- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

SALONI

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

450*550*950 mm

-

Weight:

-

65 KG, 65 kg

-

use:

-

peanut sheller

-

Power:

-

2.2 kw

-

voltage:

-

220 v

-

Capacity:

-

150 kg/h

-

Size:

-

450*550*950 mm

-

Breakage rate:

-

< 2%

Quick Details

-

Type:

-

Food Machinery

-

Use:

-

Sheller

-

Production Capacity:

-

200kg/h

-

Place of Origin:

-

China

-

Brand Name:

-

SALONI

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

450*550*950 mm

-

Weight:

-

65 KG, 65 kg

-

use:

-

peanut sheller

-

Power:

-

2.2 kw

-

voltage:

-

220 v

-

Capacity:

-

150 kg/h

-

Size:

-

450*550*950 mm

-

Breakage rate:

-

< 2%

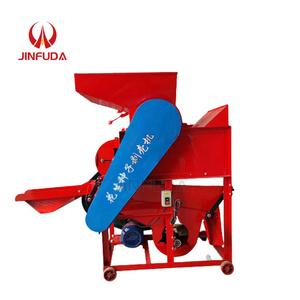

peanut shelling machine

1. description and function of peanut shelling machine

Peanut sheller is a popular product developed by the factory according to the current demand of peanut market. Its main characteristics are low broken rate, clean sorting, good color, less impurities, and all indicators meet the standard. Our factory has strong technical force, complete equipment, advanced process detection means, and is highly praised by the majority of users with high-quality products and considerate services. We will, as always, follow the business tenet of "quality and credibility first" to make our products enter thousands of households.

Working principle: peanuts are fed manually. Due to the rubbing force between the rotation of the plate and the concave plate of the fixed grid bar, the peeled peanuts and shells will fall through the grid at the same time, and then most of the peanuts will be blown out of the machine by the wind through the air duct. The peanuts and some of the peanuts that have not been peeled will fall into the specific gravity screening screen together. After re-screening, the peanuts will go up from the separating screen surface and flow into the sacks through the material opening, The peanuts (small fruits) that have not yet been peeled will go down from the screen surface, flow into the elevator through the outlet, and then be sent into the fine grain grid by the elevator for secondary shelling, and then be sorted through the specific gravity branch screen to achieve full peeling. This machine integrates peanut shelling and shell and kernel separation, and has the characteristics of simple structure, convenient operation, low power consumption and low noise. No noise, no dust (no mask and cap for peeling), the shelling rate reaches 99%, and it is very clean. This machine is durable and has a long service life

2. the technical parameter of peanut shelling machine

|

Model |

Sa - hsbkj- 350 |

|

use |

peanut shell er |

|

Power |

2.2 kw |

|

voltage |

220 v |

|

Capacity |

150 kg/h |

|

Size |

450*550*950 mm |

|

Weight |

65 kg |

|

Breakage rate |

< 2% |

3. the feature of peanut shelling machine

1) The peeling roller adopts the principle of rotary dry peeling with wooden roller and grading and seed selection with electric screen.

2) The shelling roller is made of high-quality imported wood, with a very low rate of seed damage. The shell is made of iron plate powder spraying technology, which is beautiful, generous and durable.

3) The motor voltage is 220V and the power is 2.2-4.8KW. The new copper wire motor has a longer service life.

4) The specially designed hair dryer has moderate wind power and uniform wind power distribution, which can effectively separate the seeds from the shell and optimize the seed recovery rate.

5) The sheller is equipped with high-quality directional wheels, and adopts a unique side-mounted design, which is convenient to move.

6) Compact, efficient and convenient. The peeling rate can reach more than 99%

1.

What are your advantages compared with your competitors?

With rich industry experience and strict Product Quality Control systems, we provide

1) Stable and reliable product at reasonable price)

2) Good customer service: Fast response to any inquiry or question

3) on-time delivery

2.Are you manufacturer?

Yes, we are manufacturer with more than 10 vears' experience

3.About customization

OEM business partner will be warmly welcome

4.How to order?

Inquiry >>confirmation>>payment>delivery

5.Do you have Mog?

Our MOQ is one set

Pre- service before sale

we keep 24hours online,and reply you in time ,you can send inquiry by email or any online chatting tools

and professional to introduce our machine detail and catalogue

Service during the sale

1. keep post the producetion schedule .

2. test new machine,and send you vedio and machine detail

3.packed with wooden case as export standards after you confrimed

4. delivery on time :

if by ship : we will send machine to your seaport, let you know ETD&ETA,

and send your do customs clearance documents

if by Express: we will send machine to your address(DHL,Fedex,TNT) or by air to your airport.