- Product Details

- {{item.text}}

Quick Details

-

Compressed medium:

-

oxygen

-

Inlet pressure:

-

1.7Mpag

-

Dimension:

-

3500*2300*1600 mm

-

Motor speed:

-

980 r/min

-

Lubrication oil temperature:

-

<40℃

-

Diaphragm disk:

-

00Cr15Ni15

-

Cylinder body:

-

45

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Product name:

-

Mini Air Compressor For Sale

-

Flow-rate:

-

300Nm3/hr

-

Compressed medium:

-

oxygen

-

Inlet pressure:

-

1.7Mpag

-

Dimension:

-

3500*2300*1600 mm

-

Motor speed:

-

980 r/min

-

Lubrication oil temperature:

-

<40℃

-

Diaphragm disk:

-

00Cr15Ni15

-

Cylinder body:

-

45

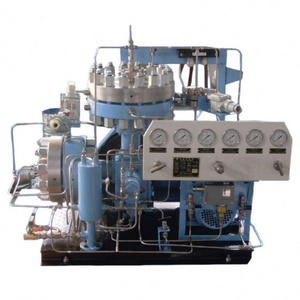

Compressor is the heart of refrigeration system, and essential device for air separation plant. As a leading manufacturer for air separation plant in China, we could provide four kinds of compressors: diagram compressor, piston compressor, and centrifugal compressor. These compressors has the advantages of high efficiency, tight structure and long time operation. These guarantee the high efficient operations of air separation plant.

Diaphagram Compressor

This compressor is a volumetric compressor with special structure. Its cylinders no need lubrication with perfect sealing performance. Medium gases will not touch with any lubrication agents, so no pollution will be produced during the procedure. This compressor is specially suitable for the transportation, delivery and cylinders-filling of rare gases; otherwise, it is good for the corrosive, harmful,explosive and radioactive gases.

Piston Compressor

Our company adopt advanced technology, the designed piston compressor finishes works by doing reciprocating motions of piston in the cylinder, gas valves as well as the gas cylinders. There are four procedures: expansion, adsorption, compression and discharge. This kind of compressor is suitable for different flow-rate and pressure; the heat efficiency rate is high with less unit power consumption; it will not be affected by the pressure;

Screw Compressor

Our screw compressors adopt high-effiency belt for driving along with the motor for rotatory. Cooling for is done through oil spray to the compressed air in the main engine. The air & oil mixed gases come out from the main engine will go through two kinds of separations and separate the oil in the compressed air and finally get the clean compressed air. We have single screw compressor and double screw compressor for your reference.

Introduction

Factory

Workshop

Annually, we produce more than 800 storage tanks and more than 20 sets of gas plants.

Advanced planer

To improve our design, we keep a technical cooperation with PRAXAIR and LINDE and benefit a lot from it. We have our own technical centers, including Sichuan Institute of Cryogenic Equipment, Welding Research Center, Engineering Technology Research Institute, etc. We have more than 100 professional inspection and test people and registered quality engineers.

Pipe prefabrication automatic welding machine

The company has standard digital management system and modern processing equipment. The equipment includes advanced digital underwater plasma cutting machine, automatic TIG welding equipment, aluminum alloy internal-external combination longitudinal-circumferential welding system (USA), etc.

Pre-sales Service

Communicate with customers, analyze their needs

Sales Service

Provide professional technical solutions, recommend the right models

After-sales Service

For different products, we can quote the EXW, FOB, CFR or CIF price accordingly

Sound packaging and timely delivery

We take different packing approaches according to specific requirements. Wrapped bags and wooden boxes are commonly used for waterproof, dust-proof and shock-proof purposes, ensuring that every equipment remains in perfect condition after delivery.

In terms of logistics, the company has a large warehouse and a unique 800 ton private-owned wharf. We can deliver 500 tons of oversized cargos directly through the canal to Shanghai port. We also have several highways near us for land transport. We are 180 km from Shanghai port and 80 km from Hangzhou Xiaoshan International Airport. Customer visit and equipment delivery are both very convenient.

Q: What products I can order from your company?

A: We specialize in producing Cryogenic Air Separation Plant, LNG plant, CO2 Recovery Plant, Cryogenic Liquid Storage Tank (LO2, LN2, LAr, LCO2 and LNG), Semi-trailer Tanker, Vaporizer, VPSA/PSA Oxygen/Nitrogen Generator, Cryogenic Liquid Pump, Gas filling Station, Compressor and dry ice making/cleaning machines etc. Any interests you can feel to contact us for details. Thanks.

Q: What is your production standard? Can you manufacture your products under ASME standard?

A: Our company has obtained the A2 and C2, C3 Pressure Vessel Fabrication Certificates, Grade GC1 Pressure Pipe& Vessel Construction Certificates, ISO9001 Quality Certificate, ASME Certificate and U Stamp. So, if you ask for ASME stamp, we are able to manufacture your products under ASME standard.

Q: Have you supplied tanks to any renowned companies?

A:

Our group company is a regular strategic partner of some big gas companies. We have supplied many storage tanks for them with different sizes. The biggest size we ever provided is 3000m3 ordinary pressure storage tank. We also made high pressure storage vessels for them, such as 100m3 LCO2 tanks, 10m3 (20m3, 30m3)LO2 (LN2, LAR) tanks.

Q: What about warranty?

A:

Equipment warranty is 12 months from the date on which the equipment is applied successfully into operation, or 14 months from the date on which the equipment has been delivered, whichever comes first.