- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

150 - 420 mm

-

Ejector Stroke(mm):

-

135 mm

-

Ejector Force(kN):

-

50 kN

-

Theoretical Shot Volume(cm³):

-

228 cm³

-

Injection Rate (g/s):

-

100 g/s

-

Injection Weight (g):

-

205 g

-

Screw Speed (rpm):

-

1 - 190 rpm

-

Screw diameter (mm):

-

40 mm

-

Screw L/D Ratio:

-

21.7

-

Distance between Tie Bars:

-

410*375mm

-

Weight (KG):

-

3900

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

350 mm

-

Model Number:

-

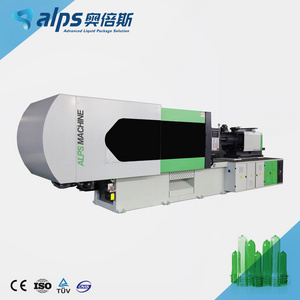

BST-1320A

-

Brand Name:

-

BEST Machinery

-

Power (kW):

-

8.2 kW

-

Product name:

-

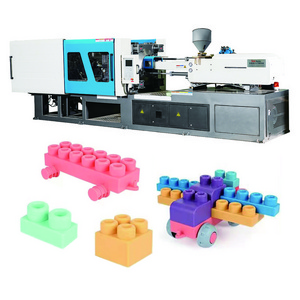

Automatic Plastic Bottle Cap Making Injection Molding Machine

-

injection pressure:

-

164-183Mpa

-

Mould thickness:

-

150-400mm

-

Ejector tonnage:

-

50KN

-

Ejector number:

-

5 Piece

-

Hole diameter:

-

100 mm

-

Max pump pressure:

-

16 Mpa

-

Machine dimension:

-

4.3* 1.5*1.6m

-

Machine weight:

-

3.4t

-

Oil tank capacity:

-

180 L

-

Certification:

-

ISO9001

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

410mm

-

Distance between Tie Bars(Height)(mm):

-

375mm

-

Plasticizing Capacity(g/s):

-

100

-

Mold Height(mm):

-

150 - 420 mm

-

Ejector Stroke(mm):

-

135 mm

-

Ejector Force(kN):

-

50 kN

-

Theoretical Shot Volume(cm³):

-

228 cm³

-

Injection Rate (g/s):

-

100 g/s

-

Injection Weight (g):

-

205 g

-

Screw Speed (rpm):

-

1 - 190 rpm

-

Screw diameter (mm):

-

40 mm

-

Screw L/D Ratio:

-

21.7

-

Distance between Tie Bars:

-

410*375mm

-

Weight (KG):

-

3900

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

350 mm

-

Model Number:

-

BST-1320A

-

Brand Name:

-

BEST Machinery

-

Power (kW):

-

8.2 kW

-

Product name:

-

Automatic Plastic Bottle Cap Making Injection Molding Machine

-

injection pressure:

-

164-183Mpa

-

Mould thickness:

-

150-400mm

-

Ejector tonnage:

-

50KN

-

Ejector number:

-

5 Piece

-

Hole diameter:

-

100 mm

-

Max pump pressure:

-

16 Mpa

-

Machine dimension:

-

4.3* 1.5*1.6m

-

Machine weight:

-

3.4t

-

Oil tank capacity:

-

180 L

-

Certification:

-

ISO9001

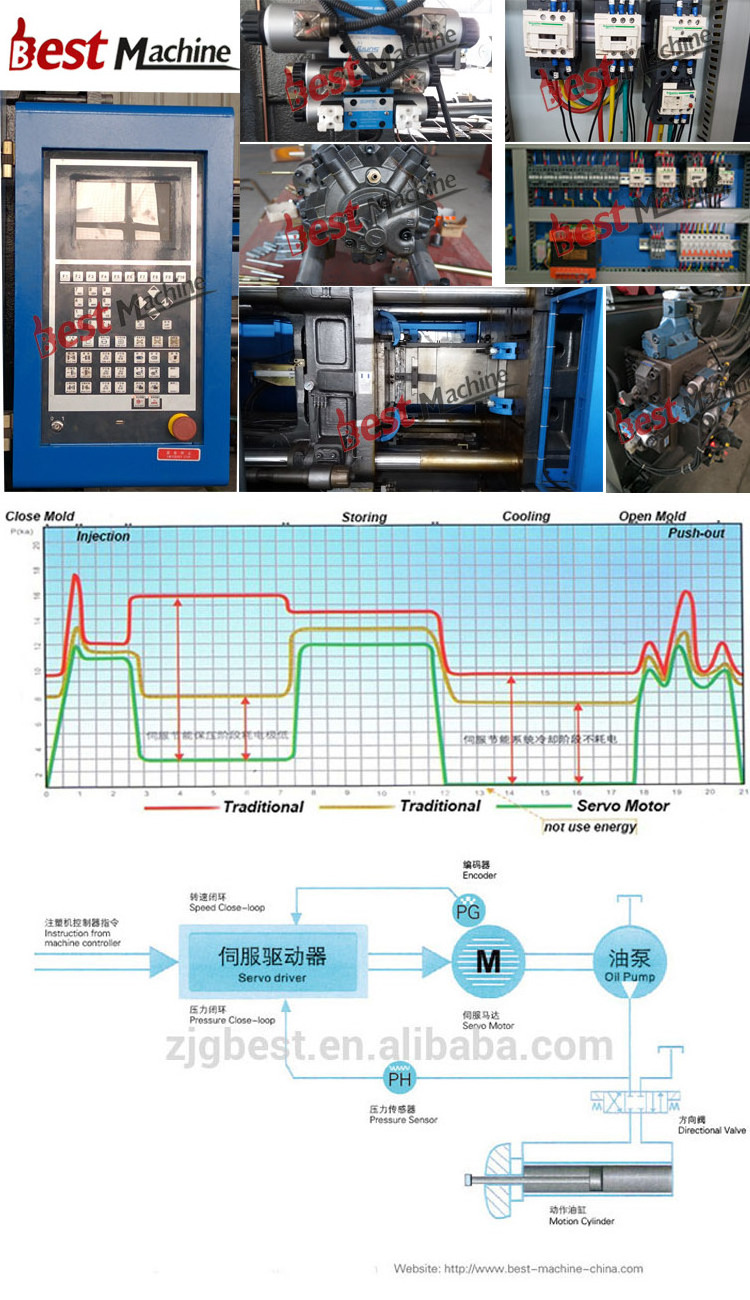

BST-1320A Injection Molding Machine:

1. 5% power reducing.

2. Multi-language interface upgrades.

3. 50% data storage: from 50 sets to 100 sets.

Strong Technical design ability, Stable quality, and large production capability, Famous brand .

Technical parameters

| Model | Clamp tonnage (KN) | Ejector tonnage (KN) | Heat power(KN) | Max.Pump pressure (MPA) | Pump motor power(kw) | Machine dinension(m) | Machine weight(t) | Oil tank capacity(L) |

| BST-1000A | 1000 | 50 | 7.6 | 16 | 11 | 4.3*1.5*1.6 | 3.4 | 180 |

| BST-1320A | 1320 |

50

|

8.2 | 16 | 13 | 4.5*1.6*1.7 | 3.9 | 200 |

| BST-1400A | 1400 | 50 | 8.2 | 16 | 13 | 4.8*1.6*1.7 | 4.2 | 220 |

| BST-1650A | 1650 | 70 | 8.2 | 16 | 15 | 5.0*1.6*1.7 | 5 | 250 |

| BST-1800A | 1800 | 70 | 11 | 16 | 15 | 5.3*1.6*1.75 | 5.5 | 250 |

| BST-2050A | 2050 | 70 | 11.6 | 16 | 17 | 5.4*1.6*1.75 | 6 | 270 |

| BST-2300A | 2300 | 70 | 11.6 | 16 | 18.5 | 5.7*1.8*2.0 | 6.5 | 300 |

| BST-2600A | 2600 | 70 | 15.5 | 16 | 25 | 6.1*1.7*1.8 | 8 | 350 |

| BST-3000A | 3000 | 80 | 15.5 | 16 | 25 | 6.5*1.8*1.8 | 9 | 370 |

| BST-3400A | 3400 | 80 | 17.5 | 16 | 30 | 6.7*2.0*1.9 | 10.8 | 400 |

| BST-3850A | 3850 | 80 | 17.5 | 16 | 30 | 7.0*2.2*2.0 | 11.5 | 400 |

| BST-4500A | 4500 | 85 | 20.5 | 16 | 37 | 7.3*2.3*2.4 | 13.8 | 450 |

| BST-4800A | 4800 | 125 | 23.4 | 16 | 40 | 8.3*2.2*2.2 | 16.2 | 600 |

| BST-5200A | 5200 | 125 | 28.1 | 16 | 43.5 | 8.6*2.2*2.25 | 20 | 750 |

| BST-5800A | 5800 | 125 | 28.1 | 16 | 48.5 | 8.75*2.2*2.3 | 21.8 | 850 |

| BST-6500A | 6500 | 160 | 37.1 | 16 | 55 | 9.2*2.2*2.4 | 26 | 1000 |

| BST-7500A | 7500 | 180 | 40.9 | 16 | 67 | 10.7*2.3*2.7 | 38 | 1200 |

| BST-8500A | 8500 | 186 | 42.5 | 16 | 74 | 11*2.4*2.75 | 45 | 1300 |

| BST-11000A | 11000 | 210 | 63 | 16 | 128 | 14*2.9*4.1 | 63 | 1800 |

| BST-13000A | 13000 | 280 | 85.25 | 16 | 160 | 13.2*3.1*3.6 | 76 | 2400 |

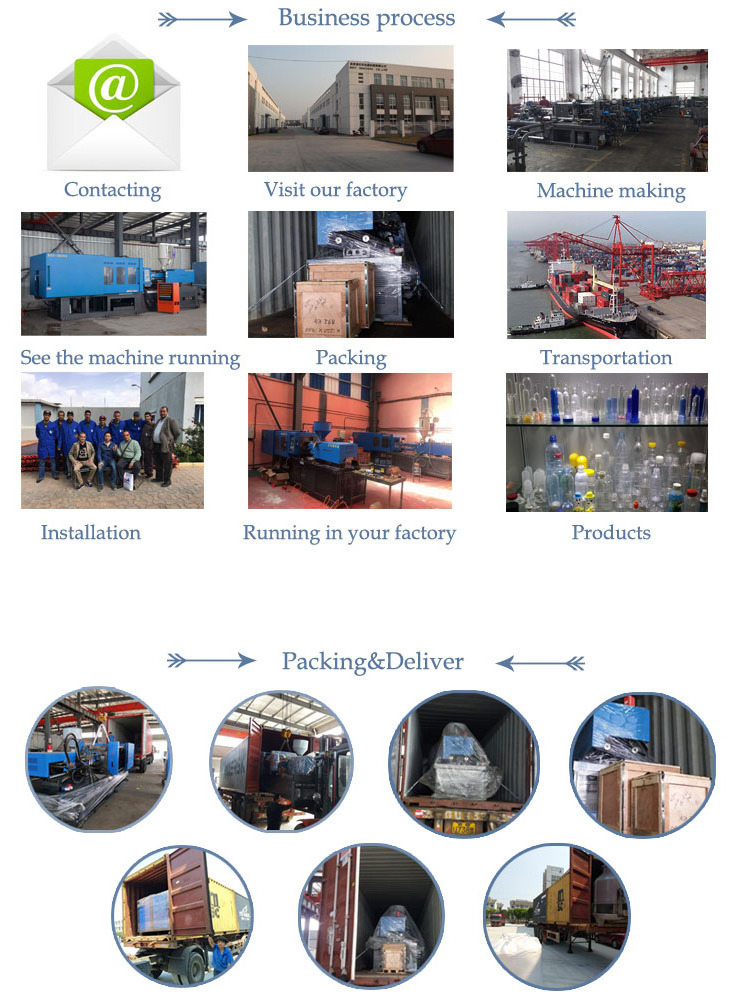

Business process

1. Inquiry-Pofessional Inquiry

2. Confirm the price, leadtime, payment term etc

3. Sheenstar sales send the proform invoice with sheenstar seal

4. Customer make the payment for deposit and send us bank receipt and offer samples

5. Inform customer has got the deposit and start to production

6. Middle production- send photos to show the production line which you can see your products in. Confirm the estimated delivery time again

7. Clients make payment for balance and Sheenstar ship the goods. Also can accept payment term-Balance against B/L Copy Or L/C payment Term. Inform the tracking number and check the status for clients.

8.Order can be say “finish” when you receive the goods and satisfy with them.

9. Feedback to Freedom about Quality , Service, Market Feedback & Suggestion. And we can do better.

Packing&Delivery

We take care of our machine packing and loading.

Injection machine with anti-rust process, make sure no rust due to ocean shipment.

Each package would be fixed stable inside container, make sure no damage or crash during whole shipment. We should take photos of loading, and send to you for reference.

When you finish the Preparation conditions,our fast and professional after - sales service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

After-sales service

• Well-trained & experienced staff are to answer all your inquiries in English and Chinese

• 24 hours for engineer response (all services part 5days in customer hand by Intl' courier).

• 1 Years guarantee

• Your business relationship with us will be confidential to any third party.

• Good after-sale service offered, please get back to us if you got any questions.