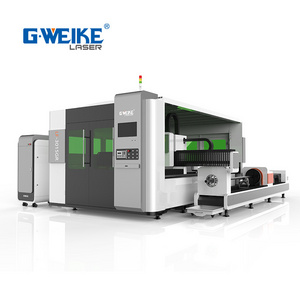

ness and ductility. The lightweight and high rigidity of the cross beam ensure the high-

speed movement during laserprocessing.

At the same time, it has perfect dynamicperformance and meets the accuracy. With long service life, it can keep the shape unchanged to the greatest extent, so as to

ensure the cutting accuracy and product quality.

ensure the cutting accuracy and product quality.