- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

Refer to parameters

-

Weight:

-

1 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Production Name:

-

Spiral Chute

-

Height of Spiral Chute:

-

1500~5230 mm

-

Feeding size of Spiral Chute:

-

0.02~0.3 mm

-

Mine density (%):

-

25%~55 %

-

Quality of Spiral Chute:

-

Pass the test

-

External diameter of Spiral Chute:

-

460~1560mm

-

Market of Spiral Chute:

-

Popular in Africa,European,Asia,etc

-

Service Life of Spiral Chute:

-

Longer

-

Advantage of Spiral Chute:

-

High efficiency

Quick Details

-

Production Capacity:

-

Max 15-40 t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Baichy Spiral Chute

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

Refer to parameters

-

Weight:

-

1 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Production Name:

-

Spiral Chute

-

Height of Spiral Chute:

-

1500~5230 mm

-

Feeding size of Spiral Chute:

-

0.02~0.3 mm

-

Mine density (%):

-

25%~55 %

-

Quality of Spiral Chute:

-

Pass the test

-

External diameter of Spiral Chute:

-

460~1560mm

-

Market of Spiral Chute:

-

Popular in Africa,European,Asia,etc

-

Service Life of Spiral Chute:

-

Longer

-

Advantage of Spiral Chute:

-

High efficiency

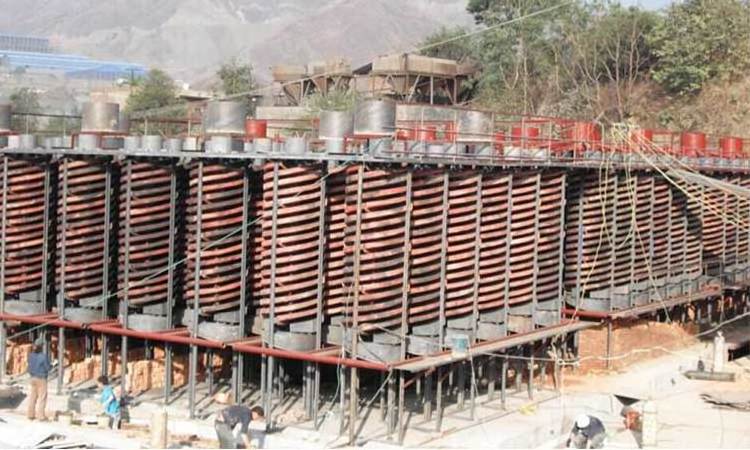

Introduction of spiral chute

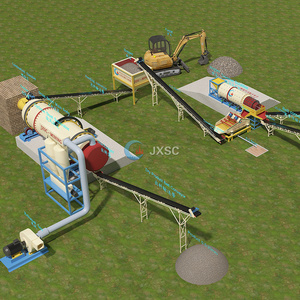

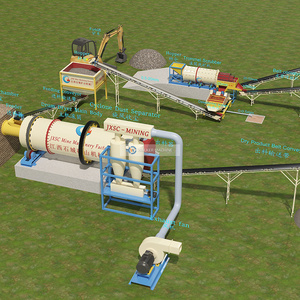

Spiral chute is the best concentrating equipment, especially for concentrating sand ore in seashore and riverside. It is made of the fiberglass lined with wear-resistant polyurethane and corundum cover; The advantages are light, moisture proof, and anti-rust,corrosive proof and no noise, properly suitable for the different feeding particle sizes and grades. The separator machine is a gravity spiral separating machine. The slurry produced inertia centrifugal force in rotary motion, and with gravity help in the same time, to promote light and heavy mineral zonation in the spiral chute, and continuous discharge respectively.

Features of spiral chute

1. Reasonable structure and small occupation area

2.High recovery, high efficiency, and precise separation

3. Non-required power

4.Light in weight, anti corrosion, rust and wear resistant

5. Simple installation and Minimal maintenance requirements

6. Low operating cost and long working life

7. Reliable running with minimal operator attention

8. Strong adaptability to fluctuation of feeding amount, density, size and grade

9. The surface of corundum forms strong friction the concentration effect surpass plastic surface

Application of gravity separator machine spiral chute for chrome separation plant :

Spiral chute concentrator is widely used to the separation for mineral particles, the size of which ranges from 0.3 to 0.02 mm. it can be suitable for dealing with different kinds of ores, such as below:

-Rutile, ilmenite and zircon concentration.

- Iron ore, chromite and manganese beneficiation.

-Tin, tantalum and ore concentration.

-Gold, native copper and base metal recovery.

-Silica sands processing.

-Titano-magnetite concentration.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 Types of Gold Ore

Gold exists in quartzite. Usually, quartz appears as small stones in large cracks in riverbeds or mountain slopes and has crystals in different colors such as white, yellow, pink, purple, gray, or black. The most common types of quartz with gold ore are rose quartz gold ore and rainbow gold ore. A high gold-quartz ore contains 25% gold by mass, and it occurs in areas where the bedrock is fractured by tectonic and volcanic activity.Flow chart of gold ore processing

Placer gold ore with high gold content mostly exists in the form of particles. Therefore, the ideal method to process placer gold ore is gravity separation.

1. Are you manufacture or trading company?

We are factory, established in 2003.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at lowest cost.

5. If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.