- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

XHD

-

Weight:

-

580 KG

-

Dimension(L*W*H):

-

1.5*1.2*14

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Stretch film cutting mode:

-

By Knife

-

Designed linear speed:

-

600M/min

-

Max width of parent roll:

-

500mm

-

Max diameter of parent roll:

-

400mm

-

Width of sub-roll:

-

50mm-500mm

-

Power(W):

-

1.5 kw

Quick Details

-

Voltage:

-

customized, Customized

-

Power:

-

4KW, 1.5KW

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XHD

-

Weight:

-

580 KG

-

Dimension(L*W*H):

-

1.5*1.2*14

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Stretch film cutting mode:

-

By Knife

-

Designed linear speed:

-

600M/min

-

Max width of parent roll:

-

500mm

-

Max diameter of parent roll:

-

400mm

-

Width of sub-roll:

-

50mm-500mm

-

Power(W):

-

1.5 kw

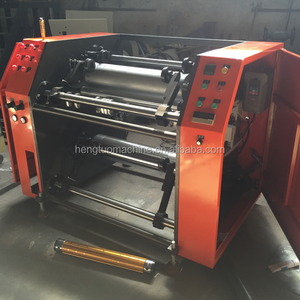

XHD Advanced Technology Slitting And Rewinding Machine For Stretch Film

Product Specification

Please check the simple information of the rewinder as below. Some cutomers would like to use certain brand (Omron, Delta, Schneider, Pro-face and Airtac) electrical parts for easy maintenance, even though the parts we are using now are very stable, we can also customize the rewinder according to customers' requirements.

|

Model No. |

XHD-500 |

| Finished Product Width | 500mm |

| Main Motor Power | 4KW |

| Linear speed | 1000m/min |

| Roll Laying Mode | Automatic |

| Degree of Automation | FulIy Automatic |

| Max Width of Parent Roll | 500mm |

| Max Width of Sub Roll | 300/350/400/450/500mm |

| Core Specification of Parent Roll | 3" |

| Core Specification of Sub Roll | 2''/3" |

| Cutting Mode | By Resistance Wire |

| Dimension | 2.6M*1.8M*1.4M |

| Weight | 0.8T |

| Application | LLDPE film/ LDPE film/ PE film/ CPE film |

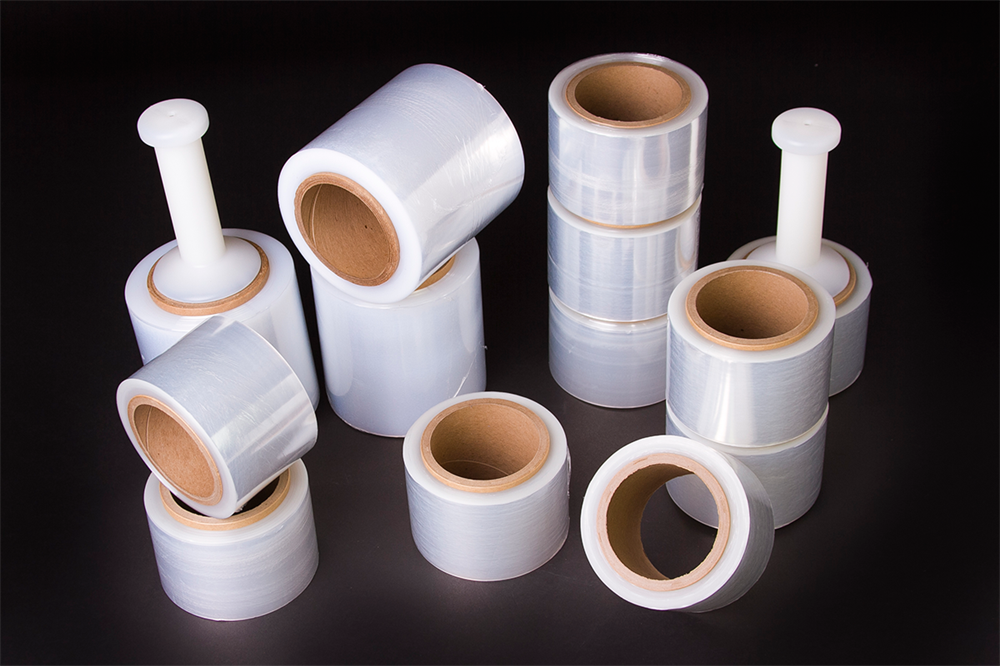

The rewinder is specially designed for rewinding master rolls with weight more than 40 KGS into small hand use stretch film rolls with 1", 1.5", 2" and 3" inner diameter paper cores. This model is very popular among our customers. A lot of our customers bought more than 3 sets, some of them even bought 10 sets. The designed speed of the rewinder is 600M/min and the maiximum production capacity is about 2 tons in 8 hours (6 tons/day).

Usage

- It is mainly used to make the big diameter volumes into small ones,to correct the wrong-layer by rewind to improve the evenness of the winding material and appearance quality

- The unit adopts flat belt transmission leak to make the load material speed the same with the leak speed

- It is also reduce the production of srcondary membrane over-stretchin, t he friction pressure controlled by the cylinder

- The units is convenient and flexible to adjust,small noise,frequency control, automatic meter winding, is the ideal cost performance winders

Work Team

FAQ

| 1. Q: Can your machine produce other kinds of film? |

| A: Yes. Our machine also can produce silage film and PE cling film. |

| 2. Q: What's the thickness range of the film produced by your machine? |

|

A: For stretch film, the thickness is from 12 microns to 30 microns. For cling film, the thickness is from 8 microns to 10 microns. For silage film, the thickness is from 15 microns to 35 microns. |

| 3. Q: Can we customize some components of the machine? |

|

A: Yes. Most of our components are from China or worldwide famous suppliers. You don't have to worry about the replacement of broken parts or the after-sale service. |

| 4. Q: When can you send the engineers for installation, debugging and training of our workers? |

|

A: It depends, but we usually arrange the engineers before the shipment. The buyer can have his machine running once he receive it. We also have some agents around the world to provide installation service or technical support. All traveling cost of the engineer the such as air tickets, food and shelter cost will be borne by the buyer. |

Related Product

| Model No. | XHD-300 |

| Motor Power | 4KW |

| Linear speed | 12Rolls(30m)/min |

| Roll Laying Mode | Automatic |

| Degree of Automation | FulIy Automatic |

| Max Width of Parent Roll | 300-350mm |

| Max Width of Syjb Roll | 300-350mm |

| Core Specification of Parent Roll | 3" |

| Core Specification of Sib Roll | Customized |

| Cutting Mode | By Resistance Wire |

| Dimension | 2.4M*1.0M*1.0M |

| Weight | 600KG |

| Application | Cling Film |

Packaging & Delivery

The semi-automatic stretch film slitter and rewinder will be packed in plywoode case (no need to do the fumigation). Please check the packing information as below. Since we had already sold the rewinders all over the world, there are some very good logistics companies for your reference.

| Packaging Details |

(1)Fully packed with PE stretch film

(2)Machine is fastened to the corners of the containers |

|---|---|

| Delivery Time | 20 working days after order confirmed |

Kind and No. of PKG: 1 PLYWOOD CASE.

Dimensions: 1.41×1.13×1.25 M

Total Volume: 2CBM

Total G.W.: 580 KGS.

The rewinder can be ready within 2~3 weeks (depends on the voltage of the machine) after receipt of the down payment.

Contact Us