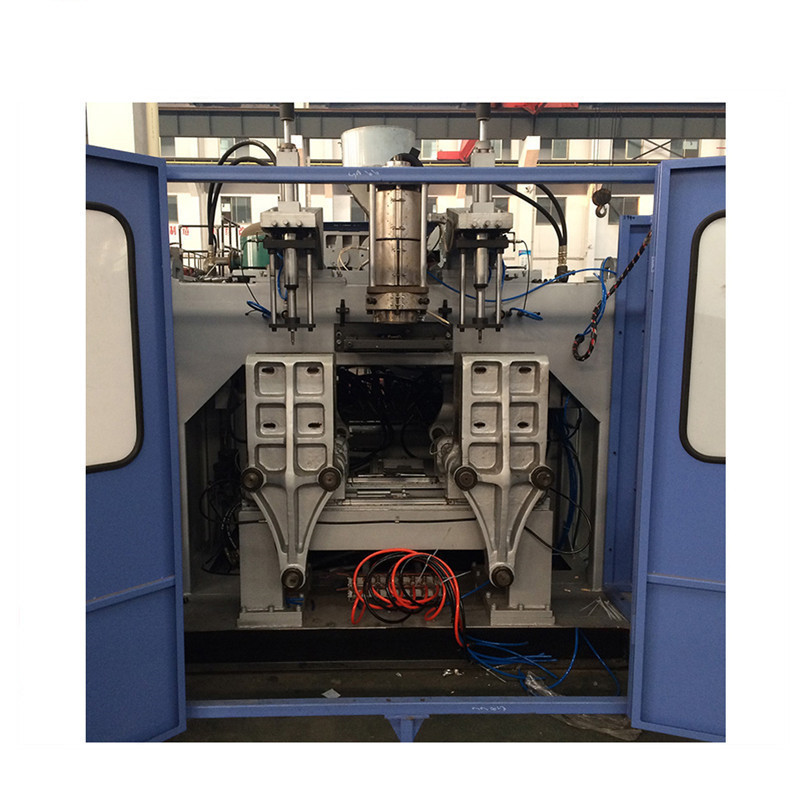

C:The opening and closing mold

Jerry Can Blow Moulding Machine

the use of two template pin lock mechanism, the bottom of the template model using linear guide cylinder to achieve the shift shift mode, clamping force and balanced, enabling micro-mold, thus ensuring the locking time clamping force is sufficient, when mold mold smooth. This pin lock mechanism has been applied for a patent.

D: Extrusion blow molding machine installation, commissioning and training:

Jerry Can Blow Moulding Machine

If the buyer needs seller to send technicians to workshop for supervising the erection and start-up, seller must support and send sufficient number of technicians and keep duration of stay in workshop. Usually it's about 3~5 days in this duration. The first day is that when our technician is at the airport to factory of buyer. And from the first day, the buyer has to pay US$80 per day. And all accommodation, visa application & air ticket will be born by the buyer.

E:Our products

Jerry Can Blow Moulding Machine

Main Features

1) Simple structure in linear type ,easy in installation .

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

1> The machine will be tested and checked at our workshop before delivery.

2>After one year, we will supply accessories are provided only one the cost price.

3>Free production technology and process configuration.

4>Installation: Experts’ team to buyer’s country after confirmation that the goods arrived in site and civil works completed get ready for installation. Funds for trip need to be payed by client and extra salary $60/day during the engineer’s journey.

5>Warranty: One year from the date of Installation or acceptance of the Plant whichever comes first

6>We will reply you within 24 hours

Suzhou Mould Co., LTD is located in zhangjiagang city TangQiao economic development zone and the traffic is developed.

The company fusion technology, Western Europe professional design and production, sales three categories and 23 kinds of series and one hundred and eighteen kinds of specifications and types of automatic bottle blowing machines, blow molding blow molding machines and the company is in jiangsu province beverage, plastic machinery enterprise one of the export base.

The company product widely sales Britain, Australia, Brazil and 55 countries and the area, deeply trusted by customers domestic and abroad.

extrusion blow molding / moulding machine One step good price auto 5 gallon 20 liter pc hdpe abs automatic plastic water bottle