- Product Details

- {{item.text}}

Quick Details

-

Productivity:

-

30-40M³/H

-

Place of Origin:

-

Shandong, China

-

Weight:

-

5800 kg

-

Dimension(L*W*H):

-

5800x2250x2300

-

Marketing Type:

-

Other

-

Product name:

-

Concrete Pump Mixer

-

Concrete pump type:

-

Reliable Concrete Pumping

-

Chassis:

-

stronger frame

-

Engine:

-

YU CHAI

-

Color:

-

Customers' Requirement

-

Max Aggregate Size:

-

20-40mm

-

Type:

-

JBT-40

-

Capacity:

-

40m3/hr

-

Application:

-

Construction Building Equipment

-

Motor Power:

-

66 KW

Quick Details

-

Power Type:

-

Diesel

-

Max. vertical conveying distance:

-

120M

-

Max. horizontal conveying distance:

-

500M

-

Productivity:

-

30-40M³/H

-

Place of Origin:

-

Shandong, China

-

Weight:

-

5800 kg

-

Dimension(L*W*H):

-

5800x2250x2300

-

Marketing Type:

-

Other

-

Product name:

-

Concrete Pump Mixer

-

Concrete pump type:

-

Reliable Concrete Pumping

-

Chassis:

-

stronger frame

-

Engine:

-

YU CHAI

-

Color:

-

Customers' Requirement

-

Max Aggregate Size:

-

20-40mm

-

Type:

-

JBT-40

-

Capacity:

-

40m3/hr

-

Application:

-

Construction Building Equipment

-

Motor Power:

-

66 KW

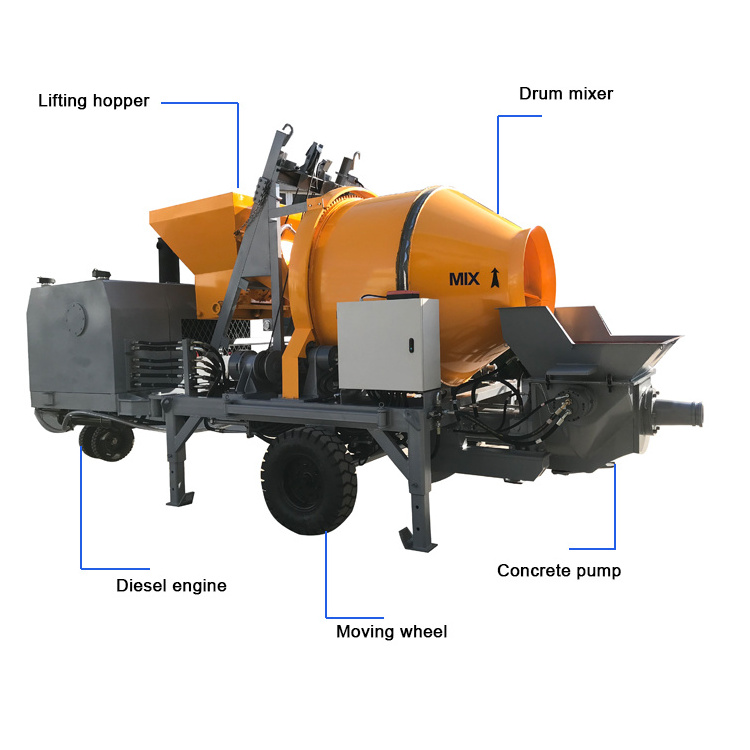

china high quality JBS40 40m3 Diesel Engine Portable Concrete Mixer Pump with trailer for Sale

Concrete mixer pump is a new kind of engineering equipment of the combination of concrete mixer and concrete pump.

It uses dual-cylinder hydraulic pumping system, small size and operating space and large concrete pouring and excellent characteristics of the mature and stable performance.

The product is suitable for 2 to 12-storey small building construction, and a variety of cave, roads, railway tunnels, water conservancy and hydropower engineering, geological hazards slope treatment works.

| Concrete Mixer with pump | unit | JBT40 |

| Max Theoretical Concrete Output | m 3 /h | 40 |

| Max Concrete outlet Pressure | Mpa | 13 |

| Concrete slump | mm | 120-230 |

| Aggregate Size | mm | less than 40 |

| Power | kw | Diesel engine 66-82 |

| Speed | r/min | 2300 |

| Concrete Cylinder Diameter | mm | 180/1050 |

| Engine Brand | huadong | |

| Main oil pump | Kawasaki | |

| Hydraulic valve | Bolseen | |

| Hydraulic hose | Manuli | |

| Main electric element | Schneider | |

| PLC Control computer | Omron | |

| Hopper Capacity | m 3 | 0.4 |

| Filling Height | mm | 1400 |

| Max Theoretical Conveying Distance (Horizontal Distance/vertical ) | m | 550/150 |

| Pipe Cleaning Mode | High pressure water washing | |

| Overall Dimension | mm | 5300×1600×2200 |

| Total Weight | kg | 4500 |

| Discharging capacity | L | 500 |

| Feeding capacity | L | 750 |

| Mixing drum speed | R/min | 14 |

| Max. Travel Speed | km/h | 10 |

Advantages of our concrete mixer pump

1, Save energy

There is no need of external power source. The diesel and electric power consumes from 29KW to 82KW. There are 4-6L consumption of fuel per hour. Compared with other concrete mixer pump manufacturer, we have obvious advantages in energy saving.

2, Long lifetime with high wear resistance

Our machine adopted more wear-resisting steel palate, 8mm thickness more thicker than 5mm steel palate commonly use.

There is no need of external power source. The diesel and electric power consumes from 29KW to 82KW. There are 4-6L consumption of fuel per hour. Compared with other concrete mixer pump manufacturer, we have obvious advantages in energy saving.

2, Long lifetime with high wear resistance

Our machine adopted more wear-resisting steel palate, 8mm thickness more thicker than 5mm steel palate commonly use.

Q1: What is the use range of 40M3/H diesel agitator pumps?

A1: suitable for 6-8 story building construction, road, bridge and small hydropower station projects.

Q2: What number of lubricating oil is required?

A2: 00# or 000#

Q3: How to add material to concrete mixer pump?

A3: Load materials by manual or by wheel loader. By wheel loader to improve working efficiency. Both is ok, it is no problem.

Q4: How much diesel need to use per hour for concrete mixer pump?

A4: Diesel consumption is about 15 liter per hour.

A1: suitable for 6-8 story building construction, road, bridge and small hydropower station projects.

Q2: What number of lubricating oil is required?

A2: 00# or 000#

Q3: How to add material to concrete mixer pump?

A3: Load materials by manual or by wheel loader. By wheel loader to improve working efficiency. Both is ok, it is no problem.

Q4: How much diesel need to use per hour for concrete mixer pump?

A4: Diesel consumption is about 15 liter per hour.

Hot Searches