- Product Details

- {{item.text}}

Quick Details

-

Printing Type:

-

Screen Printing Machine

-

Weight (KG):

-

15

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SUNSHINE

-

Product name:

-

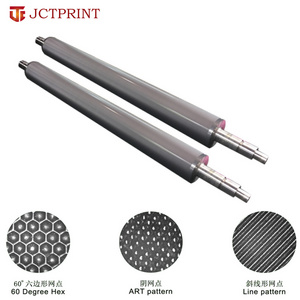

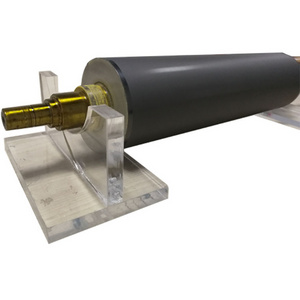

Flexo printing machine parts ceramic anilox roller

-

Printing type:

-

All kinds of flexo machine

-

Series:

-

Anilox roller

-

Characteristic:

-

High quality and longer life expectancy

-

MOQ:

-

1 Piece

-

screen count range:

-

80-2000 LPI

-

Screen angle:

-

1-89 degree

-

Usage:

-

Flexo printing

-

Model:

-

ceramics

-

Use for:

-

print

Quick Details

-

Condition:

-

New

-

Type:

-

Roller

-

Use:

-

For Heidelberg Printer

-

Printing Type:

-

Screen Printing Machine

-

Weight (KG):

-

15

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SUNSHINE

-

Product name:

-

Flexo printing machine parts ceramic anilox roller

-

Printing type:

-

All kinds of flexo machine

-

Series:

-

Anilox roller

-

Characteristic:

-

High quality and longer life expectancy

-

MOQ:

-

1 Piece

-

screen count range:

-

80-2000 LPI

-

Screen angle:

-

1-89 degree

-

Usage:

-

Flexo printing

-

Model:

-

ceramics

-

Use for:

-

print

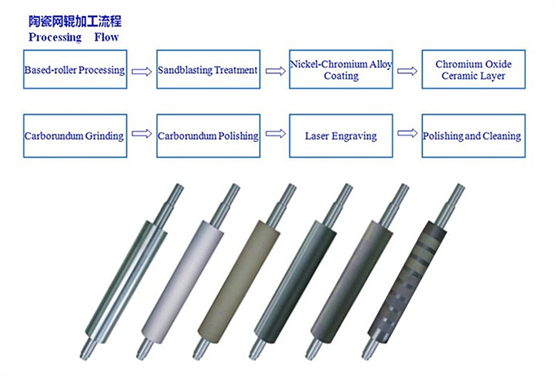

As the leading manufacturer of flexo graphic laser engraving ceramic anilox,printing cylinders and other relevant products in connection with flexo, our mission is to serve flexographic printing companies in and abroad with good quality and best service.

Now let us introduce our main production process and the reasons for you to choose us.

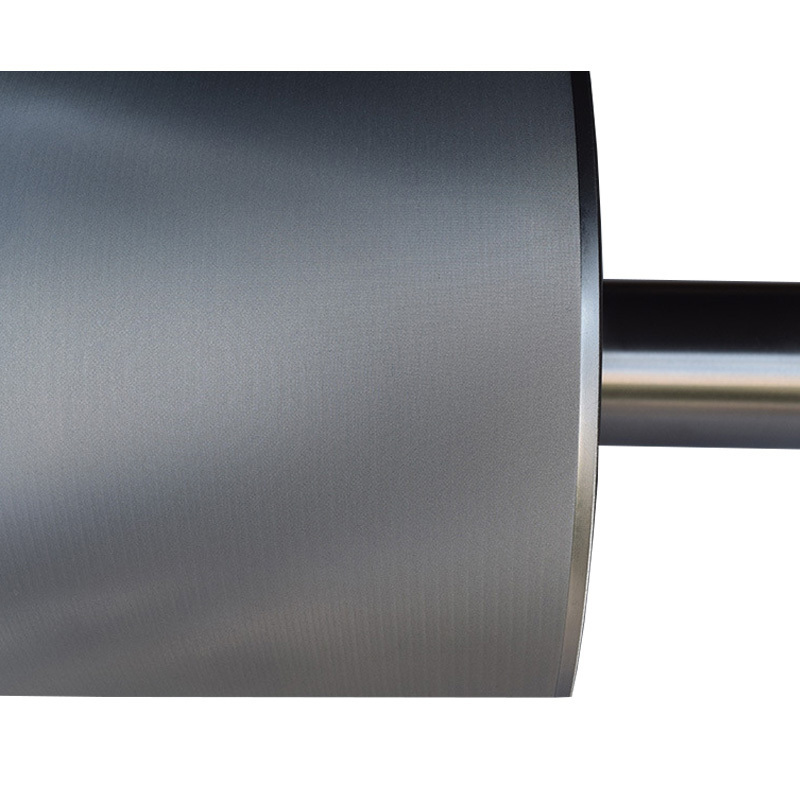

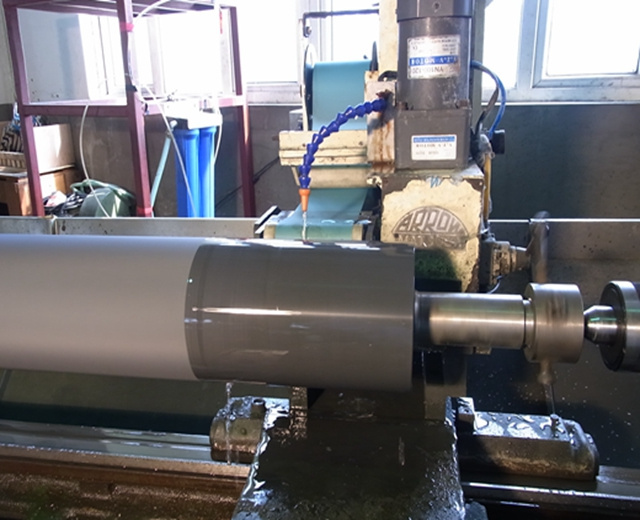

1.Base roller process:

All the base rollers are produced by ourself. For the base roller, normally we adopt the #45 seamless steel tube and the thickness is from 15mm-25mm based on the dimension of the roller. And we can also make the special thickness according to customers requirement. But normally the above mentioned information is enough for the long life use of finished products.

And we can also use No5 series aluminum as the base roller if the customer has the requirement on the weight to be light enough.

We will check all the dimensions according to customer confirmed drawing, surface roughness, straightness, dynamic balance, cylindricity and so on. If there is any small problem on these information we will not use the roller for next step but to make a new one to make sure the quality.

2.Ceramic spraying

We are using the famous plasma spraying machine and it is from Switzerland Oerlikon.And the chrome oxide ceramics we are using are also from this supplier and it can reach a hardness 1200HV. The advantage of this supplier’s ceramic powder is the evenness degree can be controlled well, 80% can be between 15u-35u but other brand especially the brand made in China only 30% can be controlled between 15u-35u.

3.Antiseptic treatment

It is easily for the ceramic anilox rollers to reach the solvent with corrosion. Once the solvent reached the base roller, it will be corroded bubble then we can not use it any more. But because we use the nanoscopic sealant to coat on the surface of the ceramic. And this kind of sealant can reach the tiny cell so it can realize a good production against the corrosion.

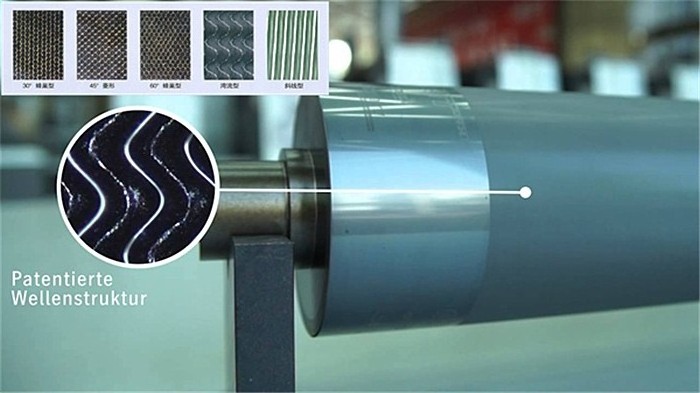

4.Precise delivery on the inks

For each roller, we will make the trial engraving before the real engraving. And after that we will use the scanner to scan each layer to test the volume of the cell then according to the realationship between the LPI and BCM to make sure the LPI we would like to reach.

5.Quality Control

We have the quality control system during the whole production from the very beginning to the end and our principle is to make sure each roller is qualified.

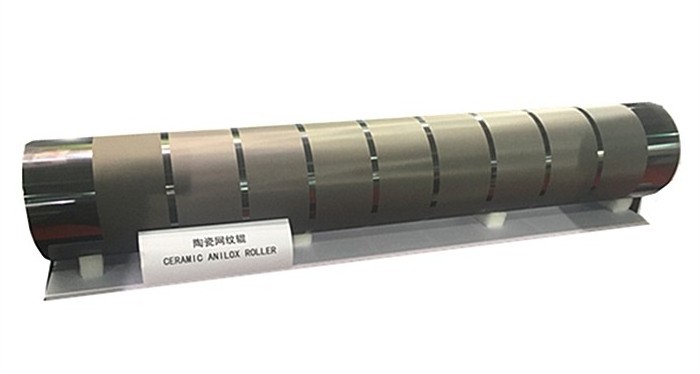

Pictures Showing:

We have two types of packaging wooden box and strong carton.

Need according to drawing to quote: