- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

39 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hanhai

-

Voltage:

-

as per customers` requirement

-

Dimension(L*W*H):

-

25m*2.5m*3m (L*W*H)

-

Power (kW):

-

100

-

Weight:

-

8 -15ton

-

Name:

-

Pvc Tube Extrusion Line

-

Motor:

-

Siemens

-

PLC:

-

Siemens

-

Inverter:

-

ABB or Delta brand

-

Contactor brand:

-

Siemens Bede

-

Temperature controller:

-

Omron brand

-

Product Type:

-

All kinds of PVC pipes

-

Cooling way:

-

Recycling Water Cooling

-

Features:

-

Competitive price/Long service life/High-accuracy

-

Certification:

-

CE

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw diameter (mm):

-

65 mm

-

Screw Speed (rpm):

-

39 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hanhai

-

Voltage:

-

as per customers` requirement

-

Dimension(L*W*H):

-

25m*2.5m*3m (L*W*H)

-

Power (kW):

-

100

-

Weight:

-

8 -15ton

-

Name:

-

Pvc Tube Extrusion Line

-

Motor:

-

Siemens

-

PLC:

-

Siemens

-

Inverter:

-

ABB or Delta brand

-

Contactor brand:

-

Siemens Bede

-

Temperature controller:

-

Omron brand

-

Product Type:

-

All kinds of PVC pipes

-

Cooling way:

-

Recycling Water Cooling

-

Features:

-

Competitive price/Long service life/High-accuracy

-

Certification:

-

CE

Product Description

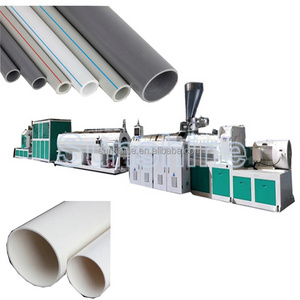

16-1000 mm Plastic PVC Water Supply Drainage Pipe Electric Protection Tube Making Machine

We are very professional in producing the PVC pipe production line. We have stock in our factory, you can come to visit at any time.

The whole production line consists of the following seven parts:

|

NO.

|

Name

|

Quantity

|

|

1

|

Conical double screw extruder with automatic feeding system

|

1set

|

|

2

|

Mould

|

1set

|

|

3

|

Vacuum calibrating and cooling tank

|

1set

|

|

4

|

Haul-off machine

|

1set

|

|

5

|

Cutting machine

|

1set

|

|

6

|

Stacker

|

1set

|

|

7

|

Belling machine (optional)

|

1set

|

Details Images

1.

PVC Pipe Electric Making Machine

Conical double screw extruder with automatic feeding system:

According to the requirements of different diameters, different wall thicknesses and different output of pipes, we have many models of special twin screw extruders to choose from. It adopts a specially designed screw structure, which can evenly heat, plasticize PVC powder and extrude pipes .

(1) Motor brand: Siemens

(2) Inverter brand: Delta

(3) Contactor brand: Siemens

(4) Relay brand: Omron

(5) Breaker brand: Schneider

(6) Material of screw and barrel: 38CrMoAlA.

(7) Heating method: Ceramic or cast aluminum heating

2.

PVC Pipe Electric Making Machine

Mould:

The mould is made of high-quality alloy steel, the internal flow channel is chrome-plated and highly polished, which is wear-resistant and corrosion-resistant; With the special sizing sleeve, the product production speed is hight and the surface of the pipe is good.

(1) Material: 40GR

(2) Size: Customized

3.

PVC Pipe Electric Making Machine

Calibrating and cooling tank:

The calibrating and cooling tank can calibrate and cool the PVC pipe from the mould.

(1) Vacuum pump power : 4 kw

(2) Water pump power: 2.2 kw*2

(3) Spray cooling: ABS nozzle; Stainless steel pipe

(4) Stainless steel material: 1Cr18NiTi

(5) Diameter of tank : Customized

(6) Length of tank: 6 m

(3) Spray cooling: ABS nozzle; Stainless steel pipe

(4) Stainless steel material: 1Cr18NiTi

(5) Diameter of tank : Customized

(6) Length of tank: 6 m

4.

PVC Pipe Electric Making Machine

Haul-off machine

The haul-off machine can transport PVC pipe to cutting machine.

(1) Hauling power: 1.5 kw

(2) Clamping style: Pneumatic clamping

(3) Transducer: Siemens transducer

(4) Hauling track type: Plastic block

(5) Effective clamping length 1800 mm

5.

PVC Pipe Electric Making Machine

Cutting machine:

The special cutting machine for PVC pipe adopts rotary clamping device, is suitable for different pipe diameters, avoids the trouble of frequently changing clamping device.

(1) Cutting motor power: 1.5 kw

(2) Cutting scope: Customized

(3) Control means: Pneumatic control

6.

PVC Pipe Electric Making Machine

Stacker:

It is used to hold pipes and can unload pipes automatically.

(1) Length: 6000 mm

(2) Material: Stainless steel

(3) Unloading method: Pneumatic unloading

(3) Unloading method: Pneumatic unloading

7.

PVC Pipe Electric Making Machine

Belling machine (optional)

Belling machine can expand one end of the PVC pipe into the specified shape.

|

Extruder Model

|

Pipe Diameter

(mm)

|

Production Capacity

(kg/h)

|

Production Speed (m/min)

|

Total Power

(kw/h)

|

|

SJSZ51/105

|

16~63

|

120

|

15

|

45

|

|

SJSZ55/110

|

50~160

|

180

|

5

|

55

|

|

SJSZ65/132

|

75~250

|

250

|

4

|

75

|

|

SJSZ80/156

|

110~315

|

450

|

2

|

105

|

|

SJSZ92/188

|

315~630

|

600

|

1

|

205

|

|

Raw Material

|

Percentage

|

|

PVC resin powder

|

65%-90%

|

|

Calcium powder

|

0-26%

|

|

CPE

|

4%-6%

|

|

Compound stabilizer, Titanium dioxide,

Stearic acid, Paraffin, PE wax, etc.

|

5%

|

Final products

PVC Pipe Electric Making Machine You just tell me what machine you want,let us do the rest work:

1. Design and manufacture suitble machine for you.

2

. Before delivery, we will test the machine until you are completely satisfied. (You can come to our factory to inspect the running production line.)

3. Delivery.

4. We will provide after-sales service:

(1) Field installation

and

commissioning;

(2) Field training your workers;

(3) Field maintenance and repair service ;

(4) Free Spare Parts ;

(5) Video/Online technical support.

Reviews by customers

Certifications

Cooperation Brands

FAQ

1.Are you manufacturer or trading company?

We are manufacturer.

2.Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer's factory.

3.Delivery time: 20~30 days.

4.Payment terms:

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).

5.After-sales service:

Free Spare Parts ;

We are manufacturer.

2.Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer's factory.

3.Delivery time: 20~30 days.

4.Payment terms:

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).

5.After-sales service:

Free Spare Parts ;

Field installation, commissioning and training ;

Field maintenance and repair service ;

Video/Online technical support.

6.Warranty: 1 year.

Field maintenance and repair service ;

Video/Online technical support.

6.Warranty: 1 year.

Contact Us

Contact Person: Hans Liu

Phone/ Whatsapp/ Wechat : 0086 13188982007

QQ: 826967534

Email: hans@hanhaisuji.com

Hot Searches