- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LISHENG

-

Model Number:

-

YTC

-

Voltage:

-

380v, 220V/380V

-

Dimension(L*W*H):

-

7500*325000*4380

-

Weight:

-

8500 KG, 8700KGS

-

Printing material:

-

Paper Bopp PE Film Non Woven Fabric

-

Printing speed:

-

120m/min

-

color:

-

2\4\6\8 color

-

Thickness of Plate:

-

1.14mm, 1.7mm, 2.28mm, 2.54mm, 2.84mm

-

Delivery Time:

-

60days after receiving 30% TT desposit

-

Dimensions(L*W*H):

-

5700*2150*2950mm

-

Certification:

-

ISO9001 CE

-

After Warranty Service:

-

Field maintenance and repair service

Quick Details

-

Machine Type:

-

printing machine

-

Bag Type:

-

Fruit Bag

-

Material:

-

Plastic

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LISHENG

-

Model Number:

-

YTC

-

Voltage:

-

380v, 220V/380V

-

Dimension(L*W*H):

-

7500*325000*4380

-

Weight:

-

8500 KG, 8700KGS

-

Printing material:

-

Paper Bopp PE Film Non Woven Fabric

-

Printing speed:

-

120m/min

-

color:

-

2\4\6\8 color

-

Thickness of Plate:

-

1.14mm, 1.7mm, 2.28mm, 2.54mm, 2.84mm

-

Delivery Time:

-

60days after receiving 30% TT desposit

-

Dimensions(L*W*H):

-

5700*2150*2950mm

-

Certification:

-

ISO9001 CE

-

After Warranty Service:

-

Field maintenance and repair service

Product Description

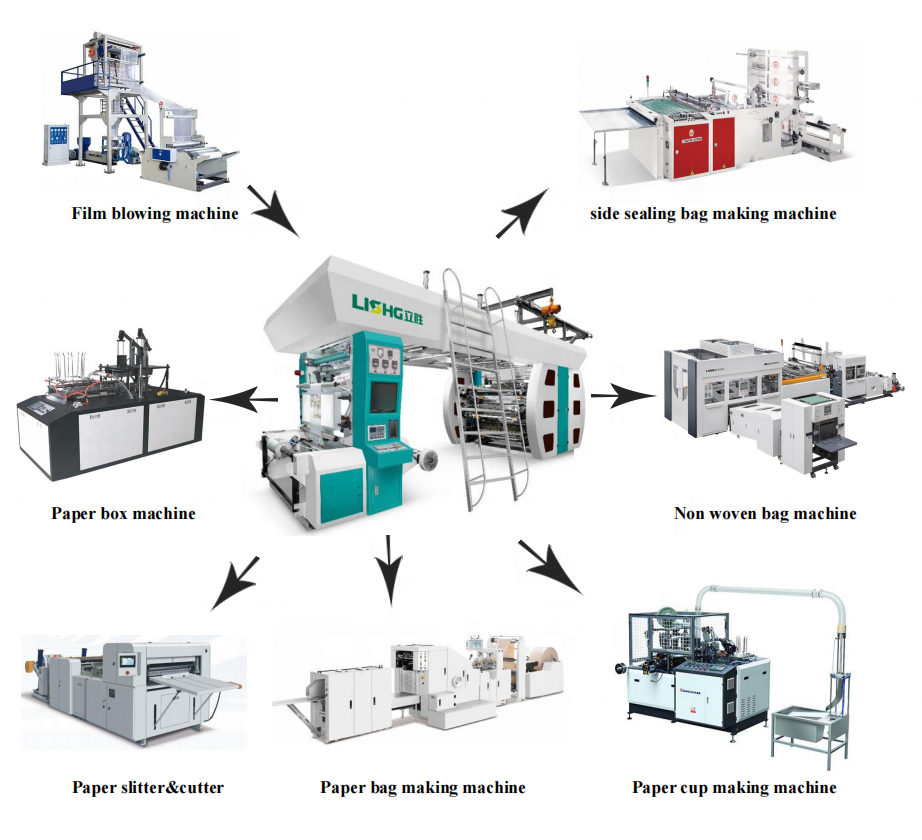

This central impression (central drum)flexographic printing machine is suitable for printing such packing materials as

paper material between 20--200gsm.And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, non-woven bag, vest bag and clothes bag, etc.

paper material between 20--200gsm.And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, non-woven bag, vest bag and clothes bag, etc.

|

Model

|

|

YTC-41000

|

|

|

|||

|

Material Feeding Width

|

|

1000mm

|

|

|

|||

|

Max Printing Width

|

|

960mm

|

|

|

|||

|

Material

|

|

Paper roll to roll 20--200gsm

|

|

|

|||

|

Thickness of plate

|

|

Resin or rubber plate, 1.7mm, 2.54mm can be customized

|

|

|

|||

|

Printing length

|

|

Customized is available from 300-1000mm

|

|

|

|||

|

Maximum machine speed

|

|

150m/min

|

|

|

|||

|

Printing Speed

|

|

80--120m/min

|

|

|

|||

|

Register precision

|

|

±0.15mm

|

|

|

|||

|

Structure type

|

|

Central impression(central drum), Gear drive

|

|

|

|||

Main Features

1) Central impression type printing machine with better color registration. Due to the big drum, the printed material is

supported by the big drum, and greatly improving color registration, especially with extensible materials.

2) All colors printing station drived by the central drum, Less transmission errors because of less gear transmission, increase

the registration precision.

3) Adopting high-quality motor, high-quality inverter, save the electricity, reduce the run fluctuation.

4) The machine is equipped with blower and heater; and the heater employed central temperature control system,

automatic temperature controller, and separated heat source.

5) The use of individual drying oven and cold wind system can effectively prevent the ink adhesion after printing.

6) Roller adopts special steel processing, and through special treatment, greatly reduce the beating range.

7)Printing roller uses static balance and dynamic balance processing, hard anode oxidation treatment, small resistance,

beating small, achieves finally perfect printing effect.

8)Accurate printing effect achieved by special gear transmission device.

9)The printing machine all can choose advance configurations to achieve the high quality, the high-definition effect.

supported by the big drum, and greatly improving color registration, especially with extensible materials.

2) All colors printing station drived by the central drum, Less transmission errors because of less gear transmission, increase

the registration precision.

3) Adopting high-quality motor, high-quality inverter, save the electricity, reduce the run fluctuation.

4) The machine is equipped with blower and heater; and the heater employed central temperature control system,

automatic temperature controller, and separated heat source.

5) The use of individual drying oven and cold wind system can effectively prevent the ink adhesion after printing.

6) Roller adopts special steel processing, and through special treatment, greatly reduce the beating range.

7)Printing roller uses static balance and dynamic balance processing, hard anode oxidation treatment, small resistance,

beating small, achieves finally perfect printing effect.

8)Accurate printing effect achieved by special gear transmission device.

9)The printing machine all can choose advance configurations to achieve the high quality, the high-definition effect.

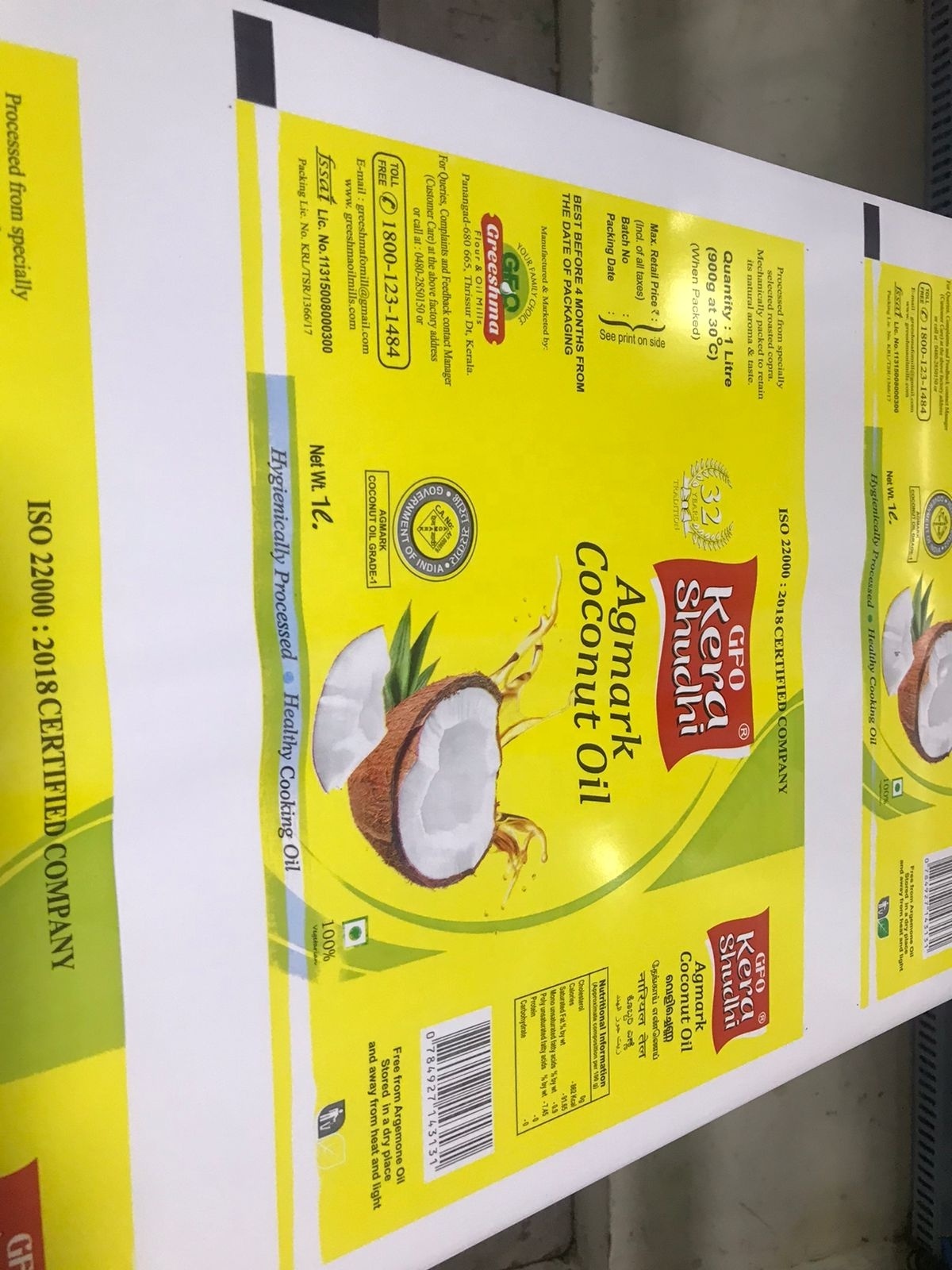

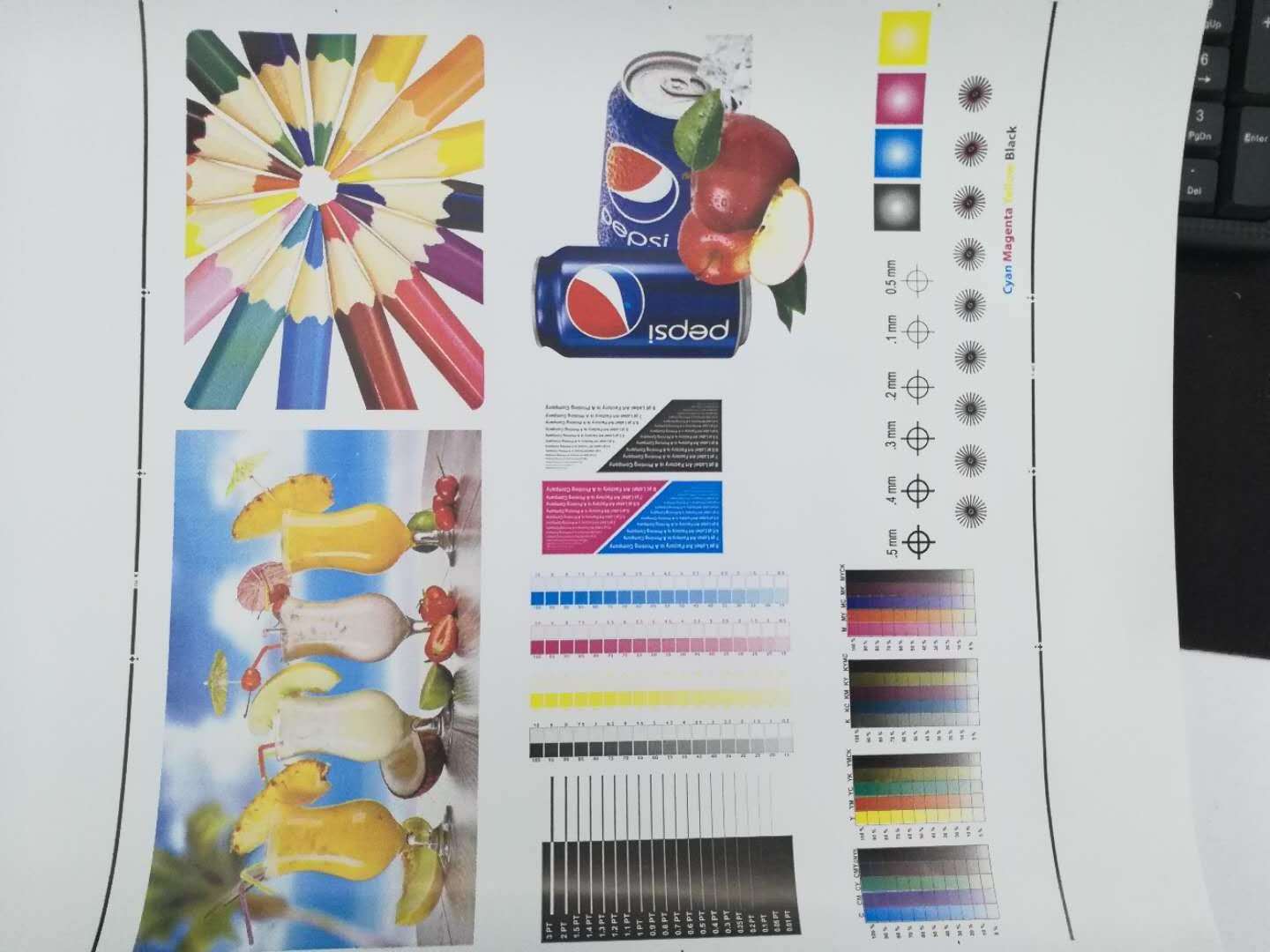

Sample pictures

Exhibition and Certification

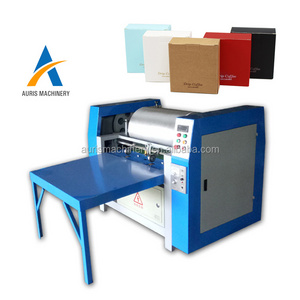

Related Products

Contact information

Our Team

Packing & Delivery

Delivery Time And Payment Terms

Within 45 working days after recieve 30% T/T deposit, then the balance be paid after satisfy test in seller's fsctory before delivery.

Hot Searches