- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1500*1810*1440mm

-

Weight:

-

1700 KG

-

Place of Origin:

-

Japan

-

Voltage:

-

AC 200-415V 3 phase

-

Power:

-

2.2kVA

-

Key Machines:

-

PLC, Motor

-

Product name::

-

JUKI Pick and Place Machine

-

Optimum::

-

47,000CPH

-

Apparent power::

-

2.2kVA

-

Mass(approximately)::

-

1,700kg

-

Air consumption::

-

200L/min for internal vacuum generator

-

PCB size::

-

2500mm

-

Quality::

-

High

-

Package::

-

Vacuum Wooden Box Packaging

Quick Details

-

Machinery Capacity:

-

47,000CPH

-

Brand Name:

-

JUKI

-

Year:

-

2024

-

Dimension(L*W*H):

-

1500*1810*1440mm

-

Weight:

-

1700 KG

-

Place of Origin:

-

Japan

-

Voltage:

-

AC 200-415V 3 phase

-

Power:

-

2.2kVA

-

Key Machines:

-

PLC, Motor

-

Product name::

-

JUKI Pick and Place Machine

-

Optimum::

-

47,000CPH

-

Apparent power::

-

2.2kVA

-

Mass(approximately)::

-

1,700kg

-

Air consumption::

-

200L/min for internal vacuum generator

-

PCB size::

-

2500mm

-

Quality::

-

High

-

Package::

-

Vacuum Wooden Box Packaging

Products Description

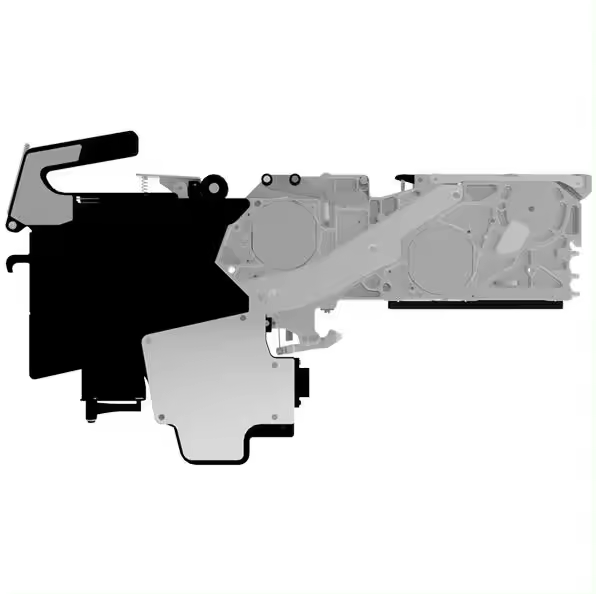

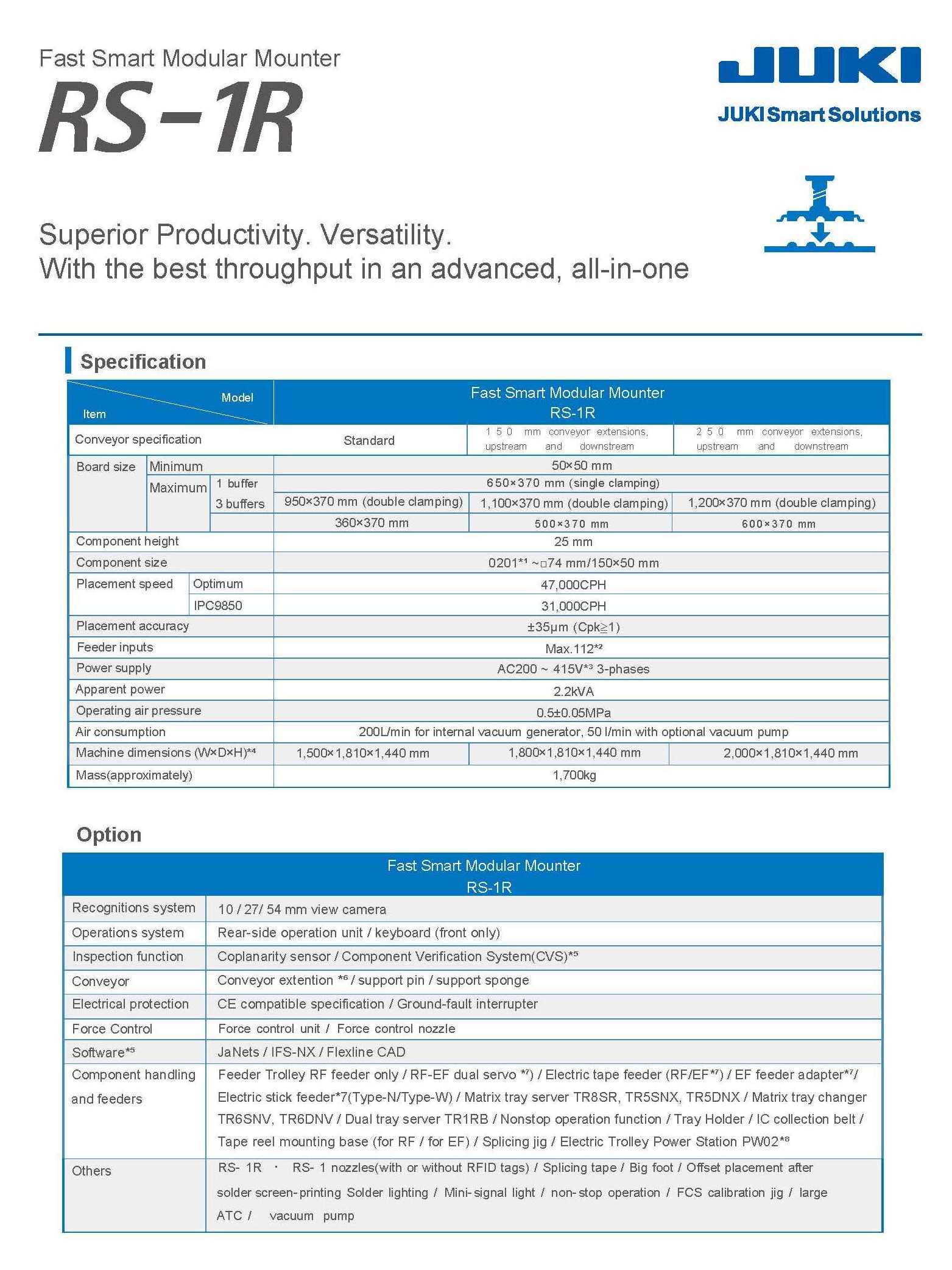

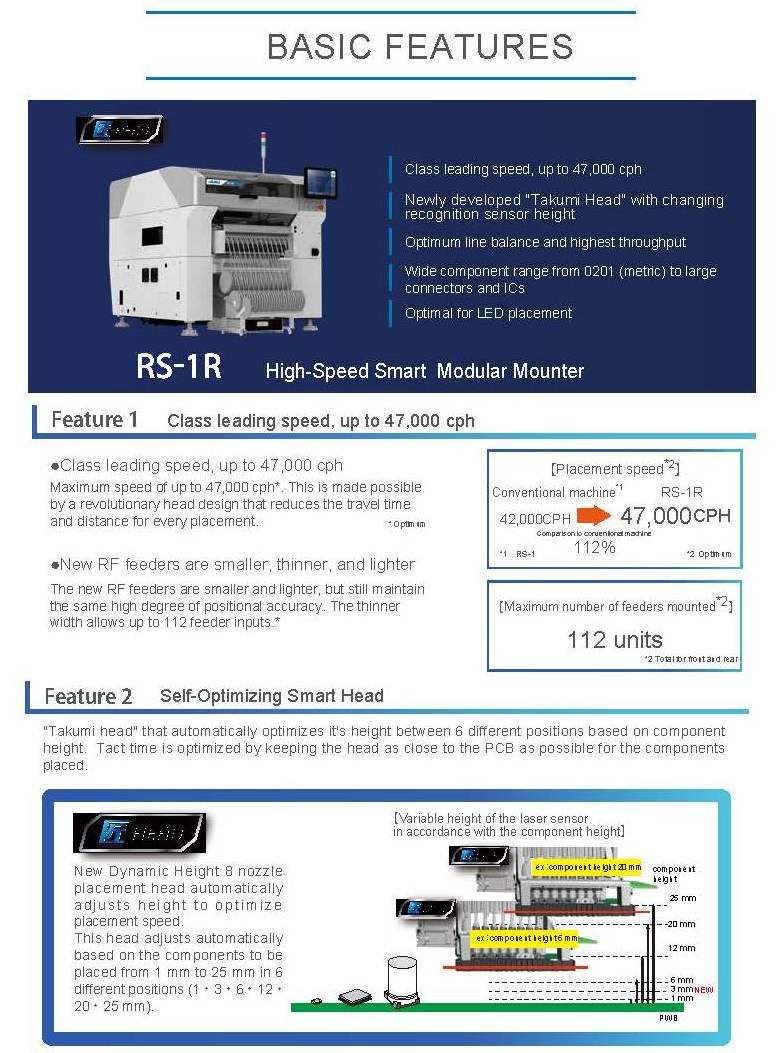

JUKI Fully Automatic High-speed intelligent Chip Mounter RS-1R SMT pick and place machine for SMT Factory PCB assembly machine.

Description

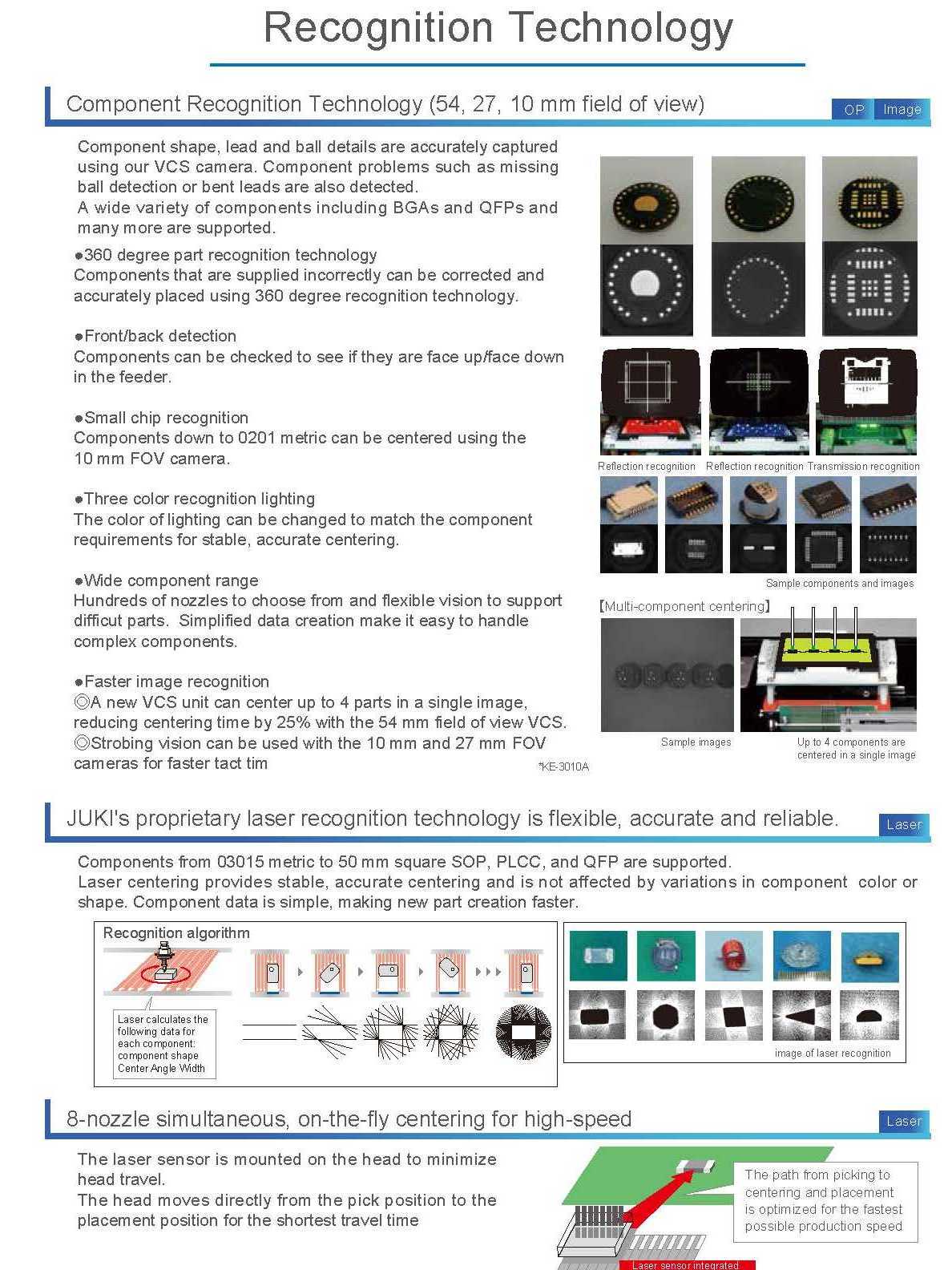

Pick and place machines are used for PCB assembly where they take components in reels or tubes or on flat packs and place them on the board as defined by software generated from the PCB files.

Features

1. Class leading speed, up to 47,000 cph

2. Newly developed “Takumi Head” with changing recognition sensor height

3. Optimum line balance and highest throughput

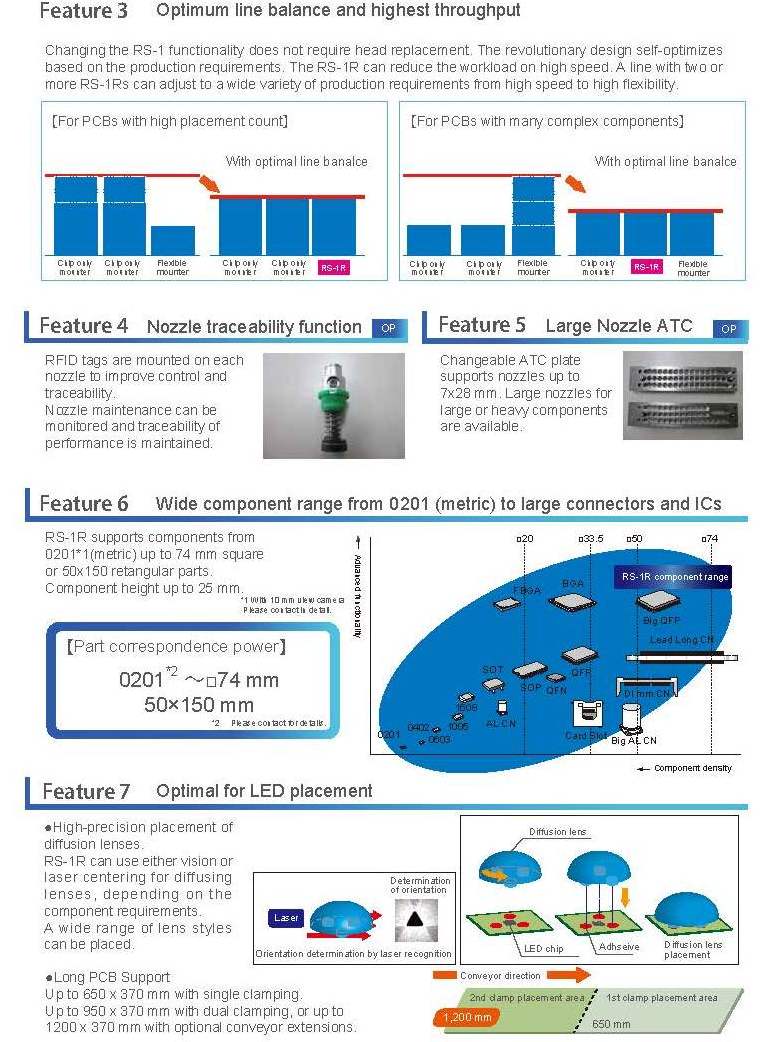

4. Wide component range from 0201 (metric) to large connectors and ICs

5. Optimal for LED placement

|

Specifications

|

|

|

|

|

||||

|

Conveyor specification

|

Standard

|

150 mm conveyor extensions, upstream and downstream

|

250 mm conveyor extensions, upstream and downstream

|

|

||||

|

Minimum Board size

|

50×50 mm

|

|

|

|

||||

|

Maximum Board size

|

1 buffer for 650×370 mm(single clamping)

|

|

|

|

||||

|

Maximum Board size (3 buffers)

|

950×370 mm(double clamping)

|

1,100×370 mm(double clamping)

|

1,200×370 mm(double clamping)

|

|

||||

|

Component height

|

25 mm

|

|

|

|

||||

|

Component size

|

0201*¹ ~□74 mm/150×50 mm

|

|

|

|

||||

|

Placement speed

|

47,000CPH(Optimum) 31,000CPH(IPC9850)

|

|

|

|

||||

|

Placement accuracy:

|

±35μm(Cpk≧1)

|

|

|

|

||||

|

Feeder inputs

|

Max.112*²

|

|

|

|

||||

|

Power supply

|

AC200 ~ 415V*³ 3-phases

|

|

|

|

||||

|

Apparent power

|

2.2kVA

|

|

|

|

||||

|

Operating air pressure

|

0.5±0.05MPa

|

|

|

|

||||

|

Air consumption

|

200L/min for internal vacuum generator, 50 l/min with optional vacuum pump

|

|

|

|

||||

|

Machine dimensions (W×D×H)*⁴

|

1,500×1,810×1,440 mm

|

1,800×1,810×1,440 mm

|

2,000×1,810×1,440 mm

|

|

||||

|

Mass(approximately)

|

1,700kg

|

|

|

|

||||

Welcome to

Shenzhen Censtar Technology Co., Ltd.,

your premier source for high-quality SMT & DIP PCB assembly line machines. With a specialized engineering team dedicated to designing and manufacturing our products, we are experts in customized solutions for PCB conveyor, PCB loader, PCB unloader, PCB buffer, wave solder infeed/outfeed, Surface cleaning machines, PCB shuttle conveyor, Semi-auto solder paste printers, PCB Transform Track Conveyor and much more. Our machines are built to the highest standards, using the latest technology and materials to ensure their durability and long lifespan. And our knowledgeable and friendly staff is always on hand to provide the support and expertise you need to get the most out of your investment.

Our success is a result of our dedication to quality and customer satisfaction. We have served customers in 37 countries around the world, helping them to build new factories and train over 450 experts and technicians. We are committed to being the most reliable Chinese partner for our customers, providing them with the support they need to achieve their goals.

At Shenzhen Censtar Technology Co., Ltd., we take pride in our attention to detail and commitment to delivering products that are both reliable and high-performing. Our experienced team of engineers and technicians work tirelessly to ensure that every product is manufactured to the highest quality standards, and we provide comprehensive after-sales support to ensure that our customers are completely satisfied with their purchase.

Whether you are looking for customized solutions for your PCB assembly line or simply seeking advice and support, we are here to help. Contact us today to learn more about how we can help you achieve your goals and take your business to the next level!

What can we do for you?

We can provide PCB inspection Conveyor, PCB Loader, PCB Unloader, PCB Buffer, Wave Solder Infeed, Wave Solder Outfeed, PCB Surface Cleaning Machine, PCB Transform Track Conveyor, etc. Professional technical support and service.

When is your delivery date?

The delivery date is about 10-15 working days after receipt of payment.

What are your payment terms? TT 100% advance payment.

Is this machine easy to use? If I have no experience, can I operate it well?

Yes, our machine is easy to use. Usually, you need 1 day to leam how to operate it. If you are a technician, then the learning period will be faster.

Do you provide user manuals and operating videos to support us?

We will provide an English user manual for free and an operation video. Our software is all in English.

If we come to your factory, will you provide free training?

Yes, you are warmly welcome to visit our factory and we will arrange free training for you.

When we encounter problems during operation, what services can you provide?

We can invite our engineers to your company for guidance, but you are responsible for the air tickets and accommodation, and we can also provide remote advice.

What is the payment method?

We accept payment methods: T/T, Western Union, etc.

Jack Li

Phone/Whatsapp: +86 15565059817

Email: censtartech@163.com

Website: www.censtartech.com

Factory address: Zhishengwei Science Park, No.9 Tianyang 5th Road, Dongfang Avenue, Songgang Street, Baoan District, Shenzhen City, Guangdong, China.

We can provide PCB inspection Conveyor, PCB Loader, PCB Unloader, PCB Buffer, Wave Solder Infeed, Wave Solder Outfeed, PCB Surface Cleaning Machine, PCB Transform Track Conveyor, etc. Professional technical support and service.

When is your delivery date?

The delivery date is about 10-15 working days after receipt of payment.

What are your payment terms? TT 100% advance payment.

Is this machine easy to use? If I have no experience, can I operate it well?

Yes, our machine is easy to use. Usually, you need 1 day to leam how to operate it. If you are a technician, then the learning period will be faster.

Do you provide user manuals and operating videos to support us?

We will provide an English user manual for free and an operation video. Our software is all in English.

If we come to your factory, will you provide free training?

Yes, you are warmly welcome to visit our factory and we will arrange free training for you.

When we encounter problems during operation, what services can you provide?

We can invite our engineers to your company for guidance, but you are responsible for the air tickets and accommodation, and we can also provide remote advice.

What is the payment method?

We accept payment methods: T/T, Western Union, etc.

Jack Li

Phone/Whatsapp: +86 15565059817

Email: censtartech@163.com

Website: www.censtartech.com

Factory address: Zhishengwei Science Park, No.9 Tianyang 5th Road, Dongfang Avenue, Songgang Street, Baoan District, Shenzhen City, Guangdong, China.

Hot Searches