- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

UN-M007

-

Cavity:

-

2~8 C

-

Alloy:

-

3003,3004,8006,8011,1145,6061

-

Process Combination:

-

Composite Mould

-

Composite Mould:

-

Punching and Shearing Mould

Quick Details

-

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Ungar

-

Model Number:

-

UN-M007

-

Cavity:

-

2~8 C

-

Alloy:

-

3003,3004,8006,8011,1145,6061

-

Process Combination:

-

Composite Mould

-

Composite Mould:

-

Punching and Shearing Mould

Product Description

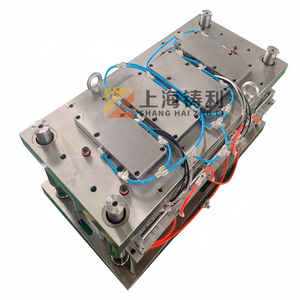

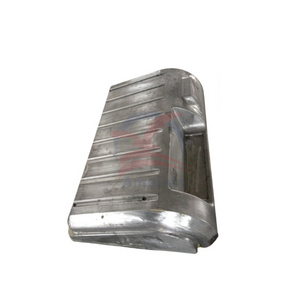

Aluminium Foil Container Mould

| Material of Mould | Steel Alloy | Origin |

| High Chrome Steel | DC53 | Japan |

| High Chrome Steel | SKD11 | Japan |

| 9CrWMn. | K460 | Austria |

| Chrome Steel | Cr12mov | China |

| Chrome Steel | Cr12 | China |

| Steel | S50C | Japan |

| Medium Steel | 45# | China |

| The die holder is made of Precise hardware steel plate covered with four column copper base steel ball | ||

| guide part(Order) | Guide part(Material) | Die Holder Material |

| MISUMI | SUJ2 | S50C (Japan) |

Technical Specifications:

1.

Mould adopt higher level Quality Steel:Cr12Mov,Cr12,DC53,SKD11 ect.

2. Mould fit Aluminum Foil Material Alloy:8011,8006,3003,3005 ect;Thickness:0.03mm--0.350mm;

3. Logo can be customized upon your request.

4.

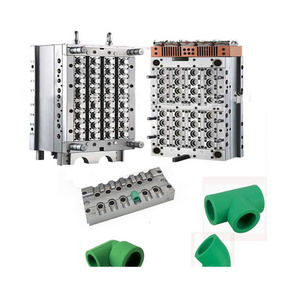

We have various molds such as airline food container mold,aluminum foil trays mold for the punching press machine.

UNGAR team are able to design and build mould for every kinds press, as well as the numbers of cavities.

UNGAR MACHINERY(SHANGHAI) CO., LTD is an Austrian enterprise established in 2009 supplying high productive multi-cavity mould and machinery which includes press, stacker, package, re-winder, paper lid cutting, decoiler, scrap aspirator and additional equipment. UNGAR complete integrated production line has been specially designed and developed for the production of aluminum food container and trays.

UNGAR MACHINERY(SHANGHAI) CO., LTD

as a technology leader focusing on researching and developing new products with a professional design team, technical department and sales group. In this way, the design team with its headquarter in Austria, manufacturing factory located in Shanghai, professional engineers service and global sales linking by Europe, America, Middle East Gul-food area and most of Asian countries.

UNGAR MACHINERY (SHANGHAI) CO., LTD also offer customized service for technical optimization, mould prove, machine installation, material test, training course, telephone assistance and so on. UNGAR more than just a manufacturer......