- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380/220V 50H

-

Power:

-

3.5KW

-

Dimension(L*W*H):

-

1250mm*650mm*800mm

-

Weight (KG):

-

500

-

Marketing Type:

-

New Product 2023

-

Evaporation Capacity(kg/h):

-

200mL/H ~ 2000ml/h

-

Name:

-

Spray dryer

-

Function:

-

Multi-function

-

Usage:

-

Drying Wet Raw Material

-

Feature:

-

Low Energy High Efficiency

-

MOQ:

-

1 Set

-

Temperature range:

-

30 ℃ -300℃

-

Average drying time:

-

0.8-1.5S

-

Fuel:

-

Electricty

-

Dryig process:

-

Continuous Automatic Drying

Quick Details

-

Type:

-

Spray Drying Equipment

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

OCEAN

-

Voltage:

-

380/220V 50H

-

Power:

-

3.5KW

-

Dimension(L*W*H):

-

1250mm*650mm*800mm

-

Weight (KG):

-

500

-

Marketing Type:

-

New Product 2023

-

Evaporation Capacity(kg/h):

-

200mL/H ~ 2000ml/h

-

Name:

-

Spray dryer

-

Function:

-

Multi-function

-

Usage:

-

Drying Wet Raw Material

-

Feature:

-

Low Energy High Efficiency

-

MOQ:

-

1 Set

-

Temperature range:

-

30 ℃ -300℃

-

Average drying time:

-

0.8-1.5S

-

Fuel:

-

Electricty

-

Dryig process:

-

Continuous Automatic Drying

Product Description

Introduction

The experimental spray dryer (small spray dryer) is compact in design and can be independently placed in the laboratory or on a specially designed stainless steel rack. It is self-contained and can operate without other facilities. One click startup, color large LCD touch screen operation, can adopt two operation modes: fully automatic or manual monitoring, convenient for operation and monitoring of the experimental process. It is a spray dryer with the smallest volume, smallest noise and excellent drying effect.

Application

1. Organic Chemistry of Food, Milk Powder, Egg Yolk, Soy Sauce, Coffee, Starch, Protein, Spices, and Extracts

2. Inorganic chemistry fields, such as wax, dyes, detergents, synthetic resins, pigments, etc

3. Various fuel cell development fields for automotive and ship propulsion, including ferrite, ceramics, photocopying powders, magnetic materials, metal powders, etc

Features

1. The design of drying temperature control adopts real-time constant temperature control technology, ensuring accurate

temperature control in the entire temperature range and heating temperature control accuracy of ± 1 ℃

temperature control in the entire temperature range and heating temperature control accuracy of ± 1 ℃

2. The feeding amount can be adjusted through the feeding peristaltic pump, and the small sample quantity can reach 50ml.

3. The dried finished dry powder has a relatively uniform particle size, with over 98% of the dry powder within the same particle size range.

4. For viscous materials,there is a nozzle cleaner that automatically clears when the nozzle is blocked, and the frequency of needle passage can be automatically adjusted.

5. Innovative tower wall blowing device with higher material recovery rate.

6. Unique protection function, with fan not starting, heating not starting, and adjustable fan air volume.

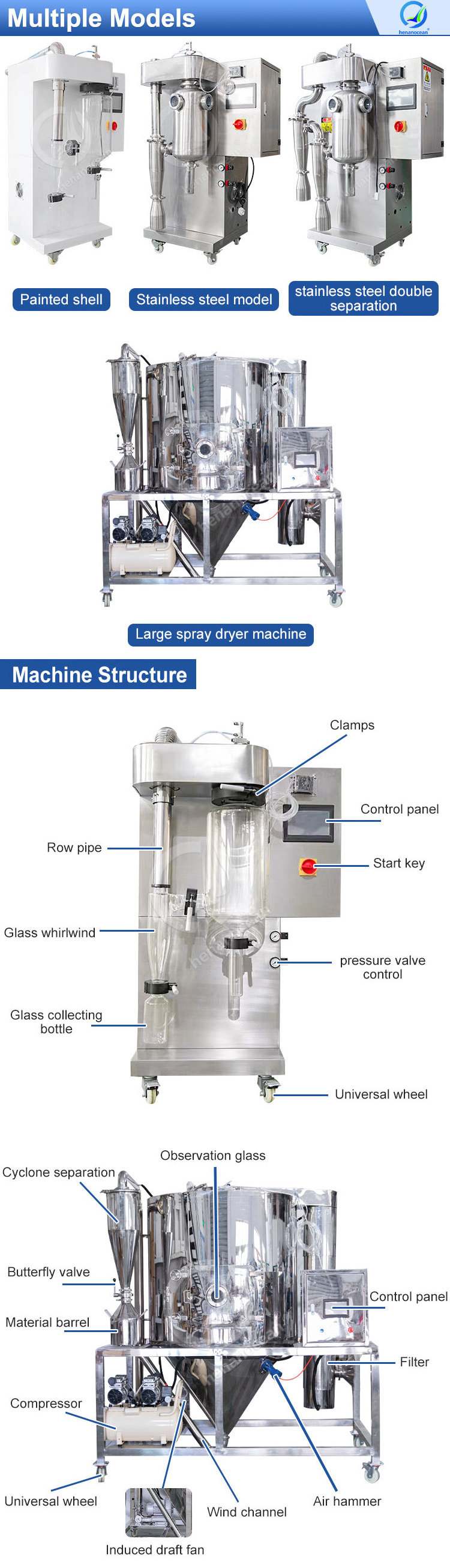

Structure

|

Inlet air temperature

|

30-300 ℃

|

Outlet air temperature

|

30-150 ℃

|

|

Evaporation water volume

|

1500mL/H-2000ml/h

|

Maximum feed rate

|

2000mL/H

|

|

Minimum feed rate

|

50Ml

|

Nozzle diameter

|

1.00mm

|

|

Average drying time:

|

1.0~1.5S

|

Air compressor

|

0.2KW

|

|

maximum gas production

|

4.2 m3/h

|

Working pressure

|

2-3Bar

|

Production Details

Related Products

Packing & Shipping

Install waterproof membrane to reduce dust and water pollution

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation

Hot Searches