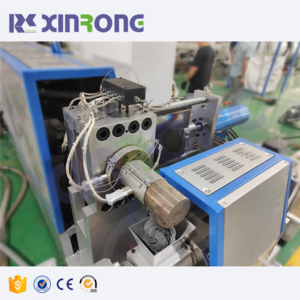

Conveying raw materials into next parts.

1. PVC/Rubber belt

2. Metal detector as an option

3. With inverter to adjust speed

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

FAMOUS

-

Application:

-

Plastic Recycling

-

Production Capacity (kg/h):

-

300 - 1500

-

Voltage:

-

According to Customer

-

Dimension(L*W*H):

-

30000*4000*3600mm

-

Power (kW):

-

350

-

Weight (T):

-

40

-

Other name:

-

PPPE Film/Bottle/Woven Bag Recycling Line

-

Key word:

-

PPPE Crushing Washing Recycling Machine

-

Category:

-

waste plastic washing recycling line

-

Quality assurance:

-

Strict testing system before delivery

-

Control system:

-

PLC

-

Material processed:

-

PP PE waste plastic films&bottles&woven bags

-

Final product:

-

Clean Plastic Films/Bottles/Woven bags

-

Final use of the Flake:

-

pppe granulating

-

Machine material:

-

SS304

-

Water consumption:

-

3-15T

Quick Details

-

Machine Type:

-

PPPE Film/Bottle/Woven Bag Washing Line

-

Max.Production Capacity (kg/h):

-

1500

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FAMOUS

-

Application:

-

Plastic Recycling

-

Production Capacity (kg/h):

-

300 - 1500

-

Voltage:

-

According to Customer

-

Dimension(L*W*H):

-

30000*4000*3600mm

-

Power (kW):

-

350

-

Weight (T):

-

40

-

Other name:

-

PPPE Film/Bottle/Woven Bag Recycling Line

-

Key word:

-

PPPE Crushing Washing Recycling Machine

-

Category:

-

waste plastic washing recycling line

-

Quality assurance:

-

Strict testing system before delivery

-

Control system:

-

PLC

-

Material processed:

-

PP PE waste plastic films&bottles&woven bags

-

Final product:

-

Clean Plastic Films/Bottles/Woven bags

-

Final use of the Flake:

-

pppe granulating

-

Machine material:

-

SS304

-

Water consumption:

-

3-15T

Product Image

|

Final Flakes Size

|

16mm (rigid Materials)80x150mm(soft Materials)or Customized

|

|

Color

|

Customer choice

|

|

After Warranty Service

|

Video technical support, Online support, Free spare parts, Field installation, commissioning and Trainning, Field Maintenance and Repair Service

|

|

Local Service Location

|

India,Saudi Arabia, Japan,South Africa,Russia,USA,Myanmar,Tunisia,Ukraine,Chile

|

|

Certification

|

CE,ISO,SGS

|

|

Transport Package

|

Wooden Case

|

|

Trademark

|

FAMOUS

|

|

Origin

|

China

|

|

HS Code

|

84778000

|

|

Supply Ability

|

30Sets/Year

|

Products Description

PP/PE Film Recycling Washing Line Machine

Product Description:

This WASTE PLASTIC PP/PE FILM RECYCLING MACHINE is designed and manufactured by our company, which is widely used for waste plastic PE/LDPE/LLDPE/HDPE film, PP woven bag, PP Jumbo bag, etc.

The waste dirty material go through crushing, friction washing, washing, dewatering, hot air drying process will turn to be clean flakes for pelletizing.

The line can be displayed "L" or "U" shape according to clients' workshop.

We can also customize the washing line components according to client's material and product requirement.

Recyclable Plastics Include:

* LLDPE/LDPE/HDPE film, crushed material

* PP/OPP/BOPP/CPP film, woven bags, jumbo bags, non-woven fabric (melt blown)

* PA66 fishing net, carpet

* PET/BOPET bottle flakes, film, waste cloth, foam, optical film

* EPS/XPS/EPE/PU/PVC crushed material, cold briquetting foam, hot melt foam, compacted foam, insulation board

* HIPS/PS/ABS home appliance housing, electronic waste, factory plastic

Product Parameters:

|

Model

|

Capacity

|

Consumption Power

|

Hot Washing

|

Water Supply

|

Manpower

|

Area Required

|

|

FMSB-300

|

300 kg/hr

|

70 kw/h

|

Optional

|

4-5 m3/hr

|

2-3 Person

|

40*4*5 m

|

|

FMSB-500

|

500 kg/hr

|

140 kw/h

|

Optional

|

6-8 m3/hr

|

2-3 Person

|

40*4*5 m

|

|

FMSB-1000

|

1000 kg/hr

|

280 kw/h

|

Optional

|

8-10 m3/hr

|

3-4 Person

|

55*6*6 m

|

|

FMSB-1500

|

1500 kg/hr

|

350 kw/h

|

Optional

|

10-15 m3/hr

|

4-5 Person

|

78*6*6 m

|

Suitable Products:

Plastic Film Recycling Washing Line Work Process:

Product Details

Function: Crushing the film/bags into small pieces, wet working with water,

can also choose shredder instead.

1. Crushing with water spraying in.

2. Knife adjustment outside chamber.

3. Low noise.

4. Bearings outside.

Function: Washing out the dirty from the film or bags material by paddles,

tank material is made by SUS304.

Function: With hot water and chemical detergent to washing off the oil,

glue and dirty(This is optional choice), machine contact the material is made by SUS304.

Function: Remove the water out from the material,

machine contact the material is made by SUS304.

Function: to squeeze and granulate wet PE film, PP woven bags,

the finally material is semi-plasticizing products,

the recycled material is more suitable for PE PP pelletizing machine.

Intelligent Control System

With CE/TUV/SGS/ISO standard, all parameters can be set on the touch screen. 1.Electric control component: (Siemens), e.g. Circuit-breaker, AC contact, press button, pilot lamp. 2.For electric control of the whole line. 3.All electrical units: Siemens, Schneider, ABB, Omron

Final Pellets For Reference

Hot Searches